Introduction

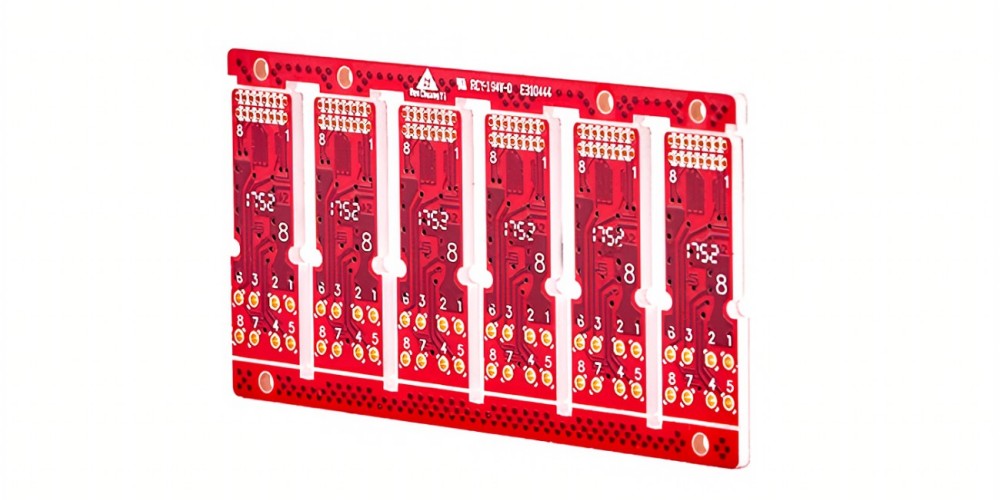

Rogers CuClad 250 is a high-performance copper clad laminate that is widely used in the production of printed circuit boards (PCBs). It consists of glass fabric reinforced epoxy resin bonded with copper foil on both sides. CuClad 250 offers excellent dimensional stability, high thermal conductivity, and good dielectric properties, making it well-suited for use in high-frequency applications.

In this article, we will take an in-depth look at Rogers CuClad 250, including its key features and benefits, material properties, common applications, and frequently asked questions.

Key Features and Benefits of Rogers CuClad 250

Rogers CuClad 250 offers several advantages that make it a popular choice for high-performance PCBs:

Dimensional Stability

With a low Z-axis expansion of 40 ppm/°C, Rogers CuClad 250 provides excellent dimensional stability during thermal excursions in PCB fabrication processes. This minimizes registration issues during multilayer bonding.

High Thermal Conductivity

With a thermal conductivity of 0.71 W/mK, CuClad 250 conducts heat efficiently in the z-axis. This allows effective heat dissipation from high power components.

Low Dielectric Constant and Loss Tangent

CuClad 250 has a relatively low dielectric constant of 3.9 at 10 GHz and low loss tangent of 0.0115 at 10 GHz. This allows increased circuit densities and high frequency operation with low signal loss.

Good Bond Strength

The resin system provides excellent bond strength between the copper foil and dielectric layer. This allows thinner copper foils to be used without risk of delamination.

Easy Processing

CuClad 250 can be processed using standard PCB fabrication techniques like photolithography, drilling, and plating. No special processing is required.

Material Properties of Rogers CuClad 250

Here are some key material properties of Rogers CuClad 250:<style> table { font-family: arial, sans-serif; border-collapse: collapse; width: 100%; } td, th { border: 1px solid #dddddd; text-align: left; padding: 8px; } tr:nth-child(even) { background-color: #dddddd; } </style> <table> <tr> <th>Property</th> <th>Value</th> </tr> <tr> <td>Dielectric Constant at 10 GHz</td> <td>3.9</td> </tr> <tr> <td>Loss Tangent at 10 GHz</td> <td>0.0115</td> </tr> <tr> <td>Z-Axis Thermal Conductivity</td> <td>0.71 W/mK</td> </tr> <tr> <td>Z-Axis Coefficient of Thermal Expansion</td> <td>40 ppm/°C</td> </tr> <tr> <td>Copper Foil Thickness</td> <td>1/2 oz. (17 μm) standard</td> </tr> <tr> <td>Glass Transition Temperature</td> <td>170°C</td> </tr> <tr> <td>Decomposition Temperature</td> <td>340°C</td> </tr> <tr> <td>Volume Resistivity</td> <td>1 x 10<sup>15</sup> ohm-cm</td> </tr> <tr> <td>Surface Resistivity</td> <td>5 x 10<sup>14</sup> ohms</td> </tr> <tr> <td>Dielectric Strength</td> <td>1000 V/mil (39 V/μm)</td> </tr> <tr> <td>Water Absorption</td> <td>0.06% 24 hours</td> </tr> </table>

