An Introduction to PORON V-0 Foam

PORON V-0 foam is a type of closed-cell polyurethane foam that is designed to meet various flammability standards. The “V-0” designation indicates that the foam has met the UL 94 flammability standard with the highest rating. This means that the foam self-extinguishes within 10 seconds after removal of an ignition source, and does not produce any flaming drips.

PORON V-0 is an engineered foam that provides protection against fire and extreme heat while maintaining excellent cushioning properties. Some of the key benefits of PORON V-0 foam include:

Fire Resistance

<table> <thead> <tr> <th>Flammability Standard</th> <th>PORON V-0 Rating</th> </tr> </thead> <tbody> <tr> <td>UL 94</td> <td>V-0</td> </tr> <tr> <td>FMVSS 302</td> <td>Passes</td> </tr> <tr> <td>DIN 75200</td> <td>Passes</td> </tr> </tbody> </table>

Cushioning and Shock Absorption

PORON V-0 foam provides excellent impact absorption and vibration dampening, making it ideal for cushioning in helmets, athletic gear, electronics cases, and more. The foam’s open-cell structure allows for energy absorption upon impact.

Lightweight

This foam is very lightweight, with a typical density range of 0.20-0.40 g/cm3. The lightweight nature makes it suitable for applications where minimal weight is important.

Customizable

PORON V-0 foam can be die cut into various shapes and thicknesses to meet specific application requirements. The foam is also available in a wide range of colors.

Compression Set Resistance

The foam exhibits low compression set, meaning it retains its original thickness after compression. This resiliency is important for long-term cushioning performance.

Applications of PORON V-0 Foam

PORON V-0 foam has many uses across a diverse set of industries where fire resistance, cushioning, and lightweight are critical factors. Some examples include:

- Aviation and aerospace – aircraft and helicopter seat cushions, headrests, armrests

- Military – hard armor padding, helmet liners

- Automotive – headliners, seating

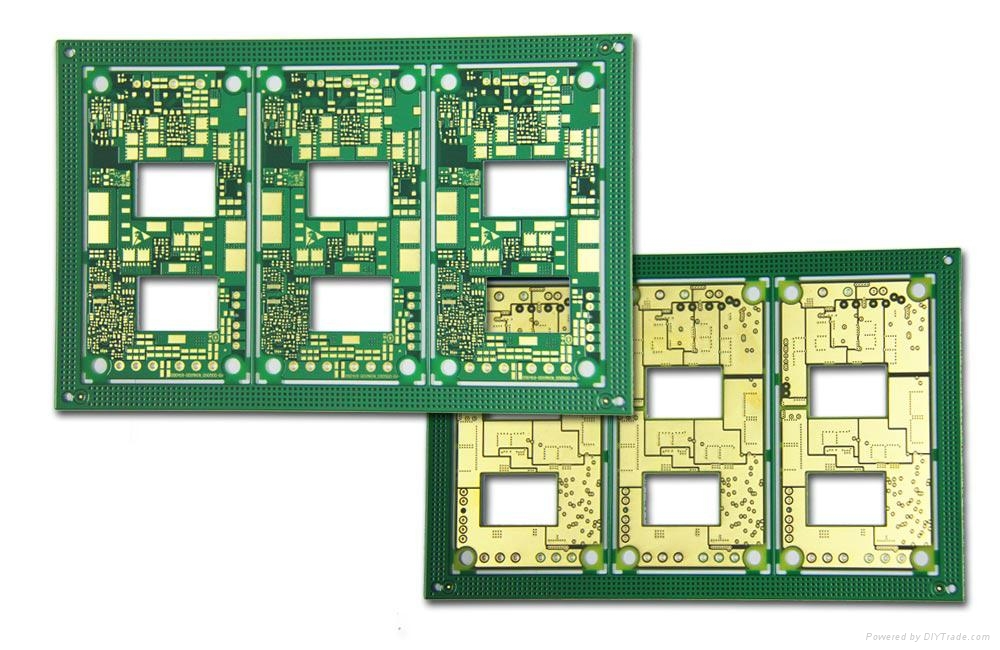

- Electronics – cases and padding for devices

- Industrial safety – hard hat liners and suspension systems

The foam is often die cut into specific shapes for these applications. For example, formed pads for knee protection in military uniforms, or custom-shaped inserts for electronics cases.

Sourcing PORON V-0 Foam

PORON V-0 is manufactured by Rogers Corporation, a leading foam materials company. Rogers offers several grades of PORON V-0 to accommodate different requirements:

- PORON 4701-30-15%VF: The standard grade with optimum cushioning. 15% vinyl content.

- PORON 4701-50-20%VF: Higher resiliency and tear strength. 20% vinyl content.

- PORON RP-50-20%VF: Super soft with latex-like feel. 20% vinyl content.

PORON V-0 is available from various authorized distributors globally. When sourcing this foam, customers should check that the distributor is authorized by Rogers Corporation to ensure getting the genuine product. Some key considerations when selecting a distributor include:

- Technical expertise with PORON foams

- Capability to die cut, laminate, and fabricate finished parts

- Stocking distributor to enable quick delivery

- Competitive pricing and capabilities for low minimum orders

Conclusion

With its unique combination of flammability compliance, cushioning properties, and lightweight nature, PORON V-0 foam is an essential material for many protective and cushioning applications. This engineered foam enables next-generation product designs in aviation, military, automotive, electronics, and beyond. By selecting a knowledgeable authorized distributor, product designers can easily source this material and tap into its benefits.

Frequently Asked Questions

What are some key property tests conducted on PORON V-0 foam?

Some standard tests include density, tensile strength, elongation, tear strength, compression set, and compression force deflection. These tests help characterize the foam’s properties. Flammability tests like UL 94 V-0, FMVSS 302, and DIN 75200 are critical for qualifying the fire resistance.

Does PORON V-0 foam contain fire retardant chemical additives?

No, PORON V-0 meets flammability standards without the use of chemical fire retardant additives. It is inherently flame resistant due to the foam’s cell structure and base chemistry.

Is the foam affected by water or humidity?

PORON foams are closed-cell and resistant to water absorption. This makes the foam retain its properties even in humid environments.

Can PORON V-0 foam be die cut into intricate shapes?

Yes, PORON V-0 can be precision die cut using plotters, lasers, or steel rule dies. This allows creating complex curved, beveled, or contoured shapes to fit unique application requirements.

Does the foam require any special adhesive?

PORON can be bonded with a variety of adhesives including epoxies, urethanes, acrylics, and pressure sensitive adhesives. Rogers Corporation provides technical advice on selecting the right adhesive.

Leave a Reply