Key Features of BISCO’s RS-800 FR Series

High Flame Resistance for Safety

The BISCO RS-800 FR series features flame resistant silicone rubber that meets the stringent UL 94 V-0 flame rating. This means it offers excellent resistance to catching fire and spreading flames, making it ideal for applications where safety is paramount.

Wide Service Temperature Range

With a service temperature range of -55°C to 260°C, RS-800 can withstand exposure to extreme heat while maintaining its flexibility and protective properties. This makes it suitable for demanding environments.

Excellent Electrical Insulation

With a dielectric strength of over 500V/mil, the FR series provides reliable insulation for electrical components and withstands transient voltage spikes. This helps prevent short circuits and potential fire hazards.

Good Physical Properties

The RS-800 retains the typical properties of silicone like weather resistance, low compression set, and flexibility over a wide temperature range. This versatility allows it to be used in many types of industrial applications.

Typical Properties of RS-800 FR Series

| Property | Value | Test Method |

|---|---|---|

| Durometer (Shore A) | 60 | ASTM D2240 |

| Tensile Strength | 1000 psi | ASTM D412 |

| Elongation | 500% | ASTM D412 |

| Tear Strength | 200 ppi | ASTM D624 |

| Specific Gravity | 1.15 | ASTM D297 |

| UL 94 Flame Rating | V-0 | UL 94 |

The RS-800 series offers an optimal balance of flame resistance, temperature performance, and physical properties.

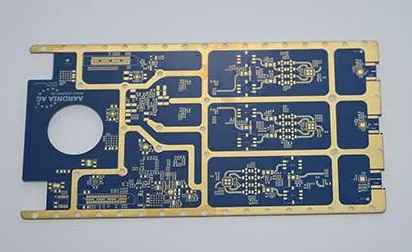

Applications of RS-800 FR Silicone Rubber

The flame resistant qualities and wide service temperature range make RS-800 suitable for:

- Wire and cable insulation

- Molded parts near heat sources

- Industrial hoses and tubing

- Gaskets and seals in extreme environments

- Vibration dampening components

- Connectors and assembles requiring UL 94 V-0 rating

RS-800’s flexible nature allows it to be fabricated into many shapes using extrusion, molding, or calendering processes. This versatility expands its use across industries.

Key Questions About RS-800 FR Silicone

What types of environments can RS-800 withstand?

With a wide service temperature range and UL 94 V-0 rating, RS-800 can withstand exposure to extreme heat, flames, corrosive chemicals, and weathering. It’s well suited for harsh industrial environments.

Does RS-800 require special handling or storage?

RS-800 can be handled and stored using typical methods for silicone rubber. Keeping materials clean and avoiding contamination is recommended.

What processing methods can be used with RS-800?

RS-800 can be extruded into hoses or profiles, molded into parts and seals, or calendered into sheets using standard silicone rubber processing techniques.

Does RS-800 require post-cure for best results?

Post-curing at 150-200°C for 1-2 hours is recommended after molding to yield optimal physical properties. Extruded profiles can often be used without post-cure.

What regulations and standards does RS-800 comply with?

RS-800 meets UL 94 V-0 flame rating, various cable burn specs, and complies with many flame resistance standards around the world, like IEC 60684, ASTM D7840, etc.

RS-800 offers an optimal balance of flame resistance, temperature performance, and physical properties. Contact BISCO today to see how our RS-800 FR series can meet your application needs while upholding stringent safety standards.

Leave a Reply