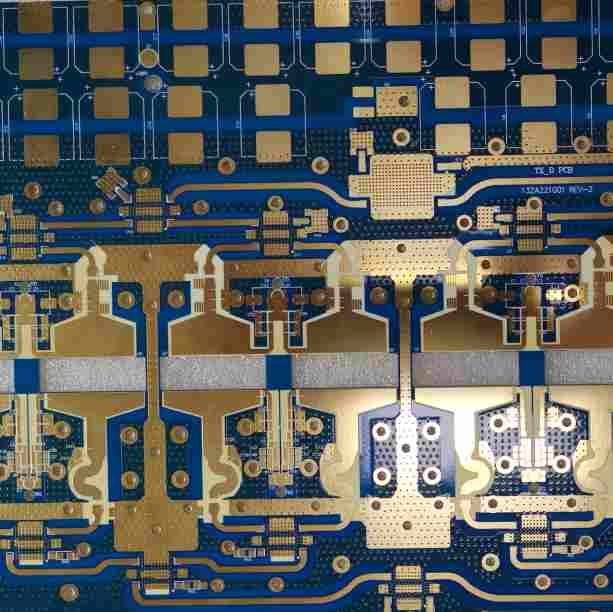

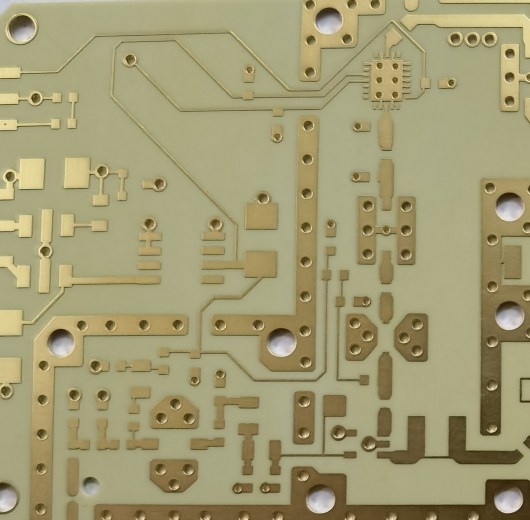

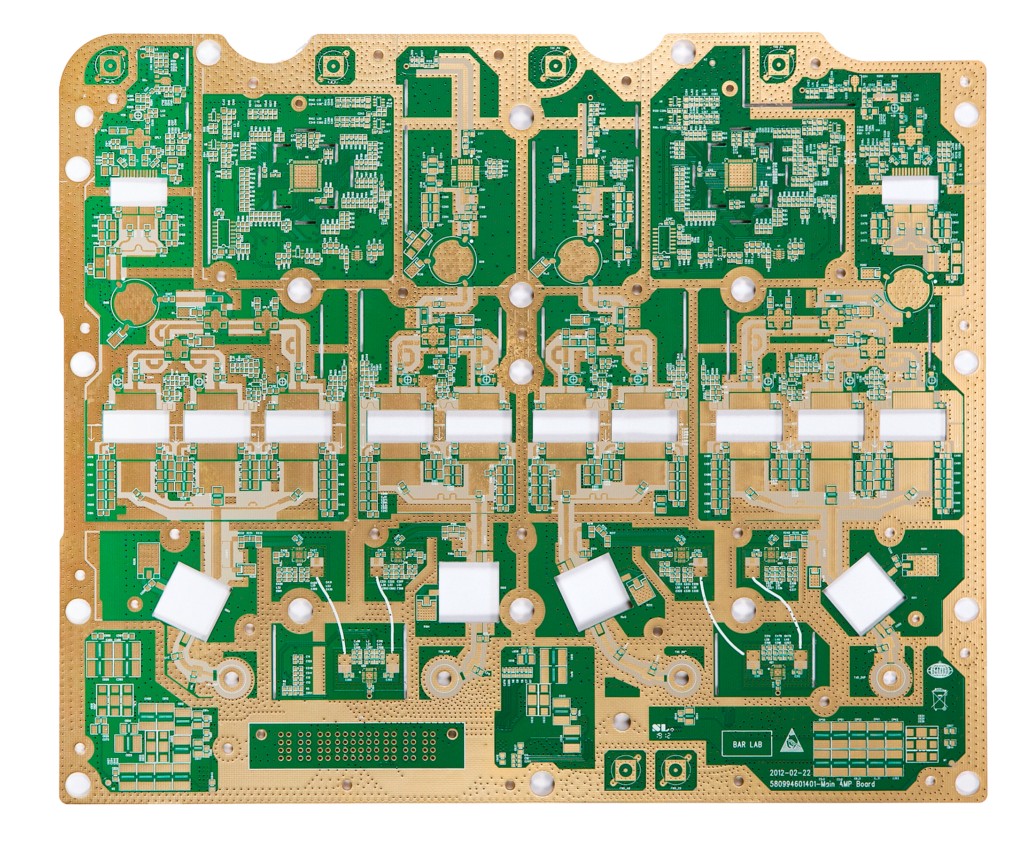

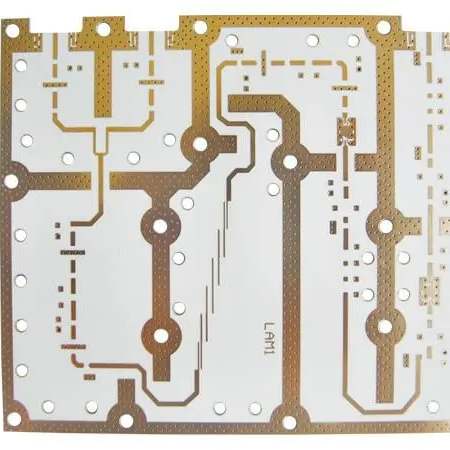

RF PCB

18 Years RF & Microwave Manufacturer

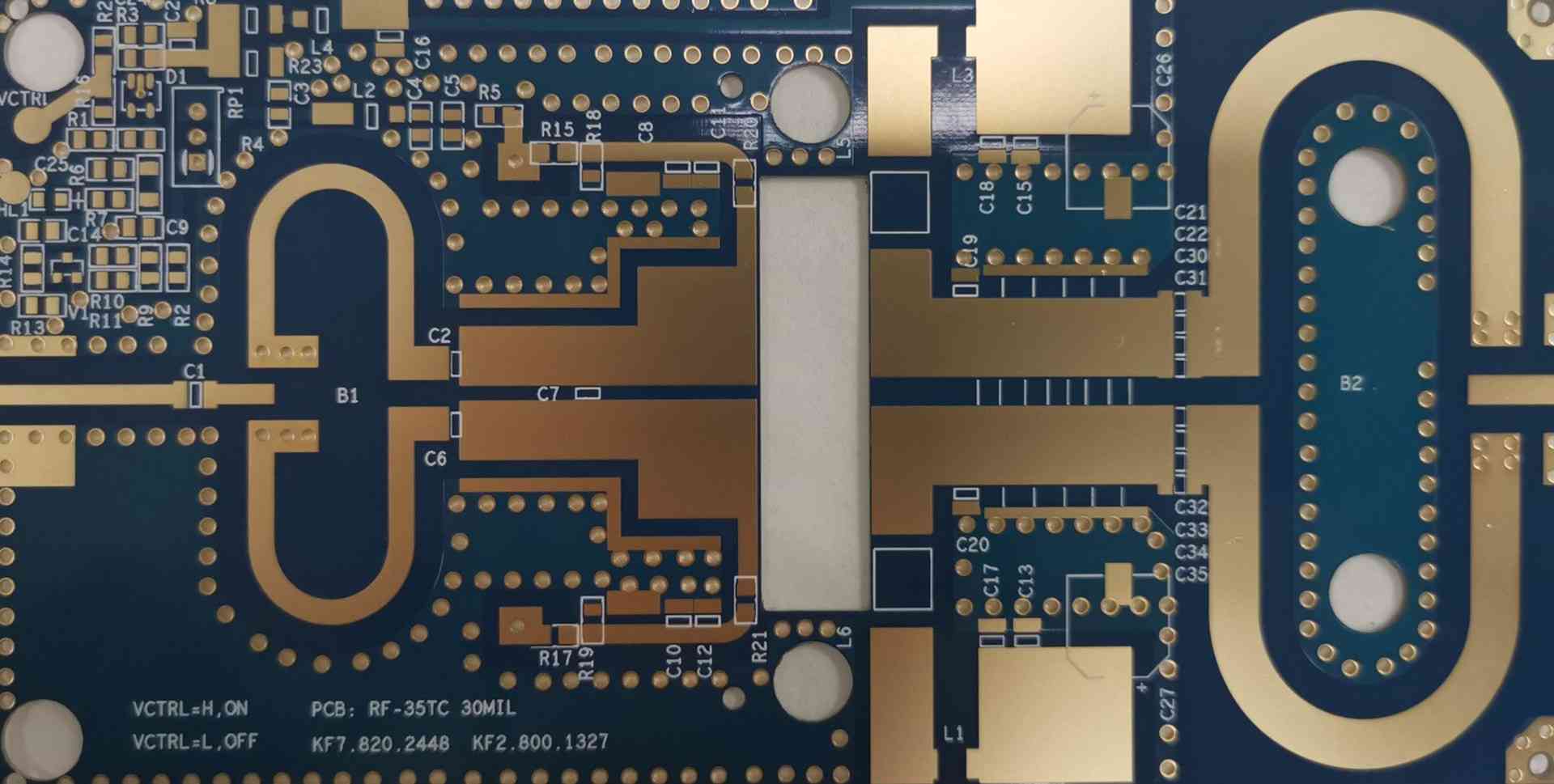

Rogers 4350b 4003c 3003 5880 5870 material PCB Manufacturing

99.8%

Client retention

100% satisfy clients in our work

15+

Years of experience

Fully focused on Rogers PCB

1000+

Clients

Solid and responsible technical team

10K+

Project value

99.8% successfully all project done

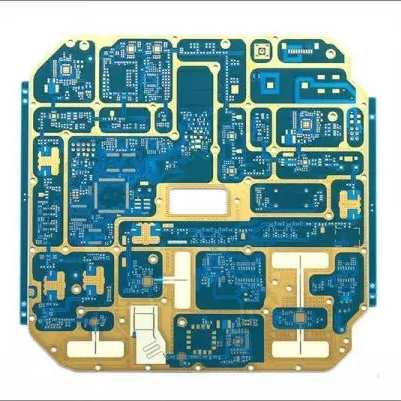

PCB Boards

RF and Microwave Design easy way

PCB Laminates

RF Solutions Laminates and 3D Printable Materials for sale

Rogers RO3000 Series

Rogers RO3000 high frequency circuit materials are ceramic-filled PTFE composites intended for use in commercial microwave and RF applications,This family of advanced laminates offers exceptional electrical and mechanical stability.

