Overview

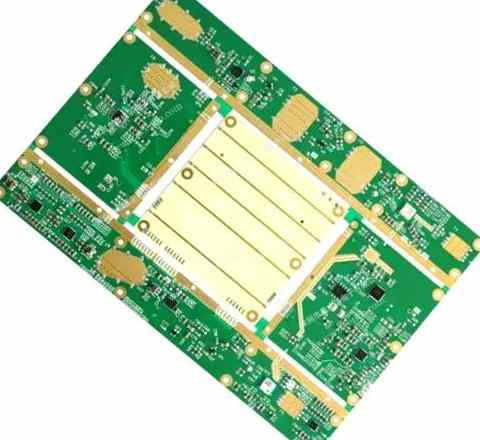

Curamik CoolPower from Rogers Corporation is an innovative direct copper bonded (DCB) ceramic substrate material designed to enable high-power density and reliable thermal management solutions for wide bandgap semiconductors used in electric vehicle power electronics.

Applications

Electric Vehicle Inverters

Curamik CoolPower is ideal for electric vehicle traction inverters that require efficient cooling and high current density. The high thermal conductivity of CoolPower enables lower junction temperatures for silicon carbide (SiC) and gallium nitride (GaN) devices. This allows higher power densities and smaller inverter designs.

On-Board Chargers

On-board electric vehicle chargers can also benefit from Curamik CoolPower substrates. The material’s thermal performance supports high frequency switching for faster charging times. CoolPower’s dielectric strength and electrical conductivity are optimized for charger applications.

DC-DC Converters

High efficiency DC-DC converters used in electric vehicle power systems require robust thermal management. Curamik CoolPower’s dielectric isolation, thermal conductivity, and coefficient of thermal expansion make it well suited for these demanding applications.

Properties

- Thermal conductivity up to 4 times higher than aluminum oxide ceramic

- High dielectric strength

- Closely matched coefficients of thermal expansion

- Highly customizable with different available copper thicknesses

- RoHS compliant and halogen-free

Key Benefits

Enables Higher Current Densities

The excellent thermal conductivity allows cooling directly at the semiconductor junction. This enables higher current densities compared to standard DCB ceramics.

Increases Power Density

By reducing device temperatures, the improved cooling provided by CoolPower substrates enables more compact and efficient power electronic designs.

Extends Semiconductor Lifetime

Lowering junction temperatures improves semiconductor lifetime and long term reliability, especially important for new wide bandgap devices.

Simplifies Design

CoolPower’s thermal expansion match with common baseplates reduces mechanical stress. This allows simple, reliable power module construction.

Frequently Asked Questions

What fabrication options are available?

Rogers can supply finished parts, presintered substrates, or sinterable sheets. A variety of copper thicknesses, solder layers, and surface finishes are offered.

What baseplates are recommended?

CuMo and AlSiC baseplates pair well with CoolPower due to their thermal expansion match. Other options like Al and Cu can also be used.

Can CoolPower be used at high voltages?

Yes, the dielectric strength exceeds typical requirements for traction inverters and on-board chargers. Voltages up to 1.5kVrms have been demonstrated.

What are typical application temperatures?

Curamik CoolPower performs well from -55°C to over 200°C. It maintains excellent thermal conductivity across this wide temperature range.

How does CoolPower’s thermal conductivity compare to other DCB materials?

CoolPower has a thermal conductivity around 4 times higher than standard aluminum oxide DCB ceramic. It also exceeds aluminium nitride DCB substrates.

Leave a Reply