Understanding OSP PCB Finish and Its Common Issues

Organic Solderability Preservative (OSP) is a popular surface finish for printed circuit boards (PCBs) due to its cost-effectiveness and environmental friendliness. However, OSP PCB finish can sometimes encounter various issues that affect the solderability and reliability of the PCBs. In this article, we will discuss the common problems associated with OSP PCB finish and how to address them.

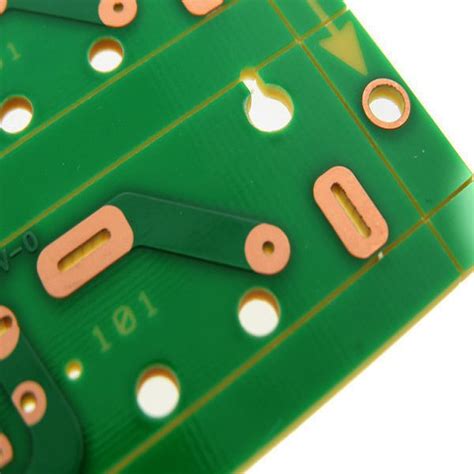

What is OSP PCB Finish?

OSP is a chemical coating applied to the copper pads on a PCB to prevent oxidation and maintain solderability. The coating is typically composed of organic compounds, such as benzimidazole or benzotriazole, which form a protective layer on the copper surface. OSP is an attractive choice for PCB manufacturers because it is relatively inexpensive, easy to apply, and does not require additional processing steps like other surface finishes such as ENIG or HASL.

Advantages of OSP PCB Finish

- Cost-effective compared to other surface finishes

- Environmentally friendly due to the absence of lead and other hazardous materials

- Provides good solderability for a limited time

- Suitable for fine-pitch components and high-density PCB designs

- Easily reworkable and repairable

Common Issues with OSP PCB Finish

Despite its advantages, OSP PCB finish can encounter several problems that affect the quality and reliability of the PCBs. Some of the most common issues include:

1. Poor Wetting

Poor wetting occurs when the solder does not adequately spread and adhere to the copper pads during the soldering process. This can result in weak solder joints, reduced electrical conductivity, and potential reliability issues. Poor wetting can be caused by several factors, such as:

- Contamination of the OSP coating due to improper handling or storage

- Excessive OSP coating thickness, which can hinder solder flow

- Inadequate preheating or soldering temperature

- Incompatible solder paste or flux

To address poor wetting issues, consider the following solutions:

- Ensure proper handling and storage of OSP-coated PCBs to prevent contamination

- Optimize the OSP coating thickness to ensure adequate solder flow

- Adjust preheating and soldering temperatures according to the solder paste manufacturer’s recommendations

- Use compatible solder paste and flux designed for OSP surface finish

2. Copper Leaching

Copper leaching is a phenomenon where the copper from the PCB pads dissolves into the molten solder during the soldering process. This can lead to the formation of copper-tin intermetallic compounds (IMCs), which can cause brittle solder joints and reduced reliability. Copper leaching is more prominent in OSP PCB finish compared to other surface finishes due to the thin nature of the OSP coating.

To minimize copper leaching, consider the following measures:

- Use a nitrogen atmosphere during soldering to reduce oxidation and copper dissolution

- Optimize the soldering profile to minimize the time the PCB is exposed to high temperatures

- Select solder alloys with lower copper solubility, such as SAC305 or SN100C

- Apply a thicker OSP coating to provide better protection against copper leaching

3. OSP Coating Degradation

OSP coating can degrade over time due to exposure to air, moisture, and elevated temperatures. The degradation of the OSP coating can lead to reduced solderability, poor wetting, and potential reliability issues. The shelf life of OSP-coated PCBs is typically shorter compared to other surface finishes, ranging from 3 to 12 months, depending on the storage conditions.