Rogers TC Series Laminates

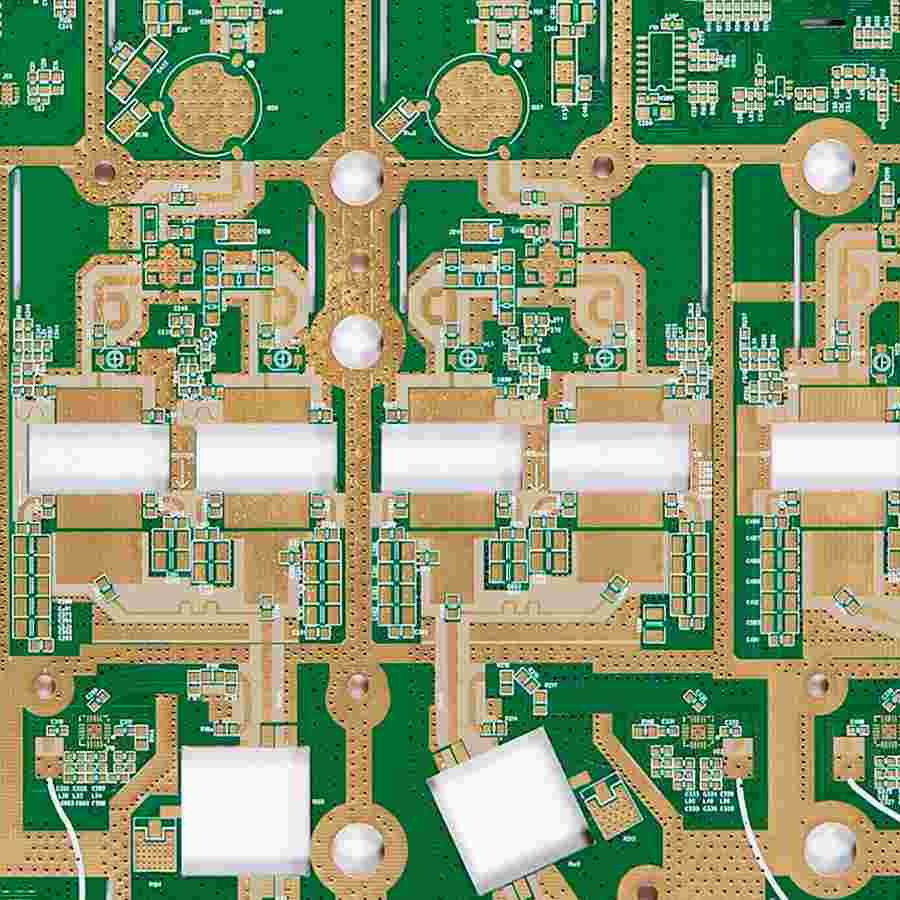

Rogers TC Series laminates are PTFE, woven fiberglass and high thermal conductivity ceramic filled materials that provide improved Printed Circuit Board (PCB) thermal management for applications requiring high power RF signals.

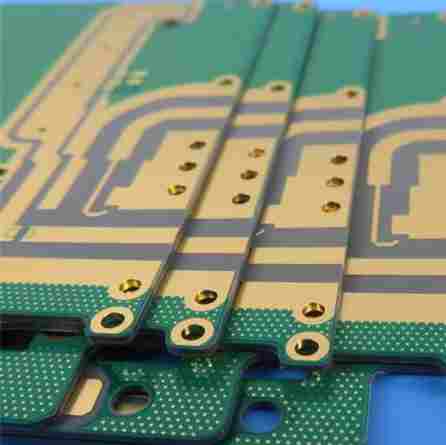

Rogers RO4000 Series

Rogers RO4000 hydrocarbon ceramic laminates and prepregs are the industry leader. Used in microwave and millimeter wave frequencies, this low loss material offers easier use in circuit fabrication and streamlined properties over traditional PTFE materials.

Rogers TMM Laminates

Rogers TMM thermoset microwave laminates and 3D molded shapes combine low thermal coefficient of dielectric constant (Dk), a copper matched coefficient of thermal expansion and dielectric constant uniformity.

