Introduction to PCB Technologies in China

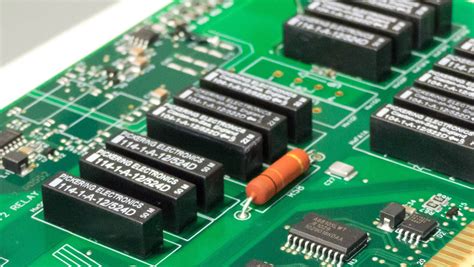

China has become a global leader in the production of printed circuit boards (PCBs), with a vast array of technologies and capabilities. The country’s PCB industry has grown rapidly over the past few decades, driven by increasing demand for electronic products and the development of advanced manufacturing processes. In this article, we will explore the large ASU PCB copy board and set of technologies in China, focusing on the key players, trends, and innovations shaping the industry.

Overview of China’s PCB Industry

China’s PCB industry has experienced tremendous growth since the 1990s, with the country now accounting for over 50% of global PCB production. The industry encompasses a wide range of technologies, including:

- Single-sided and double-sided PCBs

- Multi-layer PCBs

- Flexible and rigid-flex PCBs

- High-density interconnect (HDI) PCBs

- Embedded PCBs

- IC substrate and packaging substrates

The table below shows the market share of different PCB technologies in China:

| PCB Technology | Market Share |

|---|---|

| Multi-layer PCBs | 45% |

| Double-sided PCBs | 25% |

| HDI PCBs | 15% |

| Flexible and rigid-flex PCBs | 10% |

| Others (single-sided, embedded, IC substrate, etc.) | 5% |

Key Players in China’s PCB Industry

Several major companies dominate the PCB industry in China, including:

- Zhen Ding Technology Holding Limited (ZDT): ZDT is the largest PCB manufacturer in China and the third-largest globally. The company specializes in the production of high-end PCBs for applications in smartphones, tablets, and other consumer electronics.

- Shennan Circuits Co., Ltd. (SCC): SCC is a leading manufacturer of multi-layer and HDI PCBs, serving customers in the telecommunications, automotive, and consumer electronics industries.

- Unimicron Technology Corp.: Unimicron is a Taiwanese company with significant operations in China. The company produces a wide range of PCBs, including multi-layer, HDI, and flexible PCBs for applications in mobile devices, automotive electronics, and industrial equipment.

- Wus Printed Circuit (Kunshan) Co., Ltd.: Wus is a subsidiary of the Taiwanese company Wus Printed Circuit Co., Ltd. The company focuses on the production of multi-layer and HDI PCBs for the telecommunications, automotive, and consumer electronics markets.

Advanced PCB Technologies in China

High-Density Interconnect (HDI) PCBs

HDI PCBs are characterized by their fine line width and spacing, small via sizes, and high connection pad density. These features enable the miniaturization of electronic devices and improve signal integrity. China has made significant progress in the development and production of HDI PCBs, with several companies offering advanced HDI solutions:

- Shenzhen Kinwong Electronic Co., Ltd.: Kinwong is a leading provider of HDI PCBs, offering solutions with line width/spacing down to 30/30 µm and via diameters as small as 50 µm.

- Avary Holding (Shenzhen) Co., Ltd.: Avary specializes in the production of HDI PCBs for mobile devices, automotive electronics, and medical equipment. The company’s HDI technology includes fine line width/spacing (40/40 µm) and laser-drilled microvias.

Flexible and Rigid-Flex PCBs

Flexible and rigid-flex PCBs are increasingly used in applications that require high reliability, flexibility, and compact packaging. Chinese companies have invested heavily in the development of these technologies, with several players offering advanced flexible and rigid-flex PCB solutions:

- Flexium Interconnect Inc.: Flexium is a Taiwanese company with manufacturing facilities in China. The company specializes in the production of flexible and rigid-flex PCBs for applications in mobile devices, wearables, and automotive electronics.

- Zhuhai Smartech Electronics Co., Ltd.: Smartech is a leading manufacturer of flexible and rigid-flex PCBs in China, serving customers in the consumer electronics, automotive, and medical device industries. The company offers a range of flexible circuit technologies, including single-sided, double-sided, and multi-layer flexible PCBs.

Embedded PCBs

Embedded PCBs integrate passive and active components within the PCB substrate, enabling higher component density and improved electrical performance. Several Chinese companies have developed advanced embedded PCB technologies:

- Shenzhen Suntak Circuit Technology Co., Ltd.: Suntak is a pioneer in the development of embedded PCB technologies in China. The company offers a range of embedded solutions, including embedded resistors, capacitors, and active components.

