Rogers RT/duroid 6202PR is a high-performance laminate material that has gained popularity in recent years. This material is used in various applications, including military and aerospace industries, where the demand for high-quality and reliable materials is essential. The RT/duroid 6202PR is a thermoset material that has excellent electrical properties, high thermal stability, and low moisture absorption.

The Rogers RT/duroid 6202PR is a PTFE composite material that has a woven glass reinforcement. The material is known for its low dielectric constant and loss, making it an ideal choice for high-frequency applications. The material is also resistant to chemicals and has a low coefficient of thermal expansion, which makes it an excellent choice for applications that require stability over a wide range of temperatures.

Overall, the Rogers RT/duroid 6202PR is a reliable and high-performance material that has been widely adopted in various industries. Its excellent electrical properties, high thermal stability, and low moisture absorption make it an ideal choice for applications that demand high-quality and reliable materials.

Fundamental Characteristics of Rogers RT/Duroid 6202PR

Rogers RT/Duroid 6202PR is a high-performance laminate material that is widely used in the microwave and RF industry. This material is known for its excellent electrical properties, mechanical stability, and thermal performance. In this section, we will discuss the fundamental characteristics of Rogers RT/Duroid 6202PR.

Dielectric Constant and Loss Tangent

The dielectric constant and loss tangent are the two most important electrical properties of any laminate material. Rogers RT/Duroid 6202PR has a low dielectric constant of 2.94 at 10 GHz and a low loss tangent of 0.0013 at 10 GHz. These values make it an ideal material for high-frequency applications where low loss and high stability are required.

Thermal Performance

Rogers RT/Duroid 6202PR has a high thermal conductivity of 0.7 W/mK, which makes it an excellent choice for applications that require high thermal performance. This material has a low coefficient of thermal expansion, which means it can withstand extreme temperatures without losing its mechanical stability.

Mechanical Stability

Rogers RT/Duroid 6202PR has excellent mechanical stability, which makes it an ideal material for applications that require high reliability. This material has a high glass transition temperature of 280°C and can withstand high mechanical stresses without losing its structural integrity.

Other Characteristics

Rogers RT/Duroid 6202PR is a flame-retardant material that meets UL 94V-0 standards. This material is also resistant to chemicals, moisture, and UV radiation, which makes it an ideal choice for outdoor applications.

In summary, Rogers RT/Duroid 6202PR is a high-performance laminate material that has excellent electrical properties, thermal performance, and mechanical stability. These characteristics make it an ideal material for high-frequency and high-reliability applications.

