Introduction to PCB fabrication

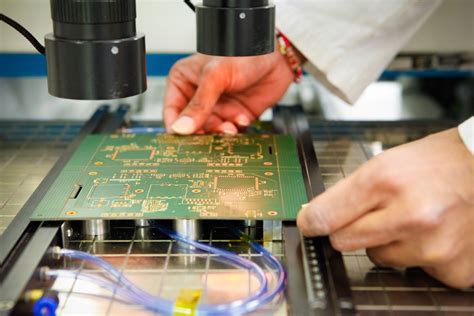

Printed Circuit Board (PCB) fabrication is a crucial process in the electronics industry, enabling the creation of complex circuits on a compact and reliable substrate. With the increasing demand for faster turnaround times and smaller production volumes, companies like RAYPCB have stepped up to offer expedited medium and small volume PCB fabrication services with lead times as short as 72 hours.

What is PCB Fabrication?

PCB fabrication is the process of creating a printed circuit board, which is a flat board made of insulating materials with conductive pathways etched onto its surface. These pathways, also known as traces, connect various electronic components to form a functional circuit. PCBs are used in a wide range of applications, from consumer electronics to aerospace and medical devices.

The PCB Fabrication Process

The PCB fabrication process typically involves the following steps:

- Design: The circuit is designed using specialized software, such as EDA (Electronic Design Automation) tools.

- Printing: The design is printed onto a transparent film or directly onto the copper-clad laminate using a photoplotter or direct imaging machine.

- Etching: The exposed copper is etched away, leaving only the desired traces.

- Drilling: Holes are drilled into the board to accommodate through-hole components and vias.

- Plating: The holes are plated with copper to ensure electrical connectivity between layers.

- Solder Mask Application: A protective layer, called solder mask, is applied to the board to insulate the traces and prevent short circuits.

- Silkscreen: Text and symbols are printed onto the board for component identification and assembly instructions.

- Surface Finish: A surface finish, such as HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), or OSP (Organic Solderability Preservative), is applied to protect the exposed copper and enhance solderability.

- Electrical Testing: The board undergoes electrical testing to ensure its functionality and adherence to the design specifications.

RAYPCB’s Expedited Medium and Small Volume PCB Fabrication Service

RAYPCB, a leading PCB manufacturing company, offers expedited medium and small volume PCB fabrication services with an impressive 72-hour lead time. This service caters to customers who require quick turnaround times for prototyping, testing, or small-scale production.

Benefits of RAYPCB’s Expedited PCB Fabrication Service

- Fast Turnaround: With a 72-hour lead time, RAYPCB ensures that your PCBs are fabricated and delivered quickly, enabling faster time-to-market for your products.

- High Quality: Despite the expedited process, RAYPCB maintains strict quality control standards, ensuring that your PCBs meet the highest industry standards.

- Cost-effective: RAYPCB’s expedited service is competitively priced, making it an affordable option for medium and small volume production runs.

- Flexibility: RAYPCB accommodates a wide range of PCB specifications, including different materials, layer counts, and surface finishes.

PCB Specifications Supported by RAYPCB

| Specification | Range |

|---|---|

| PCB Layers | 1-16 |

| PCB Thickness | 0.4mm – 3.2mm |

| Copper Weight | 0.5oz – 6oz |

| Minimum Hole Size | 0.2mm |

| Minimum Line Width/Spacing | 3mil/3mil |

| Solder Mask Color | Green, Red, Yellow, Blue, White, Black |

| Surface Finish | HASL, ENIG, OSP, Immersion Silver, Immersion Tin |

Advantages of Medium and Small Volume PCB Fabrication

Medium and small volume PCB fabrication offers several advantages over large-scale production runs:

- Faster Iteration: Smaller production runs allow for quicker design iterations and improvements, as you can test and refine your PCBs without committing to a large inventory.

- Lower Upfront Costs: With smaller volumes, the initial investment in PCB fabrication is lower, making it more accessible for startups, small businesses, and individual designers.

- Reduced Inventory Risk: Producing PCBs in smaller quantities reduces the risk of holding excess inventory, which can become obsolete or tie up valuable resources.

- Customization: Medium and small volume fabrication allows for greater customization options, as you can easily modify your PCB design without incurring significant costs.

FAQ

1. What is the minimum order quantity for RAYPCB’s expedited PCB fabrication service?

RAYPCB’s expedited PCB fabrication service caters to medium and small volume production runs, with a minimum order quantity of 5 pieces.

2. How long does it take to receive my PCBs after placing an order?

With RAYPCB’s expedited service, you can expect to receive your PCBs within 72 hours of placing your order, subject to design approval and payment confirmation.

3. What file formats does RAYPCB accept for PCB designs?

RAYPCB accepts PCB design files in the following formats: Gerber RS-274X, ODB++, and PCB design software native formats (such as Altium Designer, Eagle, and KiCad).

4. Does RAYPCB offer assembly services for the PCBs they manufacture?

Yes, RAYPCB offers PCB Assembly services, including SMT (Surface Mount Technology) and through-hole assembly. You can request a quote for assembly services along with your PCB fabrication order.

5. What quality control measures does RAYPCB employ to ensure the reliability of their PCBs?

RAYPCB follows strict quality control procedures, including:

– 100% electrical testing of all PCBs

– Automated optical inspection (AOI) to detect surface defects

– Cross-section analysis to verify the PCB structure and layer integrity

– Impedance testing for Controlled impedance PCBs

– Final visual inspection before packaging and shipping

Conclusion

RAYPCB’s expedited medium and small volume PCB fabrication service, with its 72-hour lead time, offers a fast and reliable solution for companies and individuals in need of quick PCB Prototyping and production. By leveraging the advantages of smaller production runs, such as faster iteration, lower upfront costs, and reduced inventory risk, you can optimize your PCB design and manufacturing process. With RAYPCB’s commitment to quality and customer satisfaction, you can trust that your PCBs will meet the highest industry standards, even with the expedited turnaround time.

Leave a Reply