Introduction to Rogers Kappa 438

Rogers Kappa 438 is an engineered thermoplastic laminate material designed for reliability and high performance in advanced printed circuit boards (PCBs). With a low dissipation factor and tight dielectric constant tolerance, it provides consistent electrical performance through microwave frequencies.

Key features of Rogers Kappa 438 include:

- Stable dielectric constant of 3.38 ± 0.05

- Low loss for high frequency efficiency

- Low moisture absorption compared to thermosets

- Lead-free compatible with high TG > 280°C

- Halogen-free material for environmental compliance

- RoHS and REACH compliant

The precision dielectric properties make Rogers Kappa 438 an ideal choice for microwave circuits and other high-speed digital or RF applications.

Rogers Kappa 438 Material Properties

Rogers Kappa 438 possesses a unique set of properties well-suited for controlled impedance microwave PCBs:

Stable Dielectric Constant

- Dielectric constant of 3.38 ± 0.05

- Stable across a wide frequency range

- Allows tight impedance control

Low Loss Tangent

- Loss tangent of 0.0026 at 10 GHz

- Excellent loss characteristics for optimized signal integrity

Low Moisture Absorption

- 0.06% moisture absorption

- Minimal impact on dielectric constant

High Glass Transition Temperature

- TG of 280°C

- Allows lead-free assembly temperatures

Halogen Free Material

- Halogen-free for reduced environmental impact

- Meets ROHS and REACH requirements

Key Material Properties Summary

| Property | Value |

|---|---|

| Dielectric Constant | 3.38 ± 0.05 |

| Loss Tangent | 0.0026 at 10 GHz |

| Moisture Absorption | 0.06% |

| TG | 280°C |

| Halogen Content | Halogen Free |

Rogers Kappa 438 Laminate Copper Cladding

Rogers Kappa 438 materials are clad with rolled annealed copper foil on one or both sides. Typical foil options include:

- Standard 1⁄2, 1, 2 oz electrodeposited copper foils

- Low profile foils for high frequency applications

- Heavier weights up to 6 oz for high current capacity

- Reverse treat and bond-ply foils for enhanced adhesion

The copper foil properties impact loss, current capacity, thermal performance, and reliability.

PCB Design with Rogers Kappa 438

Rogers Kappa 438 enables the design of reliable high frequency PCBs when following sound design practices:

Controlled Impedances

- Match trace impedances to system characteristic impedance

- Account for material dielectric tolerance

- Simulate over required bandwidth

Minimize Conductor Losses

- Use thicker copper weights where allowed

- Minimize vias and employ backdrilling

- Specify low roughness foil

Thermal Management

- Ensure sufficient thermal vias for heat dissipation

- Incorporate backside cooling features if needed

- Avoid high thermal gradients

Signal Integrity

- Use proper component spacing and isolation

- Treat impedance discontinuities

- Model to reveal resonances

Tested prototypes validate performance prior to committing to full production.

PCB Fabrication with Rogers Kappa 438

Rogers Kappa 438 laminates can be fabricated into circuits using standard PCB processes:

Imaging and Etching

- Compatible with most liquid photoresists

- Can be etched in cupric chloride or ammoniacal etchants

Hole Drilling

- Use mechanical or laser drilling

- Plasma etching available for fine features

Plating and Lamination

- Electroless copper and direct metallization plating

- Bond with prepregs or adhesive films

Final Finishes

- ENIG, immersion silver, immersion tin, OSP compatible

- Special plating processes may be required

Rogers provides additional guidelines to ensure optimal fabrication results.

Rogers Kappa 438 Material Availability

Rogers Kappa 438 laminates are available under the RO4835TM product designation with standard offerings that include:

| Material | Description |

|---|---|

| RO4835 (5) | 0.005” (0.127mm) dielectric |

| RO4835 (10) | 0.010” (0.254mm) dielectric |

| RO4835 (20) | 0.020” (0.508mm) dielectric |

| RO4835 (30) | 0.030” (0.762mm) dielectric |

| RO4835 (40) | 0.040” (1.016mm) dielectric |

- Sheet sizes up to 18” x 24”