Common Applications of Rogers CuClad 250

Some typical applications of Rogers CuClad 250 include:

High Frequency Circuits

The stable dielectric properties and low loss of CuClad 250 make it suitable for RF/microwave PCBs used in applications like radar, satellite communications, 5G infrastructure, etc. It allows circuits with high operational frequencies.

High Speed Digital Circuits

For multilayer boards used in servers, network switches, routers etc, CuClad 250 provides low skew and loss for high speed differential signals used in technologies like PCIe, HDMI, USB 3.0 etc.

High Power PCBs

The excellent thermal conductivity allows CuClad 250 to be used in power converter PCBs, motor drives, power supplies etc, to dissipate heat from components.

Aerospace and Defense Electronics

CuClad 250 meets aerospace OEM requirements for dimensional stability at high altitudes and temperatures. It is used for avionics equipment.

Automotive Electronics

It withstands high temperatures in engine compartments and meets automotive OEM standards. Used in engine control units, RADAR PCBs for ADAS systems.

Rogers CuClad 250 vs. Competitor Materials

Rogers CuClad 250 competes with other high frequency laminates like:<table> <tr> <th>Material</th> <th>Key Properties</th> </tr> <tr> <td>Rogers 4003C</td> <td>- Higher Dk of 3.38 vs 3.9 for CuClad 250<br>- Higher thermal conductivity of 0.89 W/mK</td> </tr> <tr> <td>Isola FR408HR</td> <td>- Comparable Dk and loss tangent<br>- Lower Z-axis CTE of 30 ppm/°C</td> </tr> <tr> <td>Taconic RF-35A2</td> <td>- Lower loss tangent of 0.0038 at 10 GHz<br>- Improved moisture absorption of 0.02%</td> </tr> <tr> <td>Arlon 85N</td> <td>- Higher thermal conductivity of 1.44 W/mK<br>- Increased Z-axis CTE of 50 ppm/°C </td> </tr> </table>

While other materials may exceed CuClad 250 on some specific properties, Rogers CuClad 250 provides the best balance of electrical performance, thermal management, and dimensional stability for most high frequency applications.

Rogers CuClad 250: Frequently Asked Questions

Here are some common questions about Rogers CuClad 250:

What are the standard thicknesses available?

Rogers CuClad 250 is available in thickness from 0.002″ (0.05 mm) to 0.062″ (1.6 mm). The most common thicknesses used are 0.004″, 0.005″, 0.008″, 0.010″ and 0.020″.

What copper weights are commonly used?

1⁄2 oz (17 μm) and 1 oz (35 μm) electrodeposited or rolled copper foils are most common. 2 oz (70 μm) foils are sometimes used for high current applications.

What is the difference between CuClad 217 and CuClad 250?

CuClad 217 uses a ceramic filled PTFE composite as the dielectric layer, while CuClad 250 uses a woven glass reinforced epoxy. CuClad 217 has a lower dielectric constant of 2.17, but CuClad 250 offers better thermal conductivity and moisture resistance.

Can Rogers CuClad 250 be used at frequencies above 10 GHz?

Yes, with careful PCB layout and design considerations, CuClad 250 can provide stable performance up to millimeter wave frequencies above 30 GHz for certain applications. The dielectric constant remains quite stable over frequency.

What special handling precautions are needed?

CuClad 250 does not require special handling procedures beyond those needed for most high frequency laminates. It should be kept clean and dry and maintained at room temperature for best results.

Conclusion

With its excellent dielectric properties, dimensional stability, thermal conductivity, and ease of processing, Rogers CuClad 250 has become an industry standard high frequency laminate for PCB fabrication. It provides a robust and reliable solution for microwave, high-speed digital, automotive, and other cutting edge electronic applications. Engineers and designers continue to take advantage of CuClad 250’s capabilities in their development of high performance printed circuit boards and electronic circuits.

Leave a Reply