Rogers RO3003G2 is a high-frequency laminate material that is commonly used in the manufacture of high-frequency printed circuit boards. This material is designed to provide excellent electrical performance at high frequencies, making it ideal for use in a wide range of applications, including wireless communication systems, radar systems, and satellite communications.

One of the key features of Rogers RO3003G2 is its low dielectric constant and loss, which allows for high signal integrity and low insertion loss. This material also has excellent thermal stability, which means it can maintain its electrical properties even at high temperatures. Additionally, Rogers RO3003G2 has a low coefficient of thermal expansion, which makes it an ideal choice for applications that require high reliability and stability over a wide temperature range.

Overall, Rogers RO3003G2 is a high-performance laminate material that is widely used in the electronics industry for its excellent electrical performance and thermal stability. Whether you are designing a high-frequency circuit for a wireless communication system or a radar system, Rogers RO3003G2 is a reliable and high-quality choice that can help you achieve excellent results.

Material Properties of Rogers RO3003G2

Rogers RO3003G2 is a high-frequency laminate material that is commonly used in the manufacture of printed circuit boards (PCBs) for RF/microwave applications. The material is known for its excellent electrical properties, high thermal conductivity, and low loss tangent.

The following are some of the key material properties of Rogers RO3003G2:

Dielectric Constant (Dk)

The dielectric constant of Rogers RO3003G2 is typically around 3.00 at 10 GHz. This makes it an ideal material for use in high-frequency applications where low signal loss and good signal integrity are critical.

Loss Tangent (Df)

The loss tangent of Rogers RO3003G2 is typically around 0.0015 at 10 GHz. This low value indicates that the material has low signal loss and is highly efficient in transmitting signals.

Thermal Conductivity

The thermal conductivity of Rogers RO3003G2 is typically around 1.44 W/mK. This high thermal conductivity allows for efficient dissipation of heat generated by high-power circuits, which helps to prevent overheating and damage to the PCB.

Tensile Strength

The tensile strength of Rogers RO3003G2 is typically around 150 MPa. This high strength makes the material resistant to cracking and breaking under mechanical stress, which is important for maintaining the integrity of the PCB.

Water Absorption

The water absorption of Rogers RO3003G2 is typically less than 0.04%. This low water absorption makes the material resistant to moisture and humidity, which can degrade the performance of the PCB.

Overall, Rogers RO3003G2 is a high-quality laminate material that is ideal for use in high-frequency applications where low signal loss, good signal integrity, and efficient heat dissipation are critical.

Applications of Rogers RO3003G2

Telecommunications

Rogers RO3003G2 is a high-frequency laminate material that is widely used in the telecommunications industry. It offers excellent electrical performance, low loss, and high thermal conductivity, making it ideal for applications such as high-speed digital and RF circuits, antennas, and power amplifiers.

The material’s low dielectric constant and loss tangent enable it to deliver high signal integrity and low insertion loss, which are essential for high-frequency applications. Additionally, the material’s high thermal conductivity helps to dissipate heat efficiently, ensuring reliable performance even under high power conditions.

Automotive

Rogers RO3003G2 is also used in the automotive industry for applications such as radar systems, collision avoidance systems, and infotainment systems. The material’s high-frequency performance and low loss make it ideal for these applications, which require reliable and accurate signal transmission.

Moreover, the material’s high thermal conductivity ensures that it can withstand the high temperatures that are typical in automotive applications, ensuring reliable performance even under extreme conditions.

Aerospace

Rogers RO3003G2 is widely used in the aerospace industry for applications such as satellite communication systems, radar systems, and avionics. The material’s high-frequency performance, low loss, and high thermal conductivity make it ideal for these applications, which require high reliability and performance.

The material’s low dielectric constant and loss tangent enable it to deliver high signal integrity and low insertion loss, which are critical for aerospace applications. Additionally, the material’s high thermal conductivity helps to dissipate heat efficiently, ensuring reliable performance even in extreme temperature conditions.

In conclusion, Rogers RO3003G2 is a high-performance laminate material that is widely used in the telecommunications, automotive, and aerospace industries. Its excellent electrical performance, low loss, and high thermal conductivity make it ideal for high-frequency applications that require reliable and accurate signal transmission.