Composition and Structure

Core Material

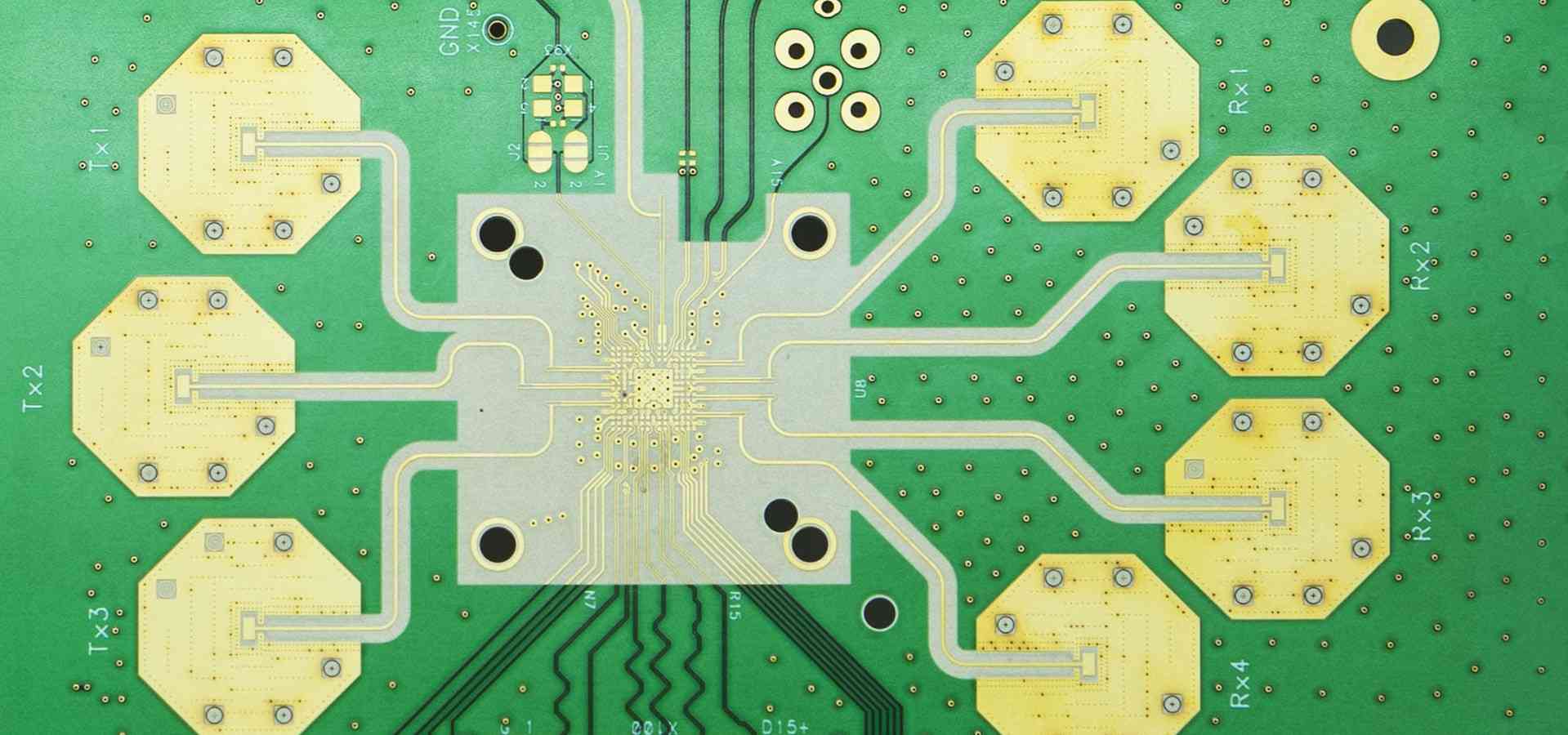

Rogers RT/duroid 6202PR is a high-performance laminate material used in the manufacturing of printed circuit boards (PCBs). The core material of the 6202PR is composed of a reinforced woven fiberglass fabric impregnated with a thermoset resin system. The woven fiberglass provides excellent mechanical strength and dimensional stability, while the resin system offers high dielectric constant and low loss characteristics.

The core material of the RT/duroid 6202PR is available in different thicknesses, ranging from 0.005″ to 0.500″. The thickness of the core material determines the dielectric constant and loss tangent of the laminate. The dielectric constant of the 6202PR ranges from 2.94 to 3.17, depending on the thickness of the core material.

Cladding Material

The cladding material of the RT/duroid 6202PR is a thin layer of copper foil laminated to both sides of the core material. The copper foil provides a conductive surface for the PCB traces and components. The thickness of the copper foil ranges from 0.5 oz to 2 oz per square foot.

The cladding material of the 6202PR is available in different finishes, including electrolytic nickel-gold (ENIG), immersion silver, and immersion tin. These finishes provide a protective layer on the copper surface, preventing oxidation and improving solderability.

In summary, the Rogers RT/duroid 6202PR is a high-performance laminate material composed of a reinforced woven fiberglass core material and copper foil cladding material. The core material provides excellent mechanical strength and dielectric properties, while the cladding material offers a conductive surface for the PCB traces and components.

Key Properties

Electrical Properties

Rogers RT/duroid 6202PR is a high-performance circuit material with excellent electrical properties. It has a dielectric constant of 2.94 and a dissipation factor of 0.0013 at 10 GHz. This makes it ideal for high-frequency applications where low loss and high signal integrity are critical. Additionally, it has a low coefficient of thermal expansion (CTE) which ensures consistent electrical performance over a wide temperature range.

Thermal Properties

The thermal properties of Rogers RT/duroid 6202PR are also impressive. It has a thermal conductivity of 0.7 W/mK, which allows for efficient heat dissipation in high-power applications. It also has a low thermal coefficient of expansion (TCE), which means that it maintains its shape and size even under extreme temperature changes. These thermal properties make it suitable for use in harsh environments where temperature fluctuations are common.

Mechanical Properties

In addition to its electrical and thermal properties, Rogers RT/duroid 6202PR also has excellent mechanical properties. It has a high tensile strength of 14,000 psi, which ensures that it can withstand high mechanical stresses without breaking or deforming. It also has a high flexural strength of 27,000 psi, which allows it to bend without cracking or breaking. These mechanical properties make it ideal for use in applications where durability and reliability are crucial.

Overall, Rogers RT/duroid 6202PR is a high-performance circuit material that offers excellent electrical, thermal, and mechanical properties. Its combination of low loss, high signal integrity, and reliable performance make it an ideal choice for a wide range of high-frequency applications.

Manufacturing Process

The Rogers RT/duroid 6202PR is a high-performance circuit board material that is widely used in the electronics industry. The manufacturing process for this material involves several steps, each of which is critical to the final product’s quality and performance.

The first step in the manufacturing process is the preparation of the substrate material. The substrate is made of fiberglass reinforced with epoxy resin. The substrate is cut into the desired size and shape, and then cleaned to remove any dirt or debris that could affect the material’s properties.