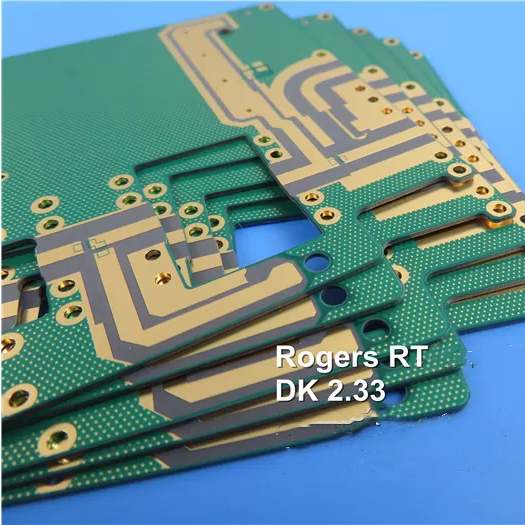

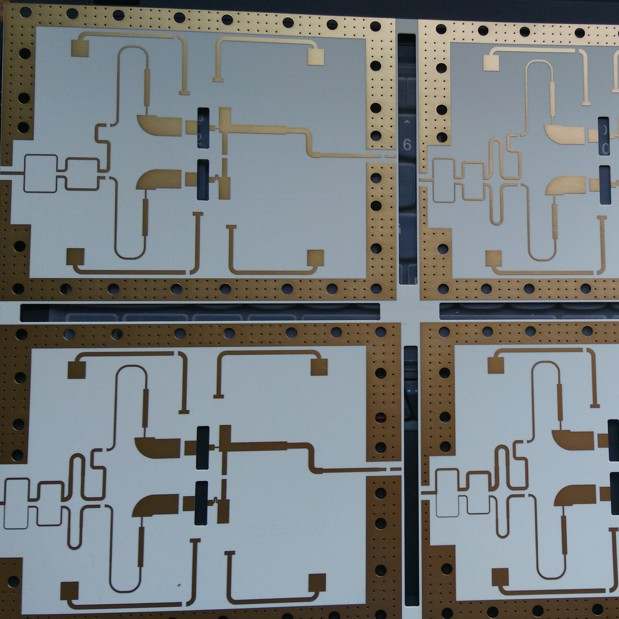

Rogers RT/duroid Laminates

Rogers RT/duroid high frequency circuit materials are filled PTFE (random glass or ceramic) composite laminates for use in high reliability, aerospace and defense applications. The RT/duroid series has a long industry presence of providing high reliability materials with superior performance.

Rogers AD Series Laminates

Rogers AD Series PTFE/woven glass based laminates are designed to deliver the consistent, high performance required of high frequency PCB materials for cost sensitive commercial applications.

PCB Material series

AD Series,Anteo,CLTE Series,CuClad,DiClad,IM Series,IsoClad,Kappa,MAGTREX,Radix,RO3000,RO4000,RT/duroid,TC Series,TMM,XtremeSpeed

CuClad Series Laminates

Rogers CuClad laminates are woven fiberglass reinforced PTFE based composites for use as PCB substrates and radomes in high frequency applications. CuClad laminates feature low dielectric constants (Dk) ranging from 2.17 to 2.60, low electrical loss of tan δ from 0.0009 to 0.0018 at X-band and low moisture absorption. These balanced, cross plied constructed laminates are available up to 36” x 48” in size.

Anteo Laminates

Anteo laminates provide dielectric constants (Dk) in alignment with FR-4 industry standards, simplifying the transition from existing FR-4 designs when superior electrical performance is required.

CLTE Series Laminates

Rogers CLTE Series materials offer tight dielectric constant and thickness tolerance, low loss tangent, low out-gassing and low insertion loss. The ceramic, PTFE woven-glass composite material has higher thermal conductivity than conventional PCB dielectrics and is ideal for thin multi-layer boards, providing the option of the highest degree of embedded resistor consistency in the industry.

DiClad Series Laminates

Rogers DiClad Series laminates are fiberglass reinforced PTFE based composites for use as printed circuit board substrates in high frequency applications. The controlled fiberglass and PTFE content ratio enable DiClad laminates to offer a range of low dielectric constant (Dk) values. Higher PTFE content provides a lower Dk and loss tangent, while higher fiberglass content provides better dimensional stability and registration.

CuClad Series Laminates

Rogers CuClad laminates are woven fiberglass reinforced PTFE based composites for use as PCB substrates and radomes in high frequency applications. CuClad laminates feature low dielectric constants (Dk) ranging from 2.17 to 2.60, low electrical loss of tan δ from 0.0009 to 0.0018 at X-band and low moisture absorption. These balanced, cross plied constructed laminates are available up to 36” x 48” in size.

IM Series Laminates

Rogers IM Series™ laminates include the IM cladding solution of an ultra-smooth electrodeposited copper foil cladding option which has excellent adhesion to the substrate materials. These laminates consist of a PTFE resin system and are woven glass reinforced for excellent dimensional stability.

