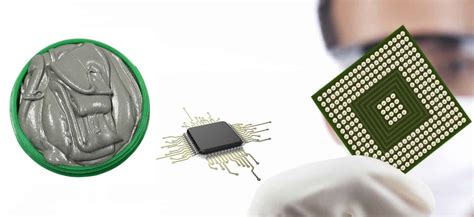

What is Solder Paste?

Solder paste is a mixture of tiny solder particles suspended in flux. It is a crucial component in the process of surface mount technology (SMT) assembly, where electronic components are mounted directly onto the surface of a printed circuit board (PCB). The solder paste is applied to the PCB pads using a stencil, and then the components are placed on top of the paste. When heated, the solder particles melt and form a strong electrical and mechanical bond between the component leads and the PCB pads.

Composition of Solder Paste

Solder paste typically consists of the following ingredients:

- Solder alloy particles (usually tin, lead, and silver)

- Flux (rosin, activators, and solvents)

- Thickening agents

- Additives for improved printing and storage properties

The most common solder alloys used in solder paste are:

| Alloy | Composition | Melting Point (°C) |

|---|---|---|

| Sn63/Pb37 | 63% Tin, 37% Lead | 183 |

| Sn62/Pb36/Ag2 | 62% Tin, 36% Lead, 2% Silver | 179 |

| SAC305 | 96.5% Tin, 3% Silver, 0.5% Copper | 217-220 |

| Sn42/Bi57/Ag1 | 42% Tin, 57% Bismuth, 1% Silver | 138 |

The flux in solder paste serves several important functions:

- Removes oxides from the metal surfaces to ensure good wetting and bonding

- Protects the metal surfaces from oxidation during the soldering process

- Improves the flow and spread of the molten solder

- Helps to transfer heat from the heat source to the joint area

Solder Paste Properties

Viscosity

Viscosity is a measure of a fluid’s resistance to flow. In solder paste, viscosity is a critical property that affects its printability and how well it retains its shape after being dispensed onto the PCB. Solder paste with the correct viscosity will result in a clean, precise print with minimal slumping or spreading.

Factors that influence solder paste viscosity include:

- Particle size and shape

- Flux composition

- Metal content

- Temperature

Slump

Slump refers to the tendency of solder paste to spread or flow after being printed on the PCB. Excessive slump can lead to bridging between adjacent pads or component misalignment. Slump is affected by factors such as viscosity, temperature, and the thickness of the stencil used for printing.

Tack

Tack, or stickiness, is the ability of solder paste to hold components in place after placement. Good tack ensures that components remain in their correct positions during handling and transport to the reflow oven. Tack is influenced by the flux composition and the solids content of the paste.

Shelf Life

Shelf life is the length of time that solder paste can be stored before it begins to degrade in quality. Solder paste shelf life is typically between 3 to 6 months when stored at the recommended temperature (usually between 0-10°C). Proper storage and handling of solder paste are essential for maintaining its performance and reliability.

Solder Paste Application Process

Stencil Printing

Stencil printing is the most common method for applying solder paste to PCBs in SMT assembly. A stencil is a thin metal sheet with apertures that correspond to the PCB pads. The stencil is placed over the PCB, and solder paste is dispensed onto the stencil. A squeegee blade is then used to spread the paste across the stencil, forcing it through the apertures and onto the PCB pads.

Factors that affect the quality of the stencil print include:

- Stencil thickness and aperture size

- Squeegee blade pressure and speed

- Solder paste viscosity and rheology

- PCB and stencil cleanliness

Dispensing

Solder paste dispensing is an alternative method for applying paste to PCBs, particularly for low-volume production or rework. Dispensing involves using a pneumatic or positive displacement pump to apply solder paste directly onto the PCB pads. This method offers greater flexibility and control over the amount of paste applied but is slower and less consistent than stencil printing.

Inspection

After solder paste is applied to the PCB, it is crucial to inspect the print quality to ensure good solder joint formation. Automated solder paste inspection (SPI) systems use 2D or 3D imaging to check for defects such as insufficient or excessive paste volume, bridging, or misalignment. SPI helps identify issues early in the assembly process, reducing the risk of costly rework or failures.

Reflow Soldering

Reflow soldering is the process of heating the solder paste to melt the solder particles and form a permanent bond between the component leads and PCB pads. The reflow process typically involves the following stages:

- Preheat: The PCB is gradually heated to activate the flux and evaporate solvents.

- Thermal soak: The temperature is maintained to allow the components and PCB to reach a uniform temperature.

- Reflow: The temperature is increased above the melting point of the solder alloy, causing the solder to melt and wet the surfaces.

- Cooling: The PCB is cooled to solidify the solder joints.

Proper control of the reflow profile is essential for achieving high-quality solder joints. Factors such as peak temperature, time above liquidus, and cooling rate must be optimized based on the solder paste alloy, PCB design, and component characteristics.

Solder Paste Defects and Troubleshooting

Despite careful process control, solder paste defects can still occur during SMT assembly. Some common defects include:

- Insufficient or excessive solder paste volume

- Solder bridging or shorts

- Poor wetting or non-wetting

- Solder beading or balling

- Voiding

To troubleshoot solder paste defects, consider the following factors:

- Solder paste quality and storage conditions

- Stencil design and cleanliness

- Printing parameters (pressure, speed, separation)

- Reflow profile and oven settings

- PCB and component cleanliness and quality

Regular process monitoring, SPI, and visual inspection can help identify and correct solder paste issues before they lead to more serious problems downstream.

Frequently Asked Questions (FAQ)

-

What is the difference between solder paste and solder wire?

Solder paste is a mixture of fine solder particles suspended in flux, used for surface mount assembly. Solder wire is a solid wire of solder alloy, typically used for through-hole soldering and rework. -

Can solder paste be reused?

No, solder paste should not be reused once it has been printed onto a PCB. Unused paste can be stored in a sealed container for later use, but any paste that has been exposed to air or contamination should be discarded. -

How do I choose the right solder paste for my application?

When selecting a solder paste, consider factors such as the solder alloy composition, particle size, flux type, and viscosity. Consult with your solder paste supplier or manufacturer for recommendations based on your specific PCB design, components, and process requirements. -

What is the shelf life of solder paste?

The shelf life of solder paste is typically between 3 to 6 months when stored at the recommended temperature (usually between 0-10°C). Always check the manufacturer’s guidelines for storage and shelf life information. -

How can I prevent solder paste defects?

To minimize solder paste defects, ensure proper storage and handling of the paste, maintain a clean and controlled printing environment, optimize your stencil design and printing parameters, and regularly monitor and inspect the print quality. Proper control of the reflow profile is also crucial for achieving good solder joint formation.

Conclusion

Solder paste is a critical material in surface mount technology assembly, enabling the formation of strong electrical and mechanical bonds between components and PCBs. Understanding the composition, properties, and application process of solder paste is essential for achieving high-quality, reliable solder joints.

By selecting the appropriate solder paste for your application, optimizing your printing and reflow processes, and regularly monitoring and troubleshooting defects, you can ensure the success of your SMT assembly operations. As electronics continue to advance in complexity and miniaturization, the role of solder paste in enabling these technologies will only become more important.

Leave a Reply