Overview of the R/bak SR 2000 Series

The R/bak SR 2000 Series is a revolutionary portable vapor recovery unit manufactured by R/bak Inc., a subsidiary of the Andover Group. These self-contained units are designed to capture hydrocarbon vapors emitted during truck loading operations in the oil and gas industry. The R/bak SR 2000 Series offers significant advantages over traditional vapor recovery systems and represents a major advancement in environmental protection and worker safety.

Key Features of the R/bak SR 2000 Series

- Fully self-contained, skid-mounted design: The entire vapor recovery system is housed in a rugged skid so it can easily be transported via truck to well sites. No external power or equipment is required.

- Dual-canister adsorption: Uses two activated carbon canisters to adsorb vapors from multiple loading events before needing to be regenerated.

- Automated regeneration system: The unit automatically switches between canisters and regenerates the saturated canister, allowing continuous operation.

- Vapor destruction: An integrated catalytic oxidizer destroys captured vapors without emitting any new volatile compounds.

- Vapor flow capacity: Each unit can handle up to 2000 SCFM vapor flow.

- Real-time monitoring: An integrated PLC allows remote monitoring of all recovery operations.

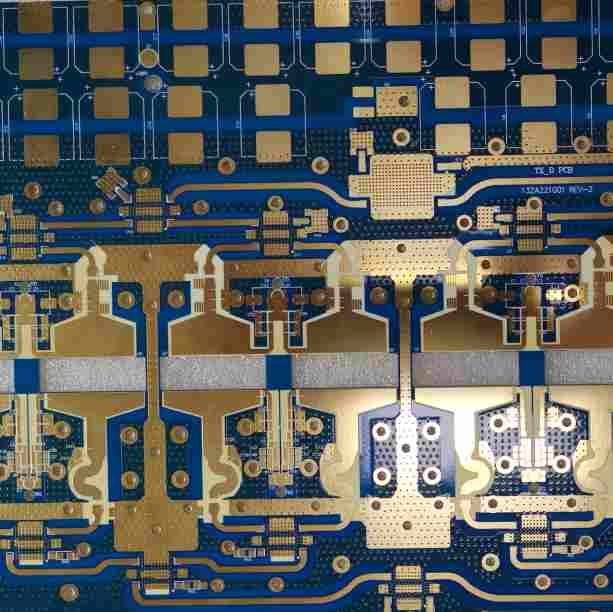

Key Components of the R/bak SR 2000 Series

The R/bak SR 2000 Series vapor recovery unit consists of several key components engineered to work seamlessly together:

- Blower intake system: Draws vapors in from truck loading events.

- Coalescing filter: Removes any liquid hydrocarbons from the vapor stream.

- Activated carbon adsorption canisters: Dual canisters filled with high-capacity activated carbon adsorb vapors.

- Canister switching valves: Allows automated switching between canisters to continue uninterrupted operation.

- Regeneration system: Purges saturated canister with hot nitrogen to prepare it for reuse.

- Catalytic oxidizer: An electric catalytic oxidizer destroys desorbed vapors at high efficiency.

- Vapor flow monitoring: Real-time monitoring of vapor stream with flow meters and sample points.

- Control panel: An integrated PLC control panel allows automated operation and remote monitoring.

Key Benefits of the R/bak SR 2000 Series

The R/bak SR 2000 Series offers numerous benefits that make it an ideal choice for portable well-site vapor recovery:

- Increased job site safety: By capturing harmful vapors, exposure risks for workers are greatly reduced.

- Reduced environmental impact: Destruction of vapors eliminates a significant source of air pollution.

- Regulatory compliance: Meets all local, state, and federal air quality regulations for VOC emission limits.

- Lower operating costs: The dual-canister design maximizes uptime and minimizes regeneration frequency.

- Simplified logistics: The self-contained skid eliminates the need to transport support equipment to each site.

- Rapid commissioning: Units can be operational in less than a day since no site integration is required.

Technical Specifications

Below are some key technical specifications for the R/bak SR 2000 Series models:

| Parameter | SR 2000 Specification |

|---|---|

| Max Vapor Flow Capacity | 2000 SCFM |

| Carbon Adsorption Capacity | 20,000 lbs per canister |

| Regeneration Gas | Nitrogen (external source) |

| Blower Power | 75 HP |

| Oxidizer Duty Cycle | 12 hours |

| Noise Level | 80 dBA @ 10 ft |

| Length | 24 ft |

| Width | 8 ft |

| Height | 12 ft |

| Weight | 36,000 lbs |

Applications in Oil and Gas Industry

The portable and self-contained nature of the R/bak SR 2000 Series makes it ideal for use at remote well sites and in shale plays where truck loading of condensate and produced water is common. Key applications include:

- Well flowback operations – Capture of VOC vapors during initial flowback of new wells.

- Saltwater disposal – Recovery of vapors when loading trucks with produced water for offsite disposal.

- Condensate stabilization – Capture of natural gas vapors when condensate tanks are loaded out.

- Multi-well pads – Flexibility to move units between wells and pads as truck load-out needs change.

The R/bak SR 2000 Series has been used by leading exploration and production companies across every major shale basin, demonstrating its versatility as portable vapor recovery solution.

Frequently Asked Questions

Here are answers to some common questions about the R/bak SR 2000 Series portable vapor recovery units:

Q: How often does the carbon need to be replaced in the R/bak units?

A: The high adsorption capacity carbon used in the R/bak units can typically last for over a year before needing replacement. The dual canister system maximizes carbon life by allowing continuous operation.

Q: What is the maintenance like on these vapor recovery units?

A: Maintenance is minimal, with just periodic filter changes and inspections needed. The automated operation reduces wear on components. Total maintenance time averages less than one hour per week.

Q: What ventilation or spacing is required around the R/bak units?

A: No special ventilation or spacing is required, allowing flexible placement on crowded well pads. The units contain all vapors and emissions within the system.

Q: How is the captured vapor flow data monitored?

A: The integrated PLC allows real-time monitoring of all vapor flow rates, total recovery volume, and operational metrics. Data can be accessed remotely via cellular network.

Q: What training is required for operators of the R/bak units?

A: Extensive training is not required due to the automated operation. Operators only need basic instruction on periodic maintenance procedures and how to access unit data remotely.

Conclusion

The R/bak SR 2000 Series represents a major leap forward in portable, self-contained vapor recovery technology. With its automated operation, remote monitoring, and rugged skid-mounted design, the R/bak units provide oil and gas producers with a versatile solution to meet air quality regulations and reduce environmental emissions from wellsite loading operations. As regulations expand and well sites become more crowded, the demand for compact, efficient vapor recovery will continue to grow. R/bak is positioned as an innovator and leader in meeting this need through advanced products like the SR 2000 Series.

Leave a Reply