Who We Are

We’re RogersPCB Manufacturer

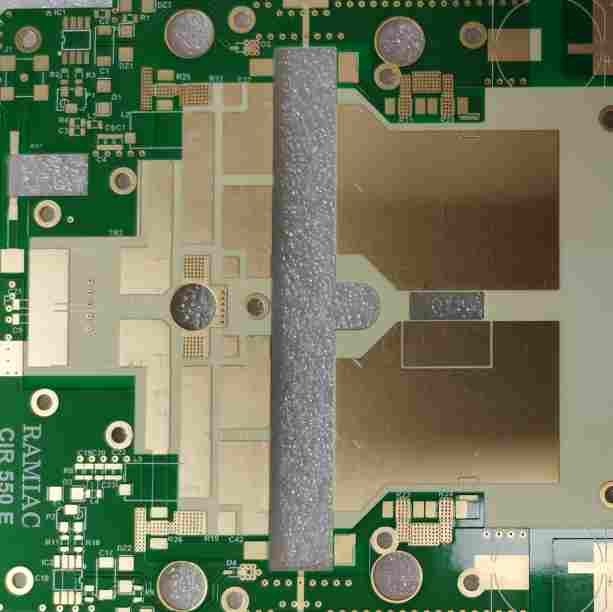

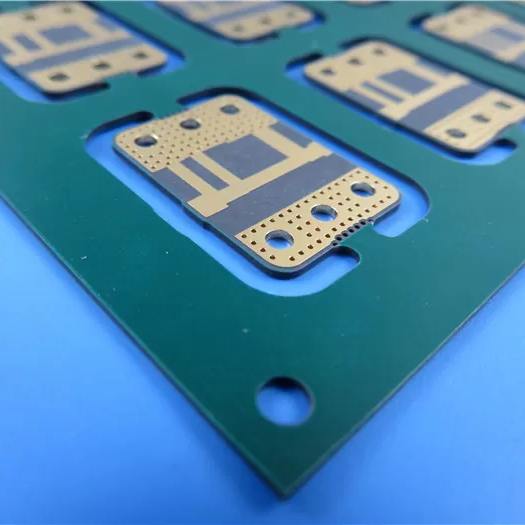

RayMing always has all the thickness and specifications of RO4003C, RO3003C, RO4350B, RO5880, RO5870, and RO4450F prepregs, which can meet your immediate response needs. We have rich experience in RFID data process engineering and a complete high-frequency material processing control system to ensure product design functions.

- High Frequency Device

- Advanced Electronics Solutions

- Elastomeric Material Solutions

What We Do

Specialized Expertise

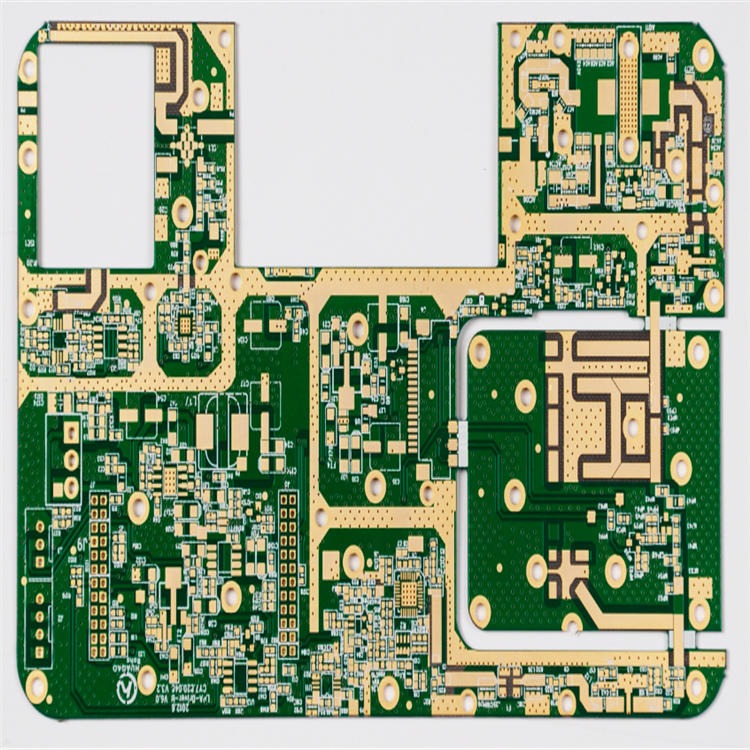

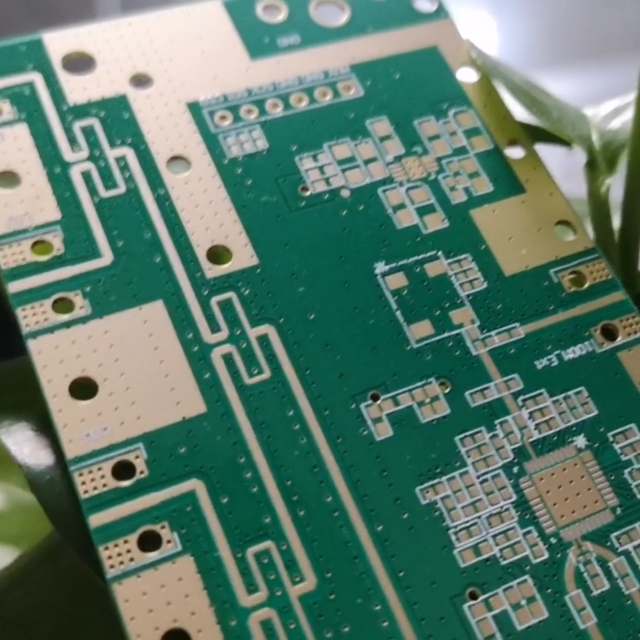

Manufacturing high quality Rogers printed circuit board, Helping electronics engineers achieve better product performance

- Good raw material

- Best equipments

- High Quality Control

18 Years Professional Rogers PCB Manufacturer

Rogers PCB materials is an agile and reliable partner, progressing in line with rapid technology development. Our advanced materials serve customer needs for a wide range of industries. Explore the markets we serve and applications of our products.

