Introduction to Flexible Printed Circuits

Flexible printed circuits (FPCs), also known as flex circuits or flexible printed circuit boards (PCBs), have revolutionized the electronics industry by providing a versatile and reliable solution for interconnecting electronic components in a wide range of applications. These circuits are designed to bend, fold, and twist without compromising their electrical performance or structural integrity. In this comprehensive article, we will explore the types of flexible printed circuits, their benefits, and their diverse applications across various industries.

What are Flexible Printed Circuits?

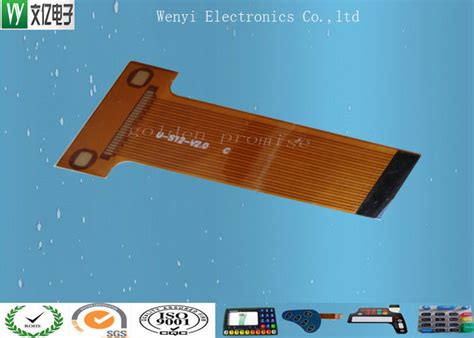

Flexible printed circuits are a type of PCB that consists of a thin, flexible substrate made of materials such as polyimide or polyester. These substrates are laminated with conductive traces, typically copper, to create the desired circuit pattern. FPCs can be single-sided, double-sided, or multi-layered, depending on the complexity and requirements of the application.

The key characteristic of FPCs is their ability to flex and conform to various shapes and configurations. This flexibility enables designers to create compact, lightweight, and space-efficient electronic devices that can withstand repeated bending and folding without damaging the circuit or components.

Types of Flexible Printed Circuits

There are several types of flexible printed circuits, each designed to cater to specific requirements and applications. Let’s explore the most common types of FPCs:

Single-Sided Flexible Circuits

Single-sided flexible circuits have conductive traces on only one side of the flexible substrate. They are the simplest and most cost-effective type of FPC, suitable for applications with lower complexity and fewer interconnections. Single-sided FPCs are commonly used in consumer electronics, such as keyboards, displays, and battery packs.

Double-Sided Flexible Circuits

Double-sided flexible circuits have conductive traces on both sides of the flexible substrate. They offer higher circuit density and more efficient use of space compared to single-sided FPCs. Double-sided FPCs are widely used in applications that require more complex routing and interconnections, such as medical devices, automotive electronics, and industrial equipment.

Multi-Layer Flexible Circuits

Multi-layer flexible circuits consist of three or more conductive layers separated by insulating layers. They provide the highest level of circuit density and functionality among FPCs. Multi-layer FPCs are used in demanding applications that require a large number of interconnections and signal routing, such as aerospace systems, high-end consumer electronics, and telecommunications equipment.

Rigid-Flex Circuits

Rigid-flex circuits combine the benefits of both rigid PCBs and flexible circuits. They consist of rigid PCB sections connected by flexible circuit sections, allowing for three-dimensional packaging and improved reliability. Rigid-flex circuits are commonly used in applications that require a mix of stable and flexible connections, such as wearable devices, robotics, and military equipment.

Benefits of Flexible Printed Circuits

Flexible printed circuits offer numerous benefits over traditional rigid PCBs. Let’s explore some of the key advantages of using FPCs in electronic devices:

Flexibility and Durability

The most significant benefit of FPCs is their flexibility. They can bend, fold, and twist without breaking or losing their electrical properties. This flexibility enables designers to create compact and lightweight devices that can fit into tight spaces and conform to complex shapes. Moreover, FPCs are highly durable and can withstand repeated flexing and stress, making them suitable for applications that require frequent movement or exposure to harsh environments.

Space and Weight Reduction

FPCs allow for significant space and weight reduction in electronic devices. By eliminating the need for bulky connectors and wires, FPCs enable designers to create more compact and lightweight products. This is particularly important in applications where size and weight are critical factors, such as portable devices, aerospace systems, and medical implants.

Improved Signal Integrity

Flexible printed circuits offer improved signal integrity compared to traditional wiring methods. The close proximity of the conductive traces and the Controlled impedance of the circuit reduce signal noise, crosstalk, and electromagnetic interference (EMI). This results in cleaner and more reliable signal transmission, which is crucial in high-speed and sensitive applications.

Enhanced Reliability

FPCs contribute to enhanced reliability in electronic devices. By eliminating the need for manual wiring and soldering, FPCs reduce the risk of human error and improve the consistency of the connections. Additionally, the flexible nature of FPCs allows for better stress distribution and reduced strain on components, minimizing the chances of failure due to mechanical stress or vibration.

Cost-Effectiveness

Although the initial cost of FPCs may be higher than rigid PCBs, they offer long-term cost-effectiveness in many applications. The reduced assembly time, fewer components, and improved reliability contribute to lower manufacturing and maintenance costs. Moreover, the ability to integrate multiple functions into a single FPC reduces the overall part count and simplifies the supply chain management.

Applications of Flexible Printed Circuits

Flexible printed circuits find applications in a wide range of industries due to their versatility, reliability, and performance benefits. Let’s explore some of the key application areas of FPCs:

Consumer Electronics

FPCs are extensively used in consumer electronics, such as smartphones, tablets, laptops, and wearable devices. They enable thin and lightweight designs, improved durability, and enhanced functionality. FPCs are commonly found in display modules, touch screens, cameras, and battery connections in these devices.

