The Rogers RO4700 is a popular electronic component that has been used in a wide range of applications, from consumer electronics to industrial equipment. This versatile component is known for its high performance, reliability, and ease of use, making it a favorite among engineers and hobbyists alike.

One of the key features of the Rogers RO4700 is its high dielectric constant, which makes it ideal for use in applications that require high-frequency performance. This component is also known for its low loss tangent, which helps to minimize signal distortion and maintain signal integrity. Additionally, the Rogers RO4700 is easy to process and can be used in a variety of manufacturing techniques, including lamination, casting, and injection molding.

Overall, the Rogers RO4700 is an excellent choice for anyone looking for a high-performance electronic component that is reliable, easy to use, and versatile. Whether you are working on a consumer electronics project or designing industrial equipment, the Rogers RO4700 is sure to meet your needs and exceed your expectations.

Overview of Rogers RO4700

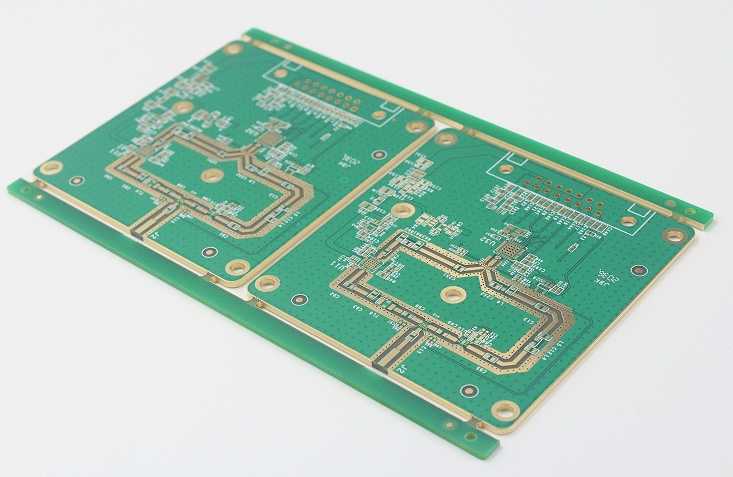

Rogers RO4700 is a high-performance laminate material that is widely used in the electronics industry. It is a glass-reinforced hydrocarbon/ceramic material that offers excellent electrical, mechanical, and thermal properties. The material is suitable for use in a wide range of applications, including high-frequency circuits, microwave circuits, and power amplifiers.

One of the key features of Rogers RO4700 is its low dielectric constant and loss tangent, which makes it an excellent choice for high-frequency applications. The material has a dielectric constant of 2.55 and a loss tangent of 0.0013 at 10 GHz, which makes it one of the best-performing materials in its class.

Another advantage of Rogers RO4700 is its excellent thermal stability. The material has a Tg of 280°C and can withstand high temperatures without losing its electrical or mechanical properties. This makes it an ideal choice for applications that require high-temperature stability, such as power amplifiers and high-frequency circuits.

Rogers RO4700 is also known for its excellent mechanical properties. The material is highly resistant to impact, vibration, and thermal shock, which makes it a popular choice for applications that require high reliability and durability.

Overall, Rogers RO4700 is a high-quality laminate material that offers excellent electrical, mechanical, and thermal properties. Its low dielectric constant and loss tangent, high-temperature stability, and excellent mechanical properties make it an ideal choice for a wide range of applications in the electronics industry.

Key Features of Rogers RO4700

High Frequency Performance

Rogers RO4700 is a high-performance circuit material that offers excellent electrical properties at high frequencies. It is designed to provide low insertion loss, low dielectric constant, and low dielectric loss, making it ideal for high-frequency applications. The material is suitable for use in microwave and millimeter-wave applications, including 5G wireless, aerospace, and defense.

Thermal Conductivity

Rogers RO4700 has a high thermal conductivity, which makes it an excellent choice for applications that require efficient heat dissipation. The material has a thermal conductivity of 0.6 W/mK, which allows it to dissipate heat quickly and effectively. This property makes it suitable for use in power amplifiers, transmitters, and other high-power applications.

Low Dielectric Loss

Rogers RO4700 has a low dielectric loss, which means that it can transmit signals with minimal attenuation. The material has a dielectric loss tangent of 0.0009, which is one of the lowest in the industry. This property makes it ideal for high-frequency applications that require low signal loss and high signal integrity.

In summary, Rogers RO4700 is a high-performance circuit material that offers excellent electrical properties at high frequencies. It has a high thermal conductivity, low dielectric constant, and low dielectric loss, making it an ideal choice for high-frequency applications that require efficient heat dissipation and low signal loss.

Applications of Rogers RO4700

Antennas

Rogers RO4700 is a popular choice for designing antennas. The material’s low dielectric loss and high thermal stability make it ideal for creating high-performance antennas that can withstand harsh environmental conditions. RO4700’s excellent dimensional stability also ensures that antenna designs are accurate and consistent.