Clients Testimonials

WHAT CLIENTS SAY ABOUT US

Sebastian River

High QUALITY ROGERS Board

Antwan Smith

Price good,qUALITY GOOD

Crystal Williams

100% rECOMMEND

Rendell Bradley

FAST ,THANKS

From Our Blog Posts

All about RogersPCB and Rogers Materials

-

How to Select Material for Your PCBs from Cost and Reliability Considerations

Introduction Printed Circuit Boards (PCBs) are the backbone of modern electronic devices, providing the necessary electrical connections and mechanical support for components. The choice of materials used in PCB fabrication plays a critical role in determining the performance, reliability, and cost of the final product. Selecting the right materials involves […]

-

Problems of EMC Technology Application in PCB Design of Electronic Devices and the Strategies

Introduction Electromagnetic Compatibility (EMC) is a critical consideration in the design and development of electronic devices. EMC ensures that electronic devices can operate effectively in their intended environment without causing or suffering from electromagnetic interference (EMI). With the increasing complexity and miniaturization of electronic devices, achieving EMC compliance has become […]

-

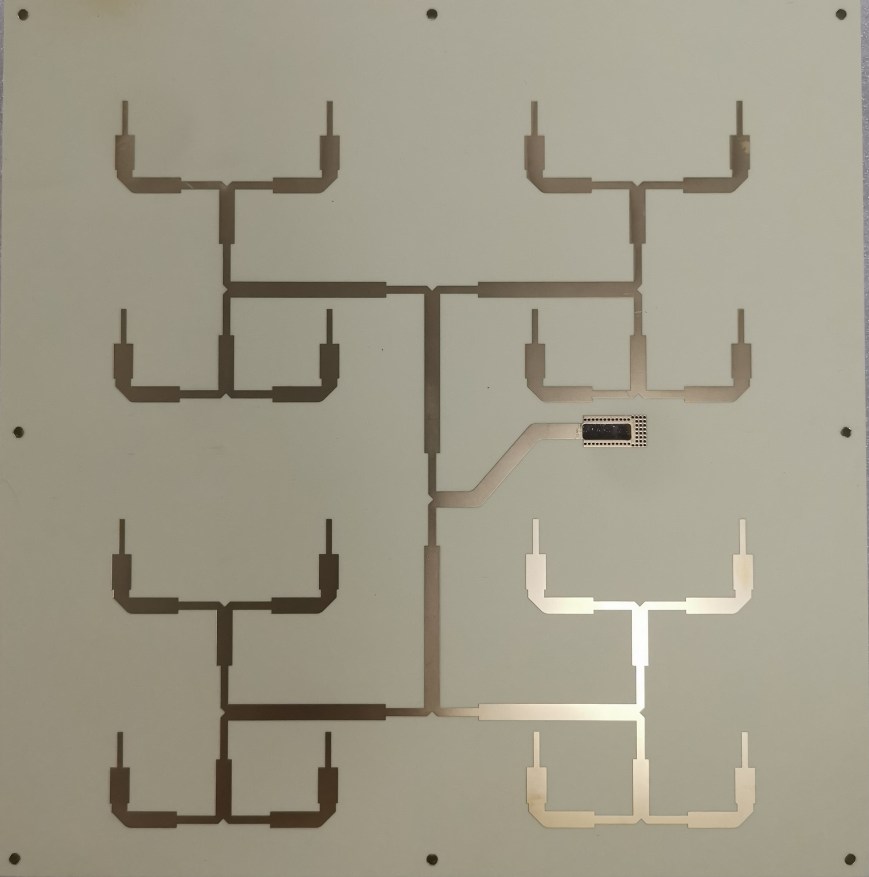

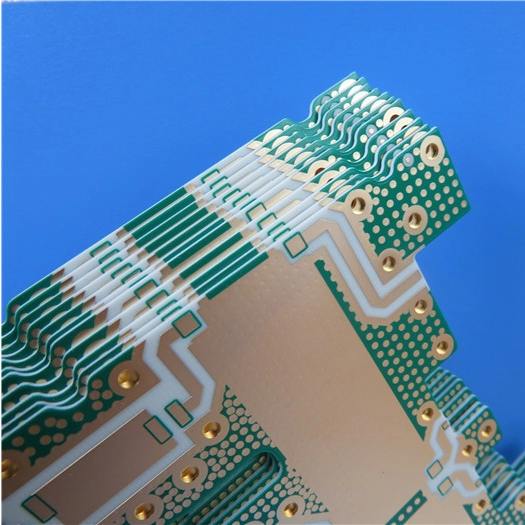

Fabrication Technology on Flex-Rigid PCB Window

Introduction Flex-rigid PCBs, a hybrid of flexible and rigid printed circuit boards, have become increasingly popular in modern electronics due to their ability to combine the benefits of both technologies. These boards are widely used in applications where space constraints, weight reduction, and reliability are critical, such as in aerospace, […]

