Introduction to Rogers MAGTREX

Rogers MAGTREX is a ceramic-filled, thermoset laminate material designed for high reliability and performance in power electronics, electric motor drives, and other magnetics-intensive applications.

With a dielectric constant of 3.5, MAGTREX provides a stable foundation for the construction of magnetic components like inductors and transformers integrated directly into a printed circuit board (PCB).

Key features of Rogers MAGTREX laminates include:

- Stable dielectric constant of 3.5

- Excellent thermal conductivity for heat dissipation

- High breakdown voltage strength

- Low coefficient of thermal expansion (CTE)

- Lead-free compatible for harsh environments

- Enables embedded magnetics and inductors

MAGTREX allows power designers to integrate magnetic devices into PCBs, eliminating the need for discrete magnetics while enhancing reliability.

Rogers MAGTREX Material Properties

Rogers MAGTREX possesses a robust set of properties that make it ideal for power electronics and drives:

Stable Dielectric Constant

- Dielectric constant of 3.5 (+/-0.05)

- Consistent across operating temperature range

- Provides precision impedance control

High Thermal Conductivity

- 1.5 W/mK thermal conductivity

- Efficiently dissipates heat from components

High Dielectric Strength

- Withstands voltage spikes from switching circuits

- Allows thinner dielectric layers

Low Coefficient of Thermal Expansion

- CTE of 17 ppm/°C (x,y)

- Enhanced mechanical stability

Lead-Free Assembly Compatible

- Withstands peak temperatures up to 300°C

- Reliable performance in harsh environments

Key Material Properties Summary

| Property | Value |

|---|---|

| Dielectric Constant | 3.5 (+/-0.05) |

| Thermal Conductivity | 1.5 W/mK |

| Dielectric Strength | >300 V/mil |

| CTE (x,y) | 17 ppm/°C |

| Tg | >280°C |

Rogers MAGTREX Laminate Copper Cladding

Rogers MAGTREX laminates are clad with electrodeposited copper:

- 1⁄2, 1, 2 oz standard foils

- Heavier copper up to 6 oz for high current capacity

- Low profile foils for high frequency switching

- Reverse treat and double treat foils for adhesion

Copper thickness is selected based on electrical and thermal requirements.

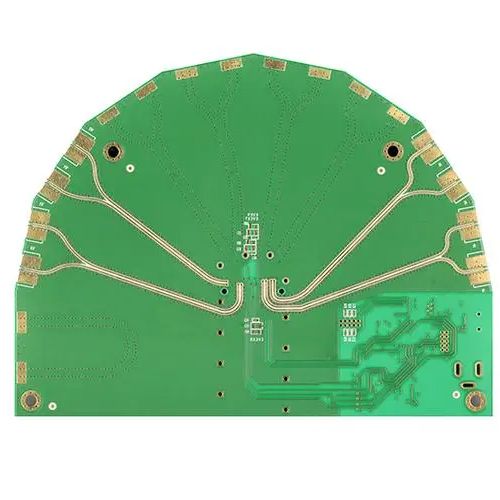

PCB Design with Rogers MAGTREX

To fully utilize Rogers MAGTREX performance in power PCBs, certain design guidelines should be followed:

Account for Stable Dielectric

- Use precise geometries for controlled impedances

- Model parameters across temperature range

Incorporate Thermal Management

- Thermal vias for heat spreading

- Backside cooling features if needed

- Avoid excessive thermal gradients

Manage Voltage Stress

- Maximize creepage and clearance distances

- Allow for some material thickness variation

- Incorporate spacing for voltage transients

Enable Embedded Magnetics

- Define cross-sectional area for inductors

- Model expected inductance and resistance

- Verify core does not saturate

Prototyping and field testing helps validate the performance prior to full release.

PCB Fabrication with Rogers MAGTREX

Rogers MAGTREX laminates can be fabricated into PCBs using standard processes:

Imaging and Etching

- Compatible with liquid photoresists

- Etches well in ammoniacal or cupric chloride

Hole Drilling

- Use mechanical drilling or punching

- Laser drilling available for fine features

Plating and Lamination

- Electroless copper or direct metallization

- Bond with prepregs and adhesive films

Final Finishes

- ENIG, immersion silver, immersion tin, OSP

- HASL for high current connections

Additional steps may be needed to fully cure bondplys and inks.

Rogers MAGTREX Material Availability

Rogers MAGTREX laminates are offered under the RO4830TM product designation with standard offerings:

| Material | Description |

|---|---|

| RO4830 (005) | 0.005” (0.127mm) dielectric |

| RO4830 (010) | 0.010” (0.254mm) dielectric |

| RO4830 (020) | 0.020” (0.508mm) dielectric |

| RO4830 (030) | 0.030” (0.762mm) dielectric |

- Sheet sizes up to 18” x 24”

- Prepregs available for multilayer boards

- Custom dielectric thicknesses upon request

Quick-turn fabrication services enable fast prototyping.

Rogers MAGTREX Laminate Applications

The unique properties of Rogers MAGTREX make it well suited for:

Power Conversion

- AC/DC and DC/DC converter PCBs

- POL regulators and modules

- Solar inverters and converters

Motor Drives and Controllers

- Servo motor control boards

- BLDC motor drives

- Stepper motor drivers

Power Supplies

- Switch mode power supplies

- Power factor correction stages

- DC power distribution panels

Battery Management

- Battery charging and monitoring circuits

- Battery packs and interconnects

Magnetics Integration

- Inductors, transformers, and chokes

- Integrated magnetic components

Considerations for Rogers MAGTREX

While providing many benefits, some factors to consider when selecting Rogers MAGTREX include:

- Higher cost than standard FR-4 laminates

- Processing may require additional controls

- Lead times typically longer than standard materials

- Susceptible to thermal stresses and shrinkage

- Not compatible with pressing or wave soldering

For many power electronics PCBs with integrated magnetics, MAGTREX delivers the electrical performance and reliability required.

Frequently Asked Questions

What is the Z-axis CTE of Rogers MAGTREX laminates?

The Z-axis coefficient of thermal expansion (CTE) for Rogers MAGTREX laminates is 40 ppm/°C. This matches well with the 17 ppm/°C CTE in the X and Y directions.

Are there flame retardant grades of Rogers MAGTREX available?

Yes, Rogers offers flame retardant grades of MAGTREX for applications requiring UL 94V-0 flammability rating. This includes RO4830G2 laminates which achieve V-0 at a thickness of 0.030 inches.

What types of prepregs can be used with Rogers MAGTREX?

Rogers 3000 and 4000 series prepregs are recommended for multilayer boards with MAGTREX. These include materials like RO4450B, RO4450F, RO3003TM, and RO3010TM prepregs.

What is the maximum operating temperature for Rogers MAGTREX?

Rogers MAGTREX laminates can reliably operate at temperatures up to 130°C. The high glass transition temperature exceeding 280°C provides ample margin for peak excursions during lead-free solder assembly processes.

Can Rogers MAGTREX laminates withstand repeated thermal cycling?

Yes, the matched X, Y, and Z CTE of Rogers MAGTREX enables it to endure repeated temperature cycling with minimal risk of solder joint failure or layer delamination. This makes it suitable for applications in harsh environments.

Leave a Reply