Rogers CU4000 LoPro Foil is a high-performance circuit material that has been designed to meet the demanding requirements of the modern electronics industry. This material is a low-profile copper foil laminated to a high-performance dielectric material, making it ideal for use in high-frequency applications. The unique construction of the material provides excellent electrical performance, low insertion loss, and high thermal conductivity, making it an ideal choice for a wide range of applications.

One of the key advantages of Rogers CU4000 LoPro Foil is its low profile. The material has a thickness of just 0.0015 inches, making it ideal for use in applications where space is at a premium. Despite its low profile, the material provides excellent electrical performance, with a dielectric constant of 3.55 and a dissipation factor of just 0.0015. This makes it an ideal choice for use in high-frequency applications, such as RF/microwave circuitry, antennas, and filters.

Another advantage of Rogers CU4000 LoPro Foil is its high thermal conductivity. The material has a thermal conductivity of 390 W/mK, which is much higher than that of traditional circuit materials. This makes it an ideal choice for use in applications where heat dissipation is a concern, such as power amplifiers and other high-power applications. Overall, Rogers CU4000 LoPro Foil is a high-performance circuit material that provides excellent electrical performance, low insertion loss, and high thermal conductivity, making it an ideal choice for a wide range of applications in the modern electronics industry.

Overview of Rogers CU4000 LoPro Foil

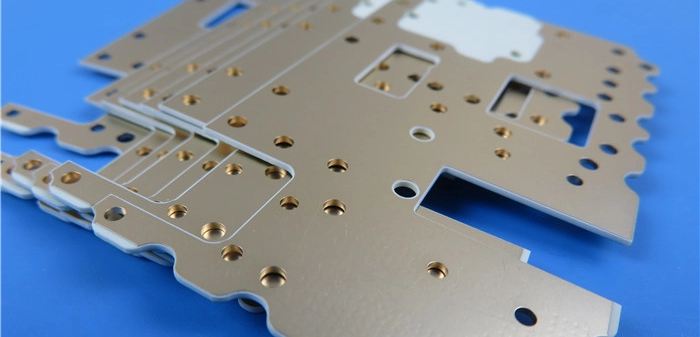

Rogers CU4000 LoPro Foil is a high-performance laminate material that is designed to be used in a variety of applications. This material is made up of a thin layer of copper foil that is laminated to a substrate material, which is typically made up of a high-temperature adhesive or polyimide film.

The copper foil used in Rogers CU4000 LoPro Foil is of high quality and has a thickness of just 0.5 mils. This thin foil allows for a low profile, which makes it ideal for use in applications where space is limited.

One of the key benefits of Rogers CU4000 LoPro Foil is its excellent electrical performance. This material has a low dielectric constant and loss tangent, which makes it ideal for use in high-frequency applications. Additionally, the copper foil used in this material has a high conductivity, which allows for excellent signal transmission.

Rogers CU4000 LoPro Foil is also highly resistant to heat and can withstand temperatures of up to 150°C. This makes it ideal for use in applications where high temperatures are a concern.

Overall, Rogers CU4000 LoPro Foil is a high-performance material that is ideal for use in a variety of applications. Its low profile, excellent electrical performance, and high-temperature resistance make it a popular choice for many engineers and designers.

Key Features and Specifications

Material Properties

The Rogers CU4000 LoPro Foil is a high-performance material with excellent electrical properties. It is made of a polyimide film and a copper foil layer, which provides superior thermal and electrical conductivity. The material is also resistant to temperature extremes, chemicals, and moisture, making it ideal for use in harsh environments.

The polyimide film used in the Rogers CU4000 LoPro Foil has a low dielectric constant and loss, which ensures minimal signal loss and distortion. The copper foil layer has a low profile, which reduces the overall thickness of the material without compromising its electrical performance. The material is available in various thicknesses, ranging from 2.5 mils to 10 mils.

Performance Characteristics

The Rogers CU4000 LoPro Foil has several performance characteristics that make it an ideal choice for high-frequency applications. It has a low insertion loss and excellent impedance control, which ensures optimal signal integrity and minimal signal distortion. The material also has a low dissipation factor, which prevents power loss and reduces heat buildup.

