Introduction to QFN and QFP Packages

Quad Flat No-lead (QFN) and Quad Flat Package (QFP) are two of the most commonly used surface-mount package types in modern electronic devices. These packages offer several advantages, including smaller footprints, better thermal and electrical performance, and lower costs compared to traditional through-hole packages.

What is a QFN Package?

A QFN package is a surface-mount package with a leadless design. The package has a flat, square body with exposed pads on the bottom surface for soldering directly to the PCB. QFN packages are available in various sizes, ranging from 1x1mm to 12x12mm, with pin counts ranging from 4 to 100 or more.

What is a QFP Package?

A QFP package is a surface-mount package with leads extending from all four sides of the package body. The leads are bent downwards and outwards, forming a gull-wing shape. QFP packages are available in various sizes, ranging from 4x4mm to 40x40mm, with pin counts ranging from 32 to 256 or more.

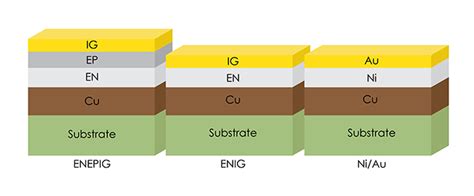

PCB Finishes for QFN and QFP Packages

When designing a PCB for QFN or QFP packages, one crucial factor to consider is the choice of PCB finish. The PCB finish is the final coating applied to the copper pads and traces on the PCB surface, which protects the copper from oxidation and enhances the solderability of the components.

Two of the most popular PCB finishes for QFN and QFP packages are Hot Air Solder Leveling (HASL) and Electroless Nickel Immersion Gold (ENIG).

Hot Air Solder Leveling (HASL)

HASL is a traditional PCB finish that involves dipping the PCB into a molten solder bath and then using hot air to level the solder on the surface. The resulting finish is a thin, uniform layer of solder that covers the copper pads and traces.

Advantages of HASL

- Cost-effective: HASL is one of the most economical PCB finishes available, making it a popular choice for low-cost applications.

- Good solderability: The solder finish provides excellent wettability and solderability, ensuring reliable solder joints between the components and the PCB.

- Durability: HASL finishes are resistant to oxidation and corrosion, providing good protection for the copper surfaces.

Disadvantages of HASL

- Uneven surface: The hot air leveling process can result in an uneven surface, with variations in solder thickness across the PCB. This can cause issues with component placement and soldering, particularly for fine-pitch packages like QFN and QFP.

- Thermal shock: The high temperature of the molten solder bath can cause thermal shock to the PCB, potentially leading to warpage or damage to the substrate.

- Limited shelf life: HASL finishes have a limited shelf life, as the solder surface can oxidize over time, reducing solderability.

Electroless Nickel Immersion Gold (ENIG)

ENIG is a more advanced PCB finish that involves depositing a thin layer of nickel on the copper surfaces, followed by a thin layer of gold. The nickel layer provides a barrier against copper diffusion, while the gold layer protects the nickel from oxidation and enhances solderability.

Advantages of ENIG

- Flat surface: ENIG finishes provide a flat, uniform surface, with minimal variations in thickness across the PCB. This makes it ideal for fine-pitch packages like QFN and QFP, ensuring accurate component placement and reliable soldering.

- Excellent solderability: The gold surface provides excellent wettability and solderability, ensuring strong and reliable solder joints between the components and the PCB.

- Long shelf life: ENIG finishes have a long shelf life, as the gold surface does not oxidize, maintaining good solderability over time.

- Aluminum wire bonding: ENIG is compatible with aluminum wire bonding, making it suitable for applications that require wire bonding, such as chip-on-board (COB) assemblies.

Disadvantages of ENIG

- Higher cost: ENIG is a more expensive PCB finish compared to HASL, due to the additional processing steps and materials involved.

- Black pad: In some cases, the nickel layer can become too thick, leading to a phenomenon called “black pad.” This can cause weak solder joints and reduced reliability.