- Elec & Eltek International Company Limited: Elec & Eltek is a Hong Kong-based company with manufacturing facilities in China. The company specializes in the production of high-end PCBs, including embedded PCBs for applications in telecommunications, automotive electronics, and medical devices.

Trends and Innovations in China’s PCB Industry

5G and High-Frequency PCBs

The rollout of 5G networks and the increasing demand for high-frequency applications have driven the development of advanced PCB technologies in China. Companies are investing in the production of low-loss, high-frequency materials and the optimization of PCB designs for 5G applications:

- Shenzhen Fastprint Circuit Tech Co., Ltd.: Fastprint is a leading provider of high-frequency PCBs in China, offering solutions for 5G telecommunications equipment, automotive radar systems, and aerospace applications.

- Shennan Circuits Co., Ltd. (SCC): SCC has developed advanced materials and processes for the production of high-frequency PCBs, including low-loss substrates and optimized via structures for improved signal integrity.

Environmentally Friendly PCB Production

As environmental regulations become more stringent, Chinese PCB manufacturers are adopting eco-friendly production processes and materials. This includes the use of halogen-free materials, lead-free soldering, and the implementation of green manufacturing practices:

- Shenzhen Kinwong Electronic Co., Ltd.: Kinwong has implemented a range of environmentally friendly practices, including the use of halogen-free materials, lead-free soldering, and the recycling of waste materials.

- Guangdong Goworld Co., Ltd.: Goworld is a leading provider of eco-friendly PCBs in China, offering halogen-free and lead-free solutions for a wide range of applications.

Automation and Smart Manufacturing

Chinese PCB manufacturers are increasingly adopting automation and smart manufacturing technologies to improve efficiency, reduce costs, and enhance product quality. This includes the use of robotics, machine vision systems, and data analytics:

- Victory Giant Technology (Huizhou) Co., Ltd.: Victory Giant has invested heavily in automation and smart manufacturing technologies, implementing robotics and machine vision systems in its production lines.

- Guangdong Chaohua Technology Co., Ltd.: Chaohua has developed a smart manufacturing system that integrates data analytics, real-time monitoring, and predictive maintenance to optimize production processes and improve product quality.

FAQ

- What are the main advantages of China’s PCB industry?

- Large-scale production capacity

- Wide range of technologies and capabilities

- Competitive pricing

- Rapid product development and time-to-market

- How has the COVID-19 pandemic affected China’s PCB industry?

- Temporary disruptions in production and supply chains

- Increased demand for PCBs used in medical equipment and remote work/learning devices

- Accelerated adoption of automation and digital technologies

- What are the key challenges facing China’s PCB industry?

- Rising labor and material costs

- Increasing competition from other Asian countries (e.g., Vietnam, India)

- Trade tensions and geopolitical uncertainties

- How are Chinese PCB manufacturers addressing environmental concerns?

- Adopting eco-friendly materials and production processes

- Implementing green manufacturing practices and waste reduction initiatives

- Investing in renewable energy and energy-efficient technologies

- What is the future outlook for China’s PCB industry?

- Continued growth driven by 5G, IoT, and automotive electronics

- Increasing focus on advanced technologies (e.g., HDI, embedded PCBs)

- Further adoption of automation and smart manufacturing

- Potential consolidation and restructuring of the industry

Conclusion

China’s PCB industry has undergone remarkable growth and transformation over the past few decades, establishing the country as a global leader in PCB production. The industry encompasses a wide range of technologies and capabilities, from basic single-sided and double-sided PCBs to advanced HDI, flexible, and embedded PCBs. Key players in the industry, such as Zhen Ding Technology, Shennan Circuits, and Unimicron, have played a significant role in driving technological innovation and expanding production capacity.

As the global demand for electronic products continues to grow, China’s PCB industry is well-positioned to capitalize on emerging trends and opportunities. The rollout of 5G networks, the increasing adoption of IoT devices, and the growth of the automotive electronics market are expected to drive the development of advanced PCB technologies, such as high-frequency materials, embedded components, and flexible circuits.

However, the industry also faces several challenges, including rising labor and material costs, increasing competition from other Asian countries, and environmental concerns. To address these challenges, Chinese PCB manufacturers are adopting eco-friendly production processes, investing in automation and smart manufacturing technologies, and exploring new markets and applications.

Looking ahead, China’s PCB industry is expected to maintain its dominant position in the global market, driven by continued innovation, large-scale production capacity, and a supportive policy environment. As the industry evolves, it will be crucial for Chinese PCB manufacturers to stay at the forefront of technological advancement, adapt to changing market demands, and prioritize sustainability and environmental responsibility.

Leave a Reply