Introduction to Flip Chip Resistors

Flip chip resistors are a type of surface mount resistor that offer superior performance compared to traditional resistor packages. They are designed with the resistive element facing down, which allows for better thermal dissipation and improved electrical characteristics. This unique construction makes flip chip resistors ideal for high-frequency and high-power applications.

Advantages of Flip Chip Resistors

- Improved thermal dissipation

- Lower parasitic inductance and capacitance

- Better high-frequency performance

- Smaller package size

- Higher power handling capability

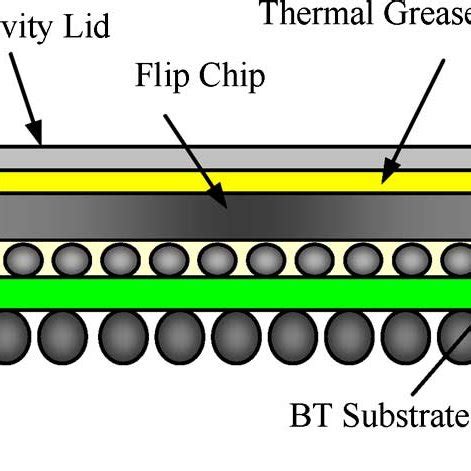

Flip Chip Resistor Construction

Resistive Element

The resistive element in a flip chip resistor is typically made of thin-film or thick-film materials, such as nickel-chromium (NiCr) or ruthenium oxide (RuO2). These materials are deposited onto a ceramic substrate using sputtering or screen printing techniques. The thickness and composition of the resistive layer determine the resistance value and temperature coefficient of the resistor.

Substrate Material

Alumina (Al2O3) is the most common substrate material used in flip chip resistors due to its excellent thermal conductivity and mechanical stability. Other substrate materials, such as silicon nitride (Si3N4) and aluminum nitride (AlN), may be used for specialized applications that require higher thermal conductivity or better dielectric properties.

Terminations

Flip chip resistors use solder bumps or gold stud bumps for terminations, which are directly connected to the resistive element. These terminations provide a low-resistance, high-current connection between the resistor and the circuit board. The bumps also act as a mechanical support for the resistor, ensuring a reliable and stable connection.

Flip Chip Resistor Performance Characteristics

Temperature Coefficient of Resistance (TCR)

The temperature coefficient of resistance (TCR) is a measure of how much the resistance value changes with temperature. Flip chip resistors typically have a low TCR, ranging from ±25 ppm/°C to ±100 ppm/°C, depending on the resistive material and manufacturing process. A low TCR ensures stable performance over a wide temperature range.

Power Rating

Flip chip resistors have a higher power rating compared to traditional surface mount resistors due to their improved thermal dissipation. The power rating depends on the resistor size and the substrate material. Typical power ratings range from 0.1 W to 1 W for standard flip chip resistors, with some specialized designs capable of handling up to 5 W.

Frequency Response

The low parasitic inductance and capacitance of flip chip resistors make them suitable for high-frequency applications. They exhibit excellent frequency response, with minimal impedance variation up to several gigahertz (GHz). This characteristic is particularly important in RF and microwave circuits, where consistent impedance is critical for optimal performance.

Noise Performance

Flip chip resistors have low current noise and voltage noise, thanks to their compact size and low parasitic effects. This makes them ideal for use in low-noise amplifiers, sensors, and other noise-sensitive applications.

Applications of Flip Chip Resistors

RF and Microwave Circuits

Flip chip resistors are widely used in RF and microwave circuits, such as power amplifiers, low-noise amplifiers, and mixers. Their low parasitic inductance and capacitance ensure consistent impedance matching and minimal signal distortion at high frequencies.

Power Electronics

The high power handling capability and excellent thermal dissipation of flip chip resistors make them suitable for power electronic applications, such as voltage regulators, power converters, and motor drives. They can be used as current sensing resistors, ballast resistors, or snubber resistors in these circuits.

Precision Analog Circuits

Flip chip resistors are used in precision analog circuits, such as data converters, instrumentation amplifiers, and reference voltage sources. Their low TCR and low noise characteristics ensure accurate and stable performance over a wide temperature range.

Automotive Electronics

The automotive industry increasingly relies on flip chip resistors for their reliability and performance in harsh environments. They are used in various automotive applications, such as engine control units, sensors, and infotainment systems.