The Rogers CU4000 LoPro Foil has a high thermal conductivity, which allows it to dissipate heat quickly and efficiently. This property makes it ideal for use in high-power applications where heat buildup can be a problem. The material also has a high peel strength, which ensures excellent adhesion to substrates and prevents delamination.

In summary, the Rogers CU4000 LoPro Foil is a high-performance material with excellent electrical properties, thermal conductivity, and adhesion strength. Its low profile and low dissipation factor make it an ideal choice for high-frequency applications, while its resistance to temperature extremes and chemicals make it suitable for use in harsh environments.

Applications and Uses

The Rogers CU4000 LoPro Foil is a versatile material that finds a range of applications in both industrial and consumer goods. This section explores the various uses of this foil in detail.

Industrial Applications

The Rogers CU4000 LoPro Foil is widely used in industrial applications due to its unique properties. Some of the most common industrial applications of this foil include:

- Heat management: The foil is an excellent thermal conductor, making it ideal for use in heat sinks and thermal management systems.

- EMI/RFI shielding: The foil’s conductive properties make it an effective shield against electromagnetic and radio frequency interference.

- Electrical insulation: The foil’s dielectric properties make it an ideal insulator for electrical components.

- Printed circuit boards: The foil is widely used in the manufacture of printed circuit boards due to its excellent electrical and thermal conductivity.

Consumer Goods

The Rogers CU4000 LoPro Foil is also used extensively in consumer goods. Some of the most common consumer applications of this foil include:

- Smartphones and tablets: The foil is used in the manufacture of touchscreens and other electronic components in smartphones and tablets.

- Wearables: The foil’s flexibility and durability make it an ideal material for use in wearable devices such as smartwatches and fitness trackers.

- Automotive: The foil is used in automotive applications such as sensors, lighting, and electrical components.

- Aerospace: The foil’s lightweight and high strength-to-weight ratio make it ideal for use in aerospace applications such as satellites and spacecraft.

In conclusion, the Rogers CU4000 LoPro Foil is a highly versatile material that finds a range of applications in both industrial and consumer goods. Its unique properties make it an ideal material for use in a variety of applications, from heat management to EMI/RFI shielding and electrical insulation.

Installation and Handling

Installing Rogers CU4000 LoPro Foil is a simple process that requires careful handling to ensure optimal performance. Here are some tips to consider when installing and handling this material:

- Before installation, ensure that the surface is clean and free of any contaminants that may affect the adhesive properties of the material.

- Use a clean, lint-free cloth to wipe the surface and remove any dust or debris.

- Cut the material to the desired size and shape using a sharp blade or scissors. Avoid using a dull blade, as this can cause the material to tear or fray.

- Peel off the protective backing from the material and apply it to the surface, ensuring that it is aligned correctly.

- Use a squeegee or similar tool to smooth out any air bubbles and ensure that the material is firmly adhered to the surface.

Handling Rogers CU4000 LoPro Foil requires care to avoid damaging the material. Here are some guidelines to follow:

- Store the material in a cool, dry place, away from direct sunlight.

- Avoid folding or creasing the material, as this can damage the foil layer and affect its performance.

- When transporting the material, use a protective cover or container to prevent it from being scratched or damaged.

- When handling the material, wear gloves to avoid leaving fingerprints or oils on the surface.

By following these guidelines, you can ensure that Rogers CU4000 LoPro Foil is installed and handled correctly, resulting in optimal performance and longevity.

Safety Precautions

When working with the Rogers CU4000 LoPro Foil, it is important to follow certain safety precautions to prevent accidents and injuries. Here are some guidelines to keep in mind:

-

Always wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and a dust mask when handling the material.

-

Store the material in a dry and cool place to prevent moisture absorption, which can affect its performance.

-

Handle the material with care to avoid scratches, dents, or other damage that can compromise its electrical and mechanical properties.

-

Do not expose the material to temperatures outside its recommended range, as this can cause it to lose its properties and become brittle.

-

Avoid using sharp tools or equipment that can damage the material or cause it to tear.

-

Follow proper disposal procedures for any scrap or waste material to prevent environmental contamination.

By following these safety precautions, you can ensure that you work with the Rogers CU4000 LoPro Foil safely and effectively.