- Prepregs available for multilayer designs

- Custom dielectrics, foils, and panel sizes

Rogers Kappa 438 Laminate Applications

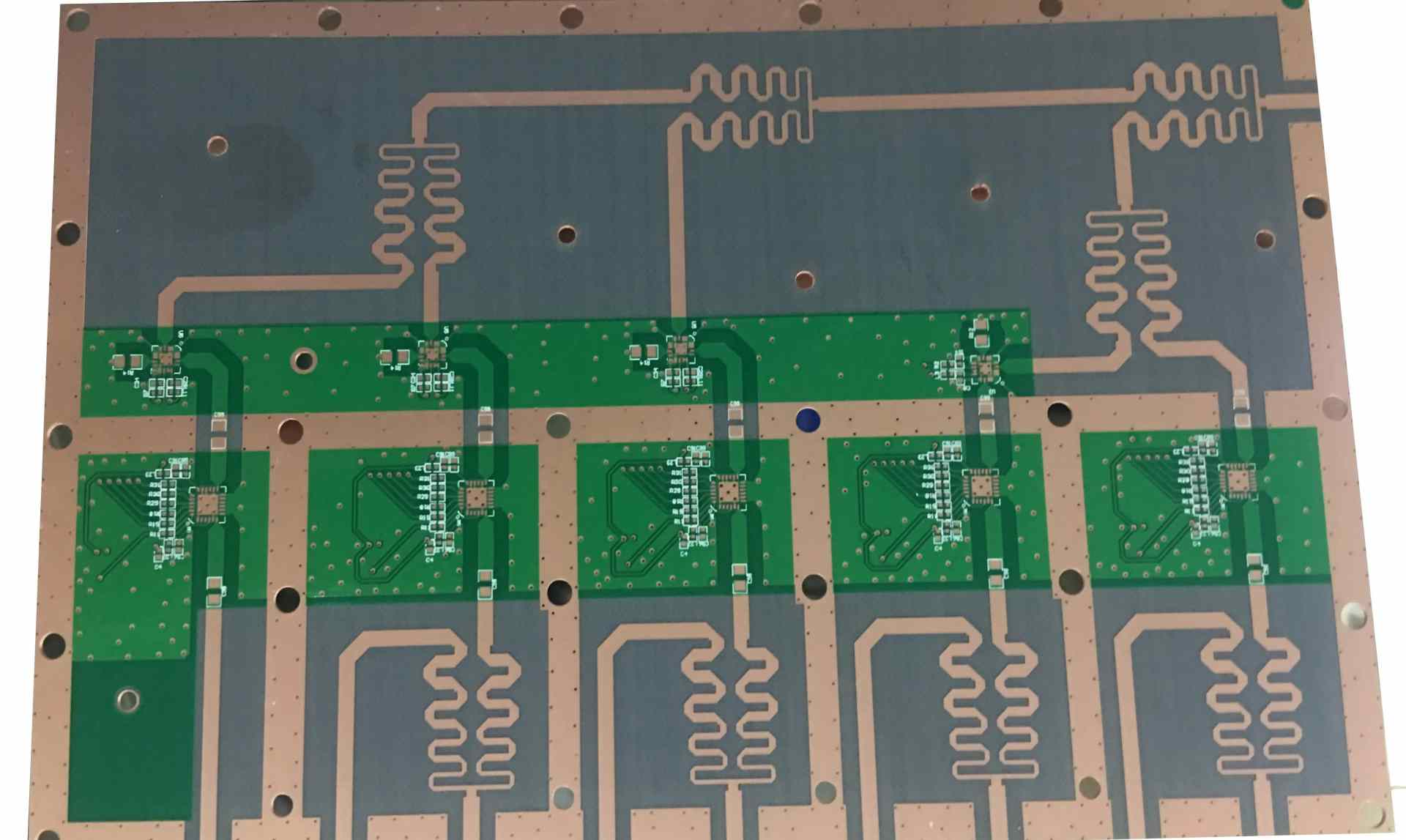

The stable dielectric properties make Rogers Kappa 438 suitable for a variety of microwave and high speed digital applications:

Test and Measurement

- Oscilloscope and network analyzer PCBs

- Test fixtures and calibration boards

- ATE interfaces

Aerospace and Defense

- Phased array radars

- Electronic warfare circuit boards

- Communications payloads

Wireless Infrastructure

- 5G NR radio boards

- Microwave backhaul links

- Wireless base stations

Automotive Electronics

- Radar and LIDAR circuits

- Vehicle infotainment modules

- ADAS sensor PCBs

High Speed Digital

- Data processing boards

- High speed serial interfaces

- Low-loss power distribution

Considerations for Rogers Kappa 438 Material

While providing electrical and reliability advantages, some factors to consider when selecting Rogers Kappa 438 include:

- Higher cost than standard FR-4 laminates

- Processing may require additional controls

- Lead times typically longer than standard materials

- Susceptible to thermal stresses and shrinkage

- Not compatible with pressing and wave soldering

For microwave and other high performance PCBs, Rogers Kappa 438 is often the material of choice to achieve the stringent electrical and reliability requirements.

Frequently Asked Questions

What is the melting point of Rogers Kappa 438 material?

Rogers Kappa 438 has a melting point of 315°C. This high melting temperature contributes to excellent thermal stability for lead-free assembly processes.

What types of prepregs can be used with Rogers Kappa 438 laminates?

Rogers offers UV-stabilized thermoset prepregs such as RO4450BTM and RO4450FTM which are compatible for multilayer circuits using Kappa 438 cores. Thermosetting bondplys provide reliable adhesion and dielectric properties.

Does Rogers Kappa 438 require special chemical solutions for PCB processing?

Standard chemical solutions used for most laminates are compatible with Rogers Kappa 438. This includes ammoniacal etchants, acid copper plating, alkaline developing, and solder masks. Special pretreatments may be needed for plating or bonding.

What is the CTE of Rogers Kappa 438 in the Z direction?

The coefficient of thermal expansion (CTE) of Rogers Kappa 438 in the Z direction is 50 ppm/°C. This value is well matched to the 13 ppm/°C CTE in the X and Y directions.

Is Rogers Kappa 438 material RoHS compliant?

Yes, Rogers Kappa 438 is a halogen-free, lead-free material that is fully compliant with RoHS and REACH requirements for hazardous substances. This makes it suitable for electronics needing to meet environmental regulations.

Leave a Reply