- Gold embrittlement: If the gold layer is too thick, it can cause embrittlement of the solder joints, leading to cracking and failure under stress.

Comparing HASL and ENIG for QFN and QFP Packages

When choosing between HASL and ENIG for QFN and QFP packages, several factors should be considered, including cost, solderability, surface flatness, and reliability.

| Factor | HASL | ENIG |

|---|---|---|

| Cost | Lower | Higher |

| Solderability | Good | Excellent |

| Surface Flatness | Uneven | Flat |

| Shelf Life | Limited | Long |

| Thermal Shock | Potential Issue | No Issue |

| Aluminum Wire Bonding | Not Compatible | Compatible |

| Black Pad | No Issue | Potential Issue |

| Gold Embrittlement | No Issue | Potential Issue |

Based on these factors, ENIG is generally the preferred choice for QFN and QFP packages, especially for high-density designs with fine-pitch components. The flat surface and excellent solderability of ENIG ensure accurate component placement and reliable solder joints, while the long shelf life and compatibility with aluminum wire bonding make it suitable for a wide range of applications.

However, for low-cost, less demanding applications, HASL may be a more cost-effective option, provided that the uneven surface and limited shelf life do not pose significant issues.

Best Practices for Soldering QFN and QFP Packages

Regardless of the PCB finish chosen, proper soldering techniques are essential for achieving reliable solder joints with QFN and QFP packages. Some best practices include:

- Use a solder stencil: A solder stencil ensures precise and consistent solder paste deposition on the PCB pads, minimizing the risk of bridging or insufficient solder.

- Control solder paste volume: Too much or too little solder paste can lead to soldering defects. Use the appropriate solder paste volume for the package size and pitch.

- Optimize reflow profile: Use a reflow profile that is optimized for the specific package type and PCB finish, ensuring proper solder melting and wetting without causing thermal damage to the components or PCB.

- Use a nitrogen atmosphere: Soldering in a nitrogen atmosphere can help reduce oxidation and improve solder joint quality, particularly for fine-pitch packages like QFN and QFP.

- Inspect solder joints: After soldering, use visual inspection or X-ray inspection to verify the quality of the solder joints, checking for bridging, voids, or other defects.

FAQ

-

Q: Can I use HASL for fine-pitch QFN packages?

A: While HASL can be used for QFN packages, the uneven surface may cause issues with component placement and soldering, particularly for fine-pitch packages. ENIG is generally recommended for fine-pitch QFN packages. -

Q: Is ENIG always the best choice for QFP packages?

A: ENIG is often the preferred choice for QFP packages due to its flat surface and excellent solderability. However, for less demanding applications, HASL may be a more cost-effective option. -

Q: How can I prevent black pad issues with ENIG?

A: To prevent black pad issues, ensure that the nickel layer thickness is well-controlled during the ENIG process. Proper process control and monitoring can help minimize the risk of black pad. -

Q: Can I use ENIG for aluminum wire bonding?

A: Yes, ENIG is compatible with aluminum wire bonding, making it suitable for applications that require wire bonding, such as chip-on-board (COB) assemblies. -

Q: What is the shelf life of HASL and ENIG finishes?

A: HASL finishes have a limited shelf life, typically around 6 to 12 months, due to the potential for oxidation of the solder surface. ENIG finishes have a much longer shelf life, often exceeding 12 months, as the gold surface does not oxidize.

Conclusion

When selecting a PCB finish for QFN and QFP packages, both HASL and ENIG have their advantages and disadvantages. ENIG is generally the preferred choice for fine-pitch packages, offering a flat surface, excellent solderability, and long shelf life. However, HASL may be a more cost-effective option for less demanding applications.

Ultimately, the choice between HASL and ENIG depends on the specific requirements of the application, including cost, density, reliability, and compatibility with other processes like wire bonding. By understanding the characteristics of each finish and following best practices for soldering, designers can ensure reliable and high-quality solder joints for QFN and QFP packages.

Leave a Reply