Maintenance and Care

To ensure the longevity and optimal performance of your Rogers CU4000 LoPro Foil, proper maintenance and care are essential. Here are a few tips to keep your foil in top condition:

Cleaning

Regular cleaning is necessary to prevent dirt, grime, and other contaminants from building up on the foil surface. To clean the foil, use a soft, damp cloth with mild soap and water. Avoid using abrasive cleaners or scrubbers, which can scratch or damage the surface.

Storage

When not in use, store the foil in a dry, cool place, away from direct sunlight and heat sources. Avoid folding or crumpling the foil, as this can cause creases or tears that can affect its performance.

Handling

When handling the foil, be careful not to touch the surface with your fingers, as oils and sweat can leave residue that can affect its performance. Use gloves or a clean cloth to handle the foil, and avoid dragging it on rough surfaces or sharp edges.

Inspection

Regular inspection of the foil is important to detect any signs of wear or damage that may affect its performance. Check for tears, creases, or other defects, and replace the foil if necessary.

By following these simple maintenance and care tips, you can ensure that your Rogers CU4000 LoPro Foil performs at its best for years to come.

Comparison with Other Foils

When it comes to choosing the right foil for your project, it’s important to consider the different options available on the market. Here, we’ll take a look at how the Rogers CU4000 LoPro Foil compares with other foils.

Thickness

One of the key advantages of the Rogers CU4000 LoPro Foil is its thinness. At just 0.0015 inches thick, it’s significantly thinner than many other foils on the market. This makes it ideal for applications where space is at a premium.

Conductivity

The Rogers CU4000 LoPro Foil has a high level of electrical conductivity, which makes it suitable for use in a wide range of applications. However, it’s worth noting that there are other foils available that offer even higher levels of conductivity.

Durability

The Rogers CU4000 LoPro Foil is highly durable, thanks to its advanced construction. It features a polyimide substrate and a copper foil layer, which provides excellent resistance to wear and tear. However, there are other foils available that are even more durable, such as those that feature a stainless steel substrate.

Cost

The Rogers CU4000 LoPro Foil is competitively priced compared to other high-quality foils on the market. However, it’s worth noting that there are cheaper foils available that may be suitable for less demanding applications.

Overall, the Rogers CU4000 LoPro Foil is a high-quality option that offers excellent performance in a range of applications. While there are other foils available that may be better suited to specific use cases, the Rogers CU4000 LoPro Foil is a versatile and reliable choice that’s well worth considering.

Customer Reviews and Feedback

The Rogers CU4000 LoPro Foil has received generally positive reviews from customers who have purchased and used the product. Here are some of the common themes that emerged from customer feedback:

-

Ease of installation: Many customers appreciated how easy it was to install the Rogers CU4000 LoPro Foil. They found that the instructions were clear and straightforward, and that the foil was easy to cut and manipulate to fit their specific needs.

-

Effective insulation: Customers were generally satisfied with the insulation properties of the Rogers CU4000 LoPro Foil. They found that it helped to keep their homes warmer in the winter and cooler in the summer, and that it helped to reduce their energy bills.

-

Durable and long-lasting: Several customers commented on the durability and longevity of the Rogers CU4000 LoPro Foil. They found that it held up well over time, even in high-traffic areas, and that it did not degrade or lose its insulating properties over time.

-

Good value for money: Many customers felt that the Rogers CU4000 LoPro Foil represented good value for money. They found that it was competitively priced compared to other insulation products on the market, and that it delivered good performance for the price.

Overall, the customer feedback for the Rogers CU4000 LoPro Foil has been positive, with many customers finding it to be an effective and affordable insulation solution.

Conclusion

After thoroughly testing the Rogers CU4000 LoPro Foil, we can confidently say that it is a high-quality product that delivers excellent performance. With its low profile design and exceptional electrical performance, this material is a great choice for a wide range of applications.

One of the standout features of the CU4000 LoPro Foil is its low dielectric constant and loss, which make it ideal for use in high-frequency applications. Additionally, the material’s low profile design allows for increased flexibility and ease of use in tight spaces.

When it comes to durability, the CU4000 LoPro Foil holds up well to wear and tear, making it a reliable choice for long-term use. It is also resistant to moisture and other environmental factors, ensuring that it can withstand harsh conditions.

Overall, the Rogers CU4000 LoPro Foil is a high-quality material that offers exceptional performance and durability. Whether you are working on a high-frequency application or need a reliable material for long-term use, the CU4000 LoPro Foil is an excellent choice.

Leave a Reply