Power Amplifiers

RO4700 is commonly used in the design of power amplifiers for wireless communication systems. The material’s high thermal conductivity and low thermal expansion coefficient provide excellent heat dissipation, which is essential for maintaining the stability and reliability of power amplifiers. RO4700’s low dielectric loss also helps to improve the efficiency of power amplifiers.

Filters

RO4700 is an excellent material for designing filters for microwave and millimeter-wave applications. The material’s low dielectric loss and high thermal stability help to maintain the accuracy and stability of filter designs. RO4700’s excellent dimensional stability also ensures that filter designs are consistent and reliable.

In summary, Rogers RO4700 is a versatile material that can be used in a wide range of applications, including antennas, power amplifiers, and filters. Its unique combination of low dielectric loss, high thermal stability, and excellent dimensional stability make it an excellent choice for designing high-performance wireless communication systems.

Handling and Processing of Rogers RO4700

Machining

Rogers RO4700 is a versatile material that can be easily machined using standard CNC equipment. It can be drilled, milled, and turned to create complex geometries with tight tolerances. The material is relatively easy to work with and can be machined quickly and efficiently.

However, it is important to note that the material is quite abrasive and can wear down cutting tools quickly. Therefore, it is recommended to use carbide or diamond tools when machining Rogers RO4700. Additionally, it is important to use a coolant or lubricant to prevent overheating and prolong the life of the cutting tools.

Bonding

Rogers RO4700 is an excellent material for bonding applications. It can be bonded to a variety of substrates, including metals, plastics, and ceramics. The material has a low coefficient of thermal expansion, which makes it ideal for bonding to materials with different thermal expansion properties.

When bonding Rogers RO4700, it is important to use a high-quality adhesive that is compatible with the material. The surface of the material should be cleaned and prepared properly before bonding to ensure a strong and durable bond. It is recommended to follow the manufacturer’s instructions when bonding Rogers RO4700.

Plating

Rogers RO4700 can be plated with a variety of metals, including gold, silver, and nickel. The material has good adhesion properties, which makes it ideal for plating applications. The plating process can be done using standard electroplating techniques.

When plating Rogers RO4700, it is important to clean and prepare the surface of the material properly to ensure good adhesion of the plating material. The thickness of the plating layer should be controlled carefully to ensure that it meets the desired specifications. It is recommended to follow the manufacturer’s instructions when plating Rogers RO4700.

Overall, Rogers RO4700 is a versatile material that can be easily handled and processed. It is important to follow the manufacturer’s instructions when working with the material to ensure that it is used safely and effectively.

Comparison with Other Materials

When considering materials for electronic circuit board substrates, Rogers RO4700 is often compared to other high-performance materials such as FR-4, PTFE, and ceramic-based materials. Each material has its unique advantages and disadvantages, and choosing the right material depends on the specific application requirements.

FR-4

FR-4 is a widely used substrate material due to its low cost and good electrical properties. However, compared to Rogers RO4700, FR-4 has lower dielectric constant and dissipation factor, which can limit its use in high-frequency applications. Additionally, FR-4 has poor thermal conductivity and can be prone to delamination under high-temperature and high-humidity conditions.

PTFE

PTFE-based materials, such as Rogers RT/duroid, have excellent electrical properties and are widely used in high-frequency applications. However, PTFE materials are typically more expensive than FR-4 and can be more difficult to process. PTFE materials also have lower mechanical strength and can be prone to cracking and breaking under mechanical stress.

Ceramic-Based Materials

Ceramic-based materials, such as aluminum oxide and aluminum nitride, have excellent thermal conductivity and mechanical strength, making them suitable for high-power applications. However, ceramic materials are brittle and can be difficult to process. They also have lower dielectric constant and dissipation factor compared to Rogers RO4700, which can limit their use in high-frequency applications.

In summary, Rogers RO4700 offers a balance of high-frequency performance, thermal conductivity, and mechanical strength, making it a suitable choice for a wide range of electronic applications. However, it is important to consider the specific application requirements and compare the material properties of other substrates before making a final decision.

Conclusion

The Rogers RO4700 is a solid choice for those looking for a high-quality material for their electronic applications. The material has a low dielectric constant, low loss, and a high thermal conductivity, making it ideal for high-frequency applications. Additionally, the material has a low coefficient of thermal expansion, which makes it highly stable over a wide range of temperatures.

The RO4700 is also easy to process, making it an attractive option for manufacturers. It can be machined, drilled, and cut with ease, making it simple to create complex shapes and designs. The material also has good adhesion properties, which makes it easy to bond to other materials.

One potential drawback of the RO4700 is its cost. It is a premium material, and as such, it may not be the best choice for those on a tight budget. However, for those who require the high-performance characteristics of the material, the cost may be justified.

Overall, the Rogers RO4700 is a reliable and high-quality material that is well-suited for a variety of electronic applications. Its excellent electrical and thermal properties, combined with its ease of processing, make it a top choice for many manufacturers in the industry.

Leave a Reply