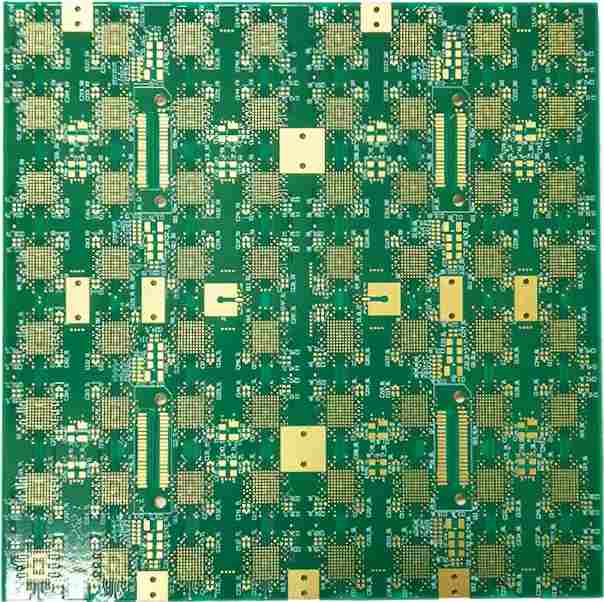

100%

High Quality Guaranteed

100+

RF Materials

1,000+

Global Customers

6,000+

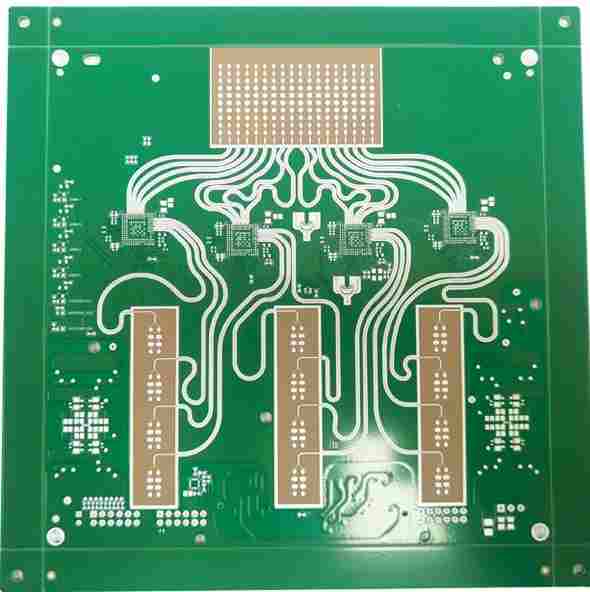

Microwave Projects

Explore More RF Solutions

When reliability, efficiency and performance are critical, design engineers partner with Rogers board to develop and deliver the material technologies they require.

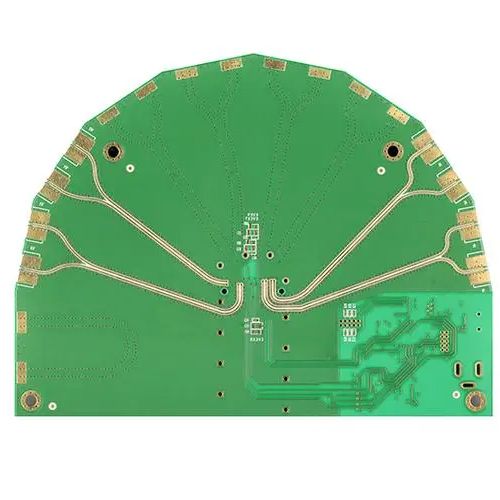

Aerospace & Defense

Advanced materials with high reliability under extreme conditions, critical for aerospace, commercial aircraft and defense applications.

Footwear Design

Rogers PCB is a leader in providing footwear comfort solutions to brands with versatile cushioning technologies. Our solutions add long-lasting performance and comfort to footwear while enabling lighter, stronger and more flexible designs. The proven technology innovator and trusted global partner to leading footwear brands, Rogers focuses on sustainability through all aspects of production, supply chain, product offering and more.

Wired Infrastructure

High frequency materials with quality electrical properties for applications requiring fast performance and data flow.

Automotive & EV/HEV

Rogers pcb is a leading automotive and electric vehicle / hybrid electric vehicle advanced materials supplier with a wide range of industry solutions to power, protect and connect vehicles.

Medical Electronics

Rogers PCB enables high quality patient care in applications including supply transport, medical instruments, patient cushioning and wound care.Advances in medical technology never stop, and neither does Rogers as we continually innovate our materials to enable the latest medical applications.