Manufacturing Process

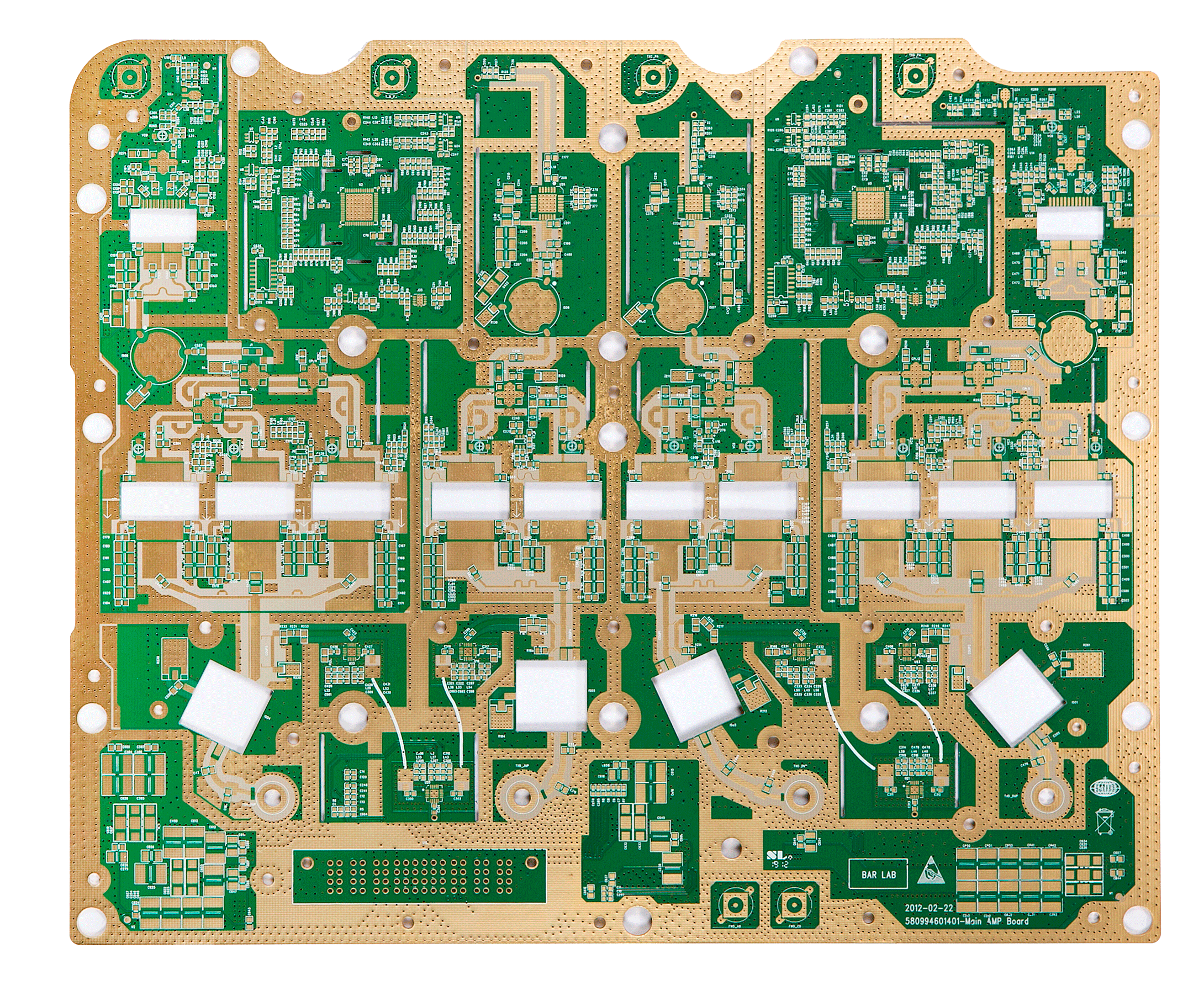

Rogers RO3003G2 is a high-frequency laminate material that is widely used in the manufacture of printed circuit boards (PCBs). The manufacturing process for Rogers RO3003G2 involves several steps, including resin impregnation, lamination, and drilling.

The first step in the manufacturing process is resin impregnation, which involves the impregnation of the substrate material with a thermosetting resin. The resin is then cured at high temperatures and under high pressure to create a solid, uniform substrate material.

The next step is lamination, which involves the bonding of multiple layers of the substrate material together using heat and pressure. The resulting laminate material is then cooled and trimmed to the desired size and thickness.

Finally, the laminate material is drilled to create the necessary holes for the components to be mounted on the PCB. The holes are then plated with copper to provide electrical conductivity and to ensure that the components are securely mounted on the board.

Overall, the manufacturing process for Rogers RO3003G2 is a complex and precise process that requires careful attention to detail and high-quality materials. The resulting laminate material is a reliable and high-performance substrate that is widely used in a variety of applications, including telecommunications, aerospace, and defense.

Advantages of Rogers RO3003G2

Rogers RO3003G2 is a high-frequency circuit material that offers several advantages over other materials in the market. In this section, we will discuss its benefits, which include:

Low Dielectric Loss

One of the most significant advantages of Rogers RO3003G2 is its low dielectric loss. This property makes it an excellent choice for high-frequency applications, where signal loss is a significant concern. With a dielectric loss of 0.0017 at 10 GHz, this material provides excellent signal integrity and reduces the need for additional amplification or signal conditioning.