Once the substrate is prepared, a layer of copper foil is laminated onto it. The copper foil is carefully bonded to the substrate using heat and pressure, ensuring a strong and uniform bond between the two materials.

After the copper foil is laminated onto the substrate, the material is drilled to create holes for the components. The holes are then plated with copper to create electrical connections between the layers of the board.

Next, a layer of photoresist is applied to the surface of the copper foil. The photoresist is then exposed to ultraviolet light through a photomask, which creates a pattern on the surface of the material. The areas of the copper foil that are not covered by the photoresist are then etched away, leaving behind the desired circuit pattern.

Finally, the material is coated with a layer of solder mask, which protects the copper traces and pads from oxidation and other forms of damage. The solder mask is then cured using heat, creating a durable and protective layer that is essential for the material’s long-term reliability.

Overall, the manufacturing process for the Rogers RT/duroid 6202PR is a complex and precise process that requires specialized equipment and expertise. By following these steps carefully, manufacturers can create high-quality circuit board materials that meet the demanding requirements of modern electronics applications.

Applications of Rogers RT/Duroid 6202PR

Telecommunications

Rogers RT/Duroid 6202PR is a popular choice for telecommunications applications. Its high dielectric constant and low loss tangent make it suitable for use in high-frequency circuits, such as those found in cellular base stations, satellite communications, and radar systems. The material’s low moisture absorption rate also helps maintain stable electrical performance over time.

Aerospace

The aerospace industry relies on Rogers RT/Duroid 6202PR for its high-performance capabilities. The material’s high thermal stability and low coefficient of thermal expansion make it ideal for use in harsh environments, such as those found in satellites, aircraft, and spacecraft. Its low outgassing properties also make it suitable for use in vacuum environments.

Automotive

Rogers RT/Duroid 6202PR is increasingly being used in the automotive industry for its high-frequency performance and durability. Its low dielectric loss makes it suitable for use in automotive radar systems, while its high thermal stability allows it to withstand the high temperatures found in engine compartments. Additionally, its low moisture absorption rate and chemical resistance make it ideal for use in harsh automotive environments.

In summary, Rogers RT/Duroid 6202PR is a versatile material with a wide range of applications in telecommunications, aerospace, and automotive industries. Its high-performance capabilities, stability, and durability make it a popular choice for high-frequency circuits and harsh environments.

Advantages and Limitations

Rogers RT/duroid 6202PR is a high-performance laminate material that offers several advantages. It is widely used in various applications due to its excellent electrical properties and mechanical strength.

Advantages

-

Low dielectric constant and loss tangent: The RT/duroid 6202PR has a low dielectric constant and loss tangent, which makes it an ideal material for high-frequency applications. It offers excellent signal integrity and low insertion loss, making it suitable for microwave and millimeter-wave circuits.

-

High thermal conductivity: The RT/duroid 6202PR has a high thermal conductivity, which makes it an excellent choice for applications that require efficient heat dissipation. It can handle high power levels without overheating, making it suitable for power amplifiers and other high-power applications.

-

Good mechanical strength: The RT/duroid 6202PR has good mechanical strength, which makes it resistant to bending and flexing. It can withstand harsh environments and is suitable for applications that require high reliability.

Limitations

-

High cost: The RT/duroid 6202PR is a high-performance material, which means that it is more expensive than other laminate materials. It may not be suitable for applications that require low-cost solutions.

-

Difficult to machine: The RT/duroid 6202PR is a hard material, which makes it difficult to machine. It requires specialized equipment and expertise to fabricate, which can increase the cost and lead time of the project.

-

Limited availability: The RT/duroid 6202PR is not widely available, which can make it difficult to source. It may not be suitable for applications that require large quantities of material.

In summary, the RT/duroid 6202PR offers excellent electrical properties and mechanical strength, making it suitable for high-frequency and high-power applications. However, it is more expensive than other materials, difficult to machine, and not widely available.

Conclusion

In summary, Rogers RT/duroid 6202PR is a high-performance laminate material that offers excellent electrical properties, thermal stability, and mechanical strength. Its low dielectric constant and loss tangent make it an ideal choice for high-frequency applications, while its high glass transition temperature and low coefficient of thermal expansion ensure reliable performance in harsh environments.

Furthermore, the material is easy to process and can be used in a variety of applications, including aerospace, defense, and telecommunications. It is also compatible with a wide range of fabrication methods, such as drilling, routing, and laser cutting.

Overall, Rogers RT/duroid 6202PR is a reliable and versatile material that meets the demanding requirements of modern electronic applications. Its exceptional performance and ease of use make it an excellent choice for designers and engineers looking to optimize their designs for high-frequency and high-speed applications.

Leave a Reply