To extend the shelf life of OSP-coated PCBs and prevent coating degradation, follow these guidelines:

- Store OSP-coated PCBs in a controlled environment with low humidity and temperature

- Use moisture barrier bags with desiccants to protect the PCBs from moisture ingress

- Avoid exposing OSP-coated PCBs to high temperatures during storage and transportation

- Process OSP-coated PCBs within the recommended shelf life to ensure optimal solderability

4. Solder Mask Compatibility

Some solder mask materials may not be compatible with OSP coating, leading to adhesion issues or chemical reactions that can affect the solderability and reliability of the PCBs. Incompatible solder mask can cause the OSP coating to delaminate or degrade, exposing the copper pads to oxidation and contamination.

To ensure compatibility between solder mask and OSP coating, consider the following:

- Select solder mask materials that are specifically designed for use with OSP surface finish

- Conduct compatibility testing between the solder mask and OSP coating to verify adhesion and stability

- Follow the solder mask manufacturer’s recommendations for curing and post-curing processes

- Consult with your PCB manufacturer or solder mask supplier for guidance on compatible materials

Best Practices for Working with OSP PCB Finish

To minimize the occurrence of OSP PCB finish issues and ensure optimal solderability and reliability, follow these best practices:

- Handle OSP-coated PCBs with care to prevent contamination and damage to the coating

- Store OSP-coated PCBs in a controlled environment with low humidity and temperature

- Process OSP-coated PCBs within the recommended shelf life to ensure optimal solderability

- Optimize the soldering profile and parameters according to the solder paste manufacturer’s recommendations

- Use compatible solder mask materials and conduct compatibility testing

- Consider using nitrogen atmosphere during soldering to reduce oxidation and copper leaching

- Inspect the solder joints for any defects or anomalies and perform necessary rework or repair

- Conduct regular quality control checks to monitor the solderability and reliability of OSP-coated PCBs

By understanding the common issues associated with OSP PCB finish and implementing these best practices, you can minimize the occurrence of problems and ensure the production of high-quality, reliable PCBs.

Frequently Asked Questions (FAQ)

-

Q: What is the typical shelf life of OSP-coated PCBs?

A: The shelf life of OSP-coated PCBs can vary depending on the storage conditions, but it typically ranges from 3 to 12 months. It is recommended to process OSP-coated PCBs within the specified shelf life to ensure optimal solderability. -

Q: Can OSP-coated PCBs be reworked or repaired?

A: Yes, OSP-coated PCBs can be reworked or repaired. However, it is essential to use compatible soldering materials and techniques to avoid damaging the OSP coating or causing further issues. Consult with your PCB manufacturer or repair service provider for guidance on the appropriate rework or repair procedures. -

Q: How can I prevent copper leaching in OSP-coated PCBs?

A: To minimize copper leaching in OSP-coated PCBs, you can use a nitrogen atmosphere during soldering, optimize the soldering profile to reduce exposure to high temperatures, select solder alloys with lower copper solubility, and apply a thicker OSP coating for better protection. -

Q: What should I do if I encounter poor wetting issues with OSP-coated PCBs?

A: If you experience poor wetting issues with OSP-coated PCBs, ensure proper handling and storage to prevent contamination, optimize the OSP coating thickness, adjust preheating and soldering temperatures, and use compatible solder paste and flux designed for OSP surface finish. -

Q: Can I use any solder mask material with OSP coating?

A: Not all solder mask materials are compatible with OSP coating. It is essential to select solder mask materials that are specifically designed for use with OSP surface finish and conduct compatibility testing to verify adhesion and stability. Consult with your PCB manufacturer or solder mask supplier for guidance on compatible materials.

Conclusion

OSP PCB finish is a popular choice for PCB manufacturers due to its cost-effectiveness and environmental friendliness. However, it is essential to be aware of the common issues associated with OSP, such as poor wetting, copper leaching, coating degradation, and solder mask compatibility. By understanding these problems and implementing best practices for handling, storage, and processing of OSP-coated PCBs, you can minimize the occurrence of issues and ensure the production of high-quality, reliable PCBs.

Leave a Reply