Flip Chip Resistor Manufacturing Process

Thin-Film Deposition

Thin-film flip chip resistors are manufactured by depositing a thin layer of resistive material, typically NiCr, onto a ceramic substrate using sputtering or evaporation techniques. The thickness of the resistive layer is precisely controlled to achieve the desired resistance value and TCR.

Thick-Film Screen Printing

Thick-film flip chip resistors are produced by screen printing a paste containing resistive material, such as RuO2, onto a ceramic substrate. The paste is then fired at high temperatures to form a stable resistive layer. Thick-film resistors offer higher power handling capability and better high-temperature performance compared to thin-film resistors.

Laser Trimming

After the resistive layer is deposited or printed, the resistors are laser trimmed to achieve the desired resistance value with high precision. Laser trimming involves selectively removing a portion of the resistive material using a high-energy laser beam. This process allows for tight tolerance control and excellent stability over time.

Bump Formation

Solder bumps or gold stud bumps are formed on the resistor terminations using various methods, such as electroplating, stencil printing, or ball bonding. These bumps provide a reliable and low-resistance connection between the resistor and the circuit board.

Packaging and Testing

Finally, the flip chip resistors are packaged and tested to ensure they meet the specified performance requirements. Packaging options include wafer-level packaging (WLP) and chip-scale packaging (CSP), which offer a small footprint and improved thermal dissipation.

Future Trends in Flip Chip Resistor Technology

Advanced Materials

Researchers are continuously exploring new resistive materials and substrate materials to improve the performance of flip chip resistors. For example, graphene-based resistive layers have shown promise in achieving ultra-low TCR and high power handling capability.

3D Integration

The development of 3D integration technologies, such as through-silicon vias (TSVs) and stacked die packaging, is expected to enable the integration of flip chip resistors with other components, such as capacitors and inductors, in a single package. This will lead to more compact and efficient electronic systems.

Additive Manufacturing

Additive manufacturing techniques, such as 3D printing, are being investigated for the fabrication of flip chip resistors. These methods have the potential to reduce manufacturing costs, improve design flexibility, and enable the creation of complex resistor geometries.

Frequently Asked Questions (FAQ)

1. What is the main advantage of flip chip resistors over traditional surface mount resistors?

Flip chip resistors offer superior thermal dissipation and improved electrical characteristics, such as lower parasitic inductance and capacitance, compared to traditional surface mount resistors. This makes them ideal for high-frequency and high-power applications.

2. What materials are commonly used for the resistive element in flip chip resistors?

The most common materials used for the resistive element in flip chip resistors are nickel-chromium (NiCr) for thin-film resistors and ruthenium oxide (RuO2) for thick-film resistors. These materials offer stable resistance values and low temperature coefficients.

3. How does the flip chip construction improve thermal dissipation?

In a flip chip resistor, the resistive element is facing down and directly connected to the substrate through the solder bumps or gold stud bumps. This configuration allows for better heat transfer from the resistive element to the substrate and, subsequently, to the circuit board, improving overall thermal dissipation.

4. What is the typical power rating of flip chip resistors?

The power rating of flip chip resistors depends on the resistor size and the substrate material. Typical power ratings range from 0.1 W to 1 W for standard flip chip resistors, with some specialized designs capable of handling up to 5 W.

5. What are the main applications of flip chip resistors?

Flip chip resistors are widely used in various applications, including:

- RF and microwave circuits, such as power amplifiers, low-noise amplifiers, and mixers

- Power electronics, such as voltage regulators, power converters, and motor drives

- Precision analog circuits, such as data converters, instrumentation amplifiers, and reference voltage sources

- Automotive electronics, such as engine control units, sensors, and infotainment systems

| Characteristic | Flip Chip Resistors | Traditional Surface Mount Resistors |

|---|---|---|

| Thermal dissipation | Excellent | Good |

| Parasitic inductance and capacitance | Low | Moderate |

| High-frequency performance | Excellent | Good |

| Power handling capability | High | Moderate |

| Package size | Small | Larger |

In conclusion, flip chip resistors offer numerous advantages over traditional surface mount resistors, making them the preferred choice for high-performance electronic applications. With their superior thermal dissipation, low parasitic effects, and excellent high-frequency performance, flip chip resistors are set to play an increasingly important role in the development of advanced electronic systems. As research into new materials and manufacturing processes continues, we can expect to see further improvements in the performance and reliability of flip chip resistors in the coming years.

Leave a Reply