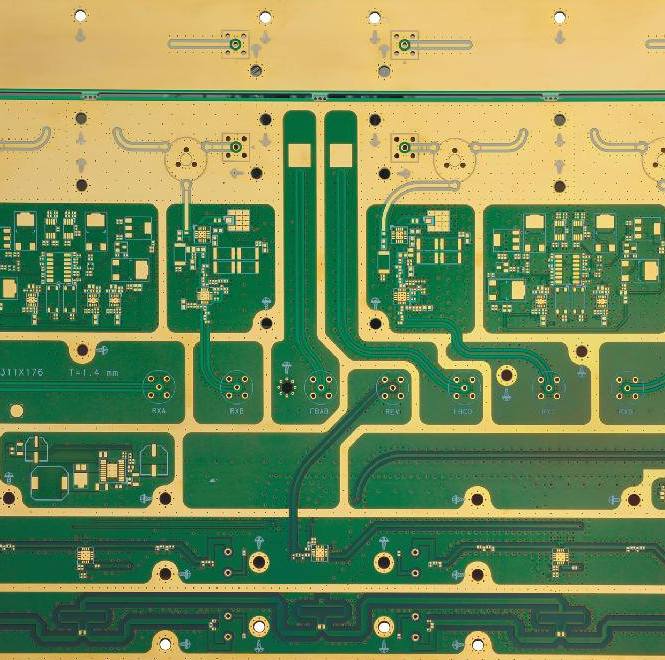

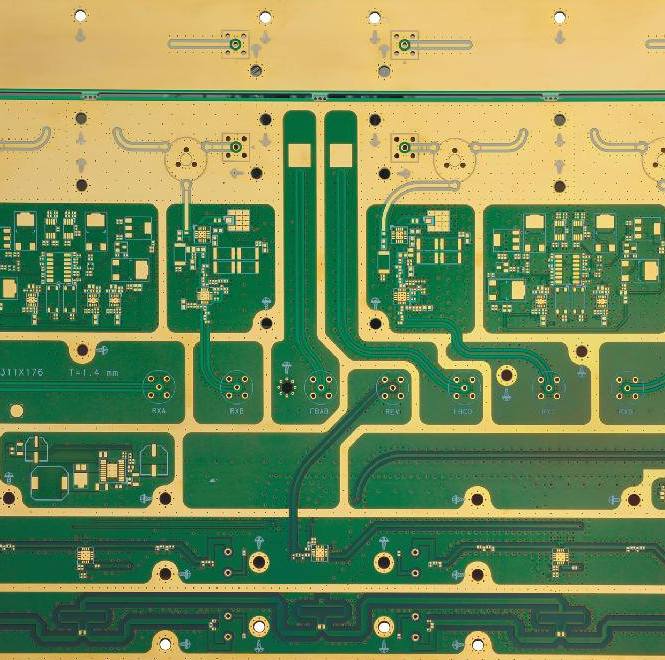

Wireless Infrastructure

Low-loss, high frequency materials with well-controlled dielectric properties to enable microwave and RF applications, including mobile networks.

Connected Devices

Enabling electronic devices and more to operate interactively or autonomously by use of wireless protocols.

Portable Electronics

Rogers pcb provides complex and compact electronics with superior fabrication and protection. Portable devices continue to get smaller, more powerful and more versatile. With every design change, it becomes tougher to fit molded enclosures and hardware to protect sensitive electronics, such as displays and batteries.

Wind & Solar

Increased system efficiency and overall reliability for wind and solar renewable energy sources.

Helping Power, Protect, Connect Our World

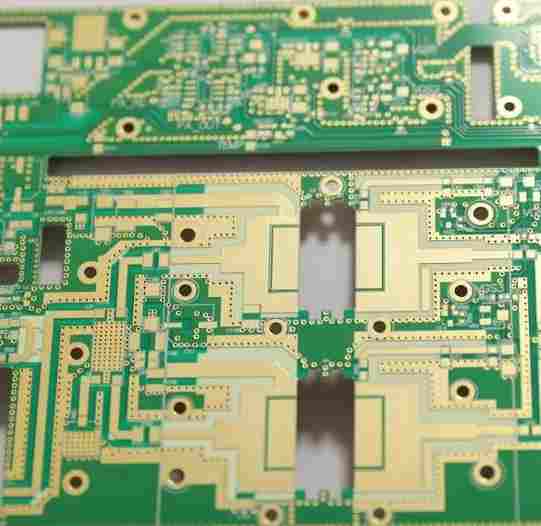

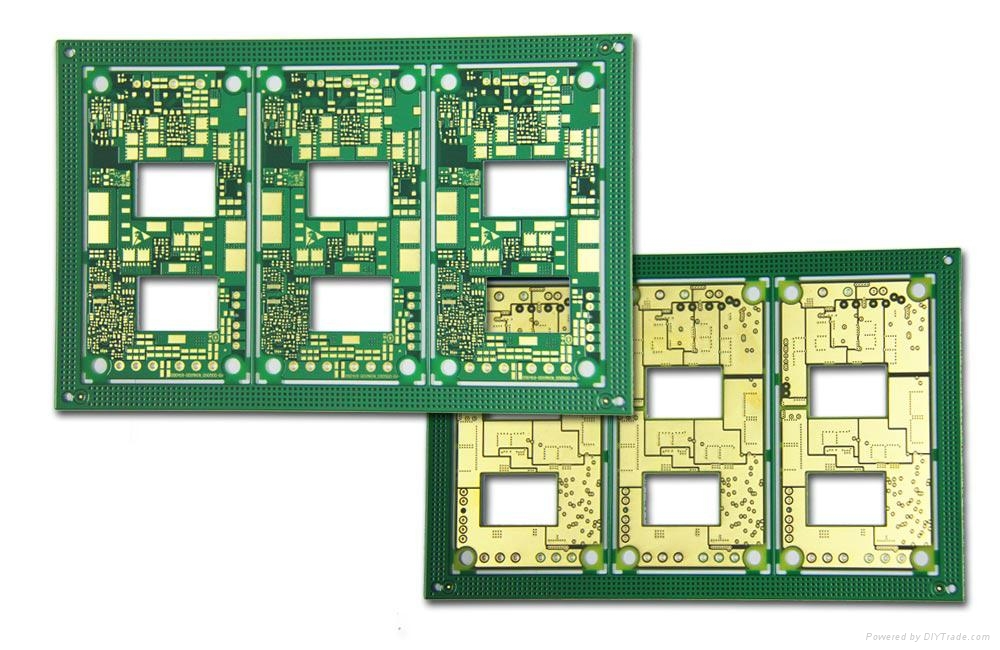

Rogers 4350b + Fr4

Ro4350b Hybrid PCB

Rogers 4003C hybrid Fr4 PCB

Multi-Press Board

Rogers 3003+ IT180A

6Layer RO3003 +TG170