Medical Devices

The medical industry has greatly benefited from the adoption of FPCs. Flexible circuits are used in various medical devices, including implantable devices, diagnostic equipment, and patient monitoring systems. FPCs enable miniaturization, biocompatibility, and reliable performance in these critical applications. Examples include pacemakers, hearing aids, and endoscopic devices.

Automotive Electronics

FPCs play a crucial role in automotive electronics, where reliability and durability are paramount. They are used in various applications, such as instrument clusters, infotainment systems, sensors, and wiring harnesses. FPCs offer space savings, weight reduction, and improved signal integrity in these demanding environments.

Aerospace and Defense

The aerospace and defense industries rely on FPCs for their high-performance and reliability requirements. Flexible circuits are used in avionics systems, satellite communications, radar equipment, and military vehicles. FPCs offer weight reduction, space savings, and improved signal integrity, which are critical factors in these applications.

Industrial Equipment

FPCs are increasingly used in industrial equipment, such as robots, automation systems, and process control devices. They offer flexibility, durability, and reliable performance in harsh industrial environments. FPCs enable compact designs, improved connectivity, and reduced maintenance costs in these applications.

Frequently Asked Questions (FAQs)

-

What materials are commonly used for the flexible substrate in FPCs?

The most common materials used for the flexible substrate in FPCs are polyimide (PI) and polyester (PET). Polyimide is known for its excellent thermal stability, chemical resistance, and mechanical strength, making it suitable for high-performance applications. Polyester is a more cost-effective option and is commonly used in consumer electronics and less demanding applications. -

Can FPCs be used in high-temperature environments?

Yes, FPCs can be designed to withstand high-temperature environments. The choice of substrate material and the construction of the FPC play a crucial role in determining its temperature resistance. Polyimide-based FPCs, for example, can typically operate in temperatures ranging from -40°C to +200°C, making them suitable for applications in automotive, aerospace, and industrial sectors. -

How are components mounted on flexible printed circuits?

Components can be mounted on FPCs using various methods, depending on the application requirements and the type of components. Surface mount technology (SMT) is commonly used, where components are directly soldered onto the surface of the FPC. Through-hole mounting, where components are inserted into holes drilled in the FPC and soldered, is another option. Additionally, conductive adhesives and z-AXIs conductive tapes can be used for certain applications. -

What are the challenges in designing flexible printed circuits?

Designing FPCs comes with several challenges that need to be considered. Some of the key challenges include: - Ensuring proper bend radius and flexibility without compromising the circuit integrity

- Managing the thermal expansion and contraction of the materials during operation

- Maintaining signal integrity and minimizing electromagnetic interference (EMI)

- Selecting the appropriate materials and adhesives for the specific application requirements

-

Optimizing the circuit layout and component placement for reliability and manufacturability

-

How do I choose the right type of flexible printed circuit for my application?

Choosing the right type of FPC depends on several factors, including: - The complexity and density of the circuit

- The space and weight constraints of the application

- The environmental conditions and operating temperature range

- The required flexibility and bend radius

- The budget and production volume

It is recommended to consult with an experienced FPC manufacturer, such as RAYPCB, to discuss your specific requirements and determine the most suitable type of FPC for your application.

Conclusion

Flexible printed circuits have become an essential component in the electronics industry, enabling the development of compact, lightweight, and reliable devices across various sectors. With their flexibility, durability, and performance benefits, FPCs offer designers and engineers a versatile solution for interconnecting electronic components in challenging environments.

From consumer electronics to medical devices, automotive electronics to aerospace systems, FPCs have proven their value in enhancing functionality, reliability, and cost-effectiveness. As technology continues to advance and the demand for smaller and more complex devices grows, the role of flexible printed circuits will only become more prominent.

RAYPCB, a leading manufacturer of high-quality flexible printed circuits, is committed to providing innovative and reliable FPC solutions to meet the evolving needs of its customers. With state-of-the-art manufacturing facilities, experienced engineers, and a focus on quality and customer satisfaction, RAYPCB is well-positioned to support the growing demand for flexible printed circuits in the electronics industry.

| Type of FPC | Characteristics | Typical Applications |

|---|---|---|

| Single-Sided FPC | – Conductive traces on one side of the substrate – Simple and cost-effective |

– Consumer electronics (keyboards, displays, battery packs) |

| Double-Sided FPC | – Conductive traces on both sides of the substrate – Higher circuit density and space efficiency |

– Medical devices – Automotive electronics – Industrial equipment |

| Multi-Layer FPC | – Three or more conductive layers separated by insulating layers – Highest circuit density and functionality |

– Aerospace systems – High-end consumer electronics – Telecommunications equipment |

| Rigid-Flex Circuits | – Combination of rigid PCB sections and flexible circuit sections – Enables 3D packaging and improved reliability |

– Wearable devices – Robotics – Military equipment |

Table 1: Comparison of different types of flexible printed circuits and their typical applications

Leave a Reply