High Thermal Conductivity

Another advantage of Rogers RO3003G2 is its high thermal conductivity. This property allows it to dissipate heat quickly, making it suitable for high-power applications. With a thermal conductivity of 1.24 W/mK, this material can handle high temperatures without compromising its electrical performance.

Consistent Electrical Performance

Rogers RO3003G2 also offers consistent electrical performance across different frequencies and temperatures. This property makes it an ideal choice for applications that require stable and reliable performance over a wide range of conditions. With a dielectric constant of 3.00 and a loss tangent of 0.0013, this material provides excellent electrical performance across a wide range of frequencies.

Ease of Processing

Finally, Rogers RO3003G2 is easy to process, making it an excellent choice for high-volume production. This material can be machined, drilled, and plated using standard PCB manufacturing processes, reducing production costs and lead times.

In summary, Rogers RO3003G2 offers several advantages over other high-frequency circuit materials, including low dielectric loss, high thermal conductivity, consistent electrical performance, and ease of processing. These properties make it an excellent choice for a wide range of applications, including wireless communications, aerospace, and defense.

Limitations of Rogers RO3003G2

Despite its many advantages, the Rogers RO3003G2 has a few limitations that users should be aware of before choosing this material for their projects.

Limited Availability

One of the main limitations of the Rogers RO3003G2 is its limited availability. This material is not as widely available as some other PCB materials, which can make it difficult to source for certain projects. Additionally, the limited availability of this material can result in higher prices, which may not be feasible for some projects with tight budgets.

High Cost

Another limitation of the Rogers RO3003G2 is its high cost. This material is more expensive than some other PCB materials, which can make it a less attractive option for projects with limited budgets. While the high cost is justified by the material’s high performance and reliability, it may not be feasible for all projects.

Limited Thickness Options

The Rogers RO3003G2 is also limited in terms of thickness options. This material is only available in a few thicknesses, which may not be suitable for all projects. Additionally, the limited thickness options can make it difficult to achieve certain design requirements, which may require additional design work or the use of a different material.

In conclusion, while the Rogers RO3003G2 has many advantages, it also has a few limitations that users should be aware of before choosing this material for their projects. These limitations include limited availability, high cost, and limited thickness options.

Comparative Analysis

When it comes to high-frequency circuit materials, Rogers RO3003G2 is a popular choice. However, it’s always important to compare it to other options on the market to make an informed decision. In this section, we’ll compare RO3003G2 with two other circuit materials: FR-4 and PTFE.

FR-4

FR-4 is a widely used circuit material due to its low cost and availability. However, it has limitations when it comes to high-frequency applications. Compared to RO3003G2, FR-4 has a higher dielectric constant and loss tangent, which can lead to increased signal attenuation and distortion. Additionally, FR-4 is not suitable for high-temperature applications.

PTFE

PTFE (polytetrafluoroethylene) is a high-performance circuit material known for its low dielectric constant and loss tangent, making it ideal for high-frequency applications. However, it’s more expensive than FR-4 and has limitations when it comes to mechanical strength and dimensional stability. Compared to RO3003G2, PTFE has a lower thermal conductivity, which can lead to increased temperature rise in high-power applications.

RO3003G2

RO3003G2 is a high-frequency circuit material that offers a balance of performance and cost-effectiveness. Compared to FR-4, it has a lower dielectric constant and loss tangent, which results in lower signal attenuation and distortion. Compared to PTFE, it has better mechanical strength and dimensional stability, making it suitable for a wider range of applications. Additionally, RO3003G2 has a higher thermal conductivity than PTFE, which can help dissipate heat in high-power applications.

In summary, RO3003G2 offers a balance of performance and cost-effectiveness, making it a popular choice for high-frequency circuit applications. While FR-4 is a low-cost option, it has limitations when it comes to high-frequency applications. PTFE is a high-performance option, but it’s more expensive and has limitations when it comes to mechanical strength and dimensional stability.

Future Prospects

The future prospects of Rogers RO3003G2 are looking bright. As the demand for high-frequency applications continues to grow, this material is expected to play an important role in meeting those needs. Here are a few reasons why:

-

Excellent electrical performance: The RO3003G2 has low dielectric loss, high thermal conductivity, and low loss tangent. These properties make it ideal for high-frequency applications where signal integrity is critical.

-

Versatility: The material can be used in a variety of applications, including antennas, filters, amplifiers, and more. Its compatibility with a range of fabrication methods, such as etching, drilling, and milling, makes it a flexible option for manufacturers.

-

Reliability: Rogers is known for producing high-quality materials that meet stringent industry standards. The RO3003G2 is no exception. Its stable dielectric constant and low moisture absorption ensure that it performs consistently over time.

Looking ahead, we can expect to see Rogers RO3003G2 continue to be a popular choice for high-frequency applications. As new technologies emerge, the material will likely be adapted to meet the changing needs of the market. With its excellent electrical performance, versatility, and reliability, it is poised to remain a leading option for years to come.

Leave a Reply