An Overview of Rogers curamik Power Plus Substrates

Rogers curamik Power Plus substrates are high-performance laminates designed for power electronic applications. They offer excellent thermal conductivity and electrical insulation properties, making them ideal for use in power modules and other demanding power systems.

Some key features of Rogers curamik Power Plus include:

High thermal conductivity

The Power Plus substrates have thermal conductivity ranging from 1.7 – 4.5 W/mK. This allows efficient heat dissipation from power devices.

Excellent dielectric strength

The dielectric strength is >8 kV/mm, enabling reliable electrical insulation even at high voltages.

Low thermal expansion

With a CTE of ~7 ppm/K, the thermal expansion is well-matched to common semiconductor materials like Si and SiC. This minimizes stresses during thermal cycling.

Good thermal shock resistance

The substrates can reliably withstand rapid temperature changes during operation and cycling.

Flexible circuit design

Rogers curamik Power Plus is available in different material configurations including Cu-AlN, Cu-Al2O3, and Al-SiC. This allows selecting the optimal setup for each application.

Typical Applications of Rogers curamik Power Plus

The unique material properties of Rogers curamik Power Plus make them suitable for the following types of high-power and high-temperature applications:

- Power modules and packages

- Traction inverters and converters

- Wind and solar power converters

- Industrial drives and robotics

- Power supplies and chargers

- Hybrid and electric vehicle power electronics

- Aerospace and defense electronics

The substrates are commonly used as the baseplate, substrate, or heat spreader in these applications. The table below summarizes some of the key applications and components.

| Application | Typical Components |

|---|---|

| Power modules | IGBTs, MOSFETs, diodes |

| Inverters | AC-DC, DC-AC, DC-DC |

| Motor drives | IGBT modules, capacitors |

| Chargers | Rectifiers, converters |

| Aerospace electronics | Radars, controls, actuators |

Key Benefits of Using Rogers curamik Power Plus

Some of the major benefits of selecting Rogers curamik Power Plus substrates include:

- Lower junction temperatures – The high thermal conductivity enables efficient heat extraction from the power devices. This improves reliability and increases power density.

- Reduced thermal stresses – The matched CTE minimizes thermal stresses during operation and thermal cycling. This improves long-term reliability.

- High-temperature capability – The substrates can operate at temperatures exceeding 400°C, enabling high-temperature applications.

- High voltage insulation – The excellent dielectric strength allows using the substrates in high voltage designs > 1 kV.

- Design flexibility – Multiple material configurations provide flexibility to optimize for thermal, electrical, or mechanical needs.

- Light weight – The ceramic-based composites are lighter than metal substrates while providing equal or better performance. This helps reduce weight in applications like aerospace.

By leveraging these benefits, Rogers curamik Power Plus substrates enable smaller, lighter, and more reliable power electronic systems.

Frequently Asked Questions

What are some example module and package types that use Rogers curamik Power Plus?

Some common package types that utilize Rogers curamik Power Plus include IGBT modules, MOSFET modules, diode modules, stacked power modules, 3D integrated modules, and other emerging package types like embedded power modules. These packages are used extensively in power electronic systems across industries.

How does Rogers curamik Power Plus compare with other ceramic substrate materials like AlN and Al2O3?

Compared to AlN and Al2O3, Rogers curamik Power Plus offers higher thermal conductivity while maintaining excellent electrical insulation. The composites layered construction also provides better thermal shock resistance. Power Plus combines the benefits of both ceramics and metal into an optimal substrate for power electronics.

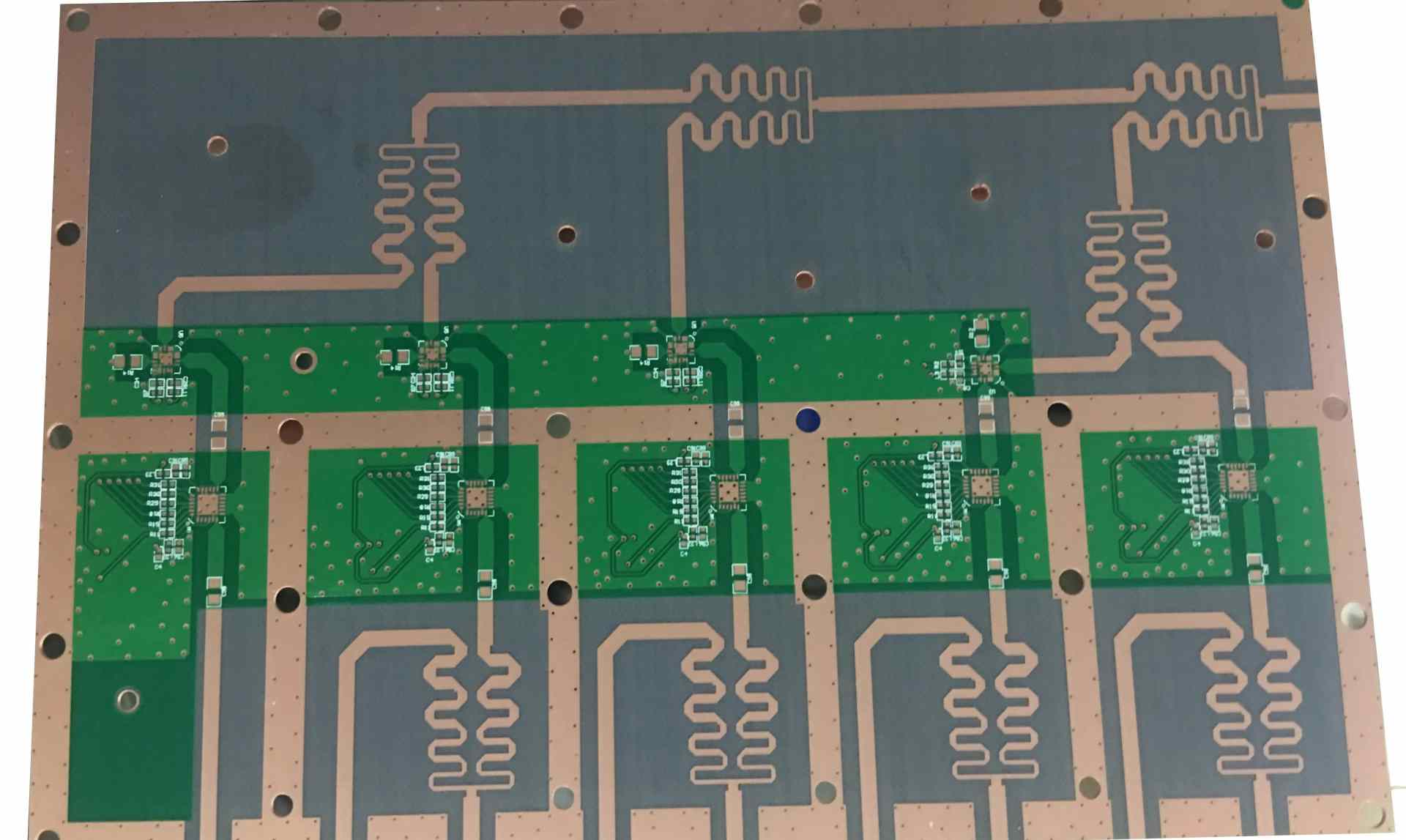

Can Rogers curamik Power Plus substrates be used at high frequencies?

Yes, the low dielectric loss and high resistivity of Rogers curamik Power Plus make them suitable for high frequency applications up to the RF range. They are commonly used as substrates in radar and communications electronics operating at microwave frequencies.

What are some common metal baseplate materials used with Rogers curamik Power Plus?

Some standard baseplate materials paired with Rogers curamik Power Plus include copper, aluminum silicon carbide (AlSiC), and aluminum (Al). This allows selecting the optimal baseplate in terms of thermal and mechanical needs.

Are Rogers curamik Power Plus substrates RoHS compliant?

Yes, Rogers curamik Power Plus substrates meet RoHS requirements for electronics. They do not contain any hazardous substances banned under RoHS.

Leave a Reply