Introduction to Selective Soldering

Selective soldering is a process used in the manufacturing of printed circuit boards (PCBs) where specific components are soldered onto the board without affecting the surrounding components. This technique is particularly useful when dealing with through-hole components that cannot withstand the high temperatures of a reflow oven or when certain components need to be soldered separately due to their sensitivity or special requirements.

Advantages of Selective Soldering

Selective soldering offers several advantages over traditional wave soldering and reflow soldering methods:

-

Precision: Selective soldering allows for precise control over the soldering process, ensuring that only the desired components are soldered while leaving the rest of the board untouched.

-

Flexibility: This technique enables the soldering of a wide range of components, including through-hole components, surface mount devices (SMDs), and even odd-shaped or heat-sensitive components.

-

Reduced Thermal Stress: By targeting only specific areas of the PCB, selective soldering minimizes the thermal stress on the board and its components, reducing the risk of damage.

-

Cost-effective: Selective soldering can be more cost-effective than other methods, especially for low-volume production runs or boards with a mix of through-hole and surface mount components.

Selective Soldering Process

The selective soldering process involves several key steps:

1. PCB Preparation

Before selective soldering can begin, the PCB must be properly prepared:

- The board is cleaned to remove any contaminants or debris that could interfere with the soldering process.

- Solder paste is applied to the desired areas using a stencil or dispensing system.

- Components are placed on the board, either manually or using automated pick-and-place machines.

2. Flux Application

Flux is applied to the areas to be soldered to help remove oxides, improve wetting, and promote the formation of a strong solder joint. There are several methods for applying flux:

- Spray fluxing: A fine mist of flux is sprayed onto the targeted areas of the PCB.

- Brush fluxing: Flux is applied using a brush, allowing for more precise control over the application process.

- Dip fluxing: The board is dipped into a flux bath, coating the entire surface.

3. Preheating

The PCB is preheated to activate the flux and prepare the board and components for soldering. Preheating helps to:

- Evaporate any remaining solvents in the flux.

- Reduce thermal shock to the components during soldering.

- Improve the wetting of the solder.

4. Soldering

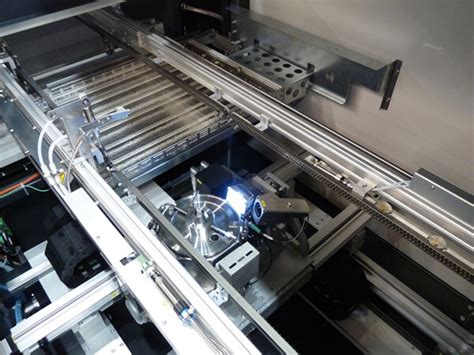

The actual soldering process is performed using a selective soldering machine, which typically consists of a solder pot, a nozzle, and a positioning system. There are two main types of selective soldering machines:

-

Point-to-point soldering: A single nozzle is used to solder each joint individually, providing the highest level of precision and control.

-

Multi-nozzle soldering: Multiple nozzles are used to solder several joints simultaneously, increasing throughput but reducing flexibility.

During the soldering process, the nozzle applies molten solder to the targeted areas of the PCB, creating a strong bond between the component leads and the board.

5. Cooling and Cleaning

After soldering, the board is allowed to cool naturally or is actively cooled using forced air. Once cooled, the board is cleaned to remove any residual flux or other contaminants.

Selective Soldering Equipment

Several types of equipment are used in the selective soldering process:

| Equipment | Description |

|---|---|

| Selective Soldering Machine | The main piece of equipment that performs the actual soldering process. It consists of a solder pot, nozzle(s), and a positioning system. |

| Fluxing System | Used to apply flux to the targeted areas of the PCB. This can be a spray fluxer, brush fluxer, or dip fluxer. |

| Preheating System | Heats the PCB to activate the flux and prepare the board and components for soldering. This can be an infrared (IR) heater, convection heater, or hot air system. |

| Solder Pot | Holds the molten solder used in the soldering process. The solder pot is typically made of a material with good thermal conductivity, such as titanium or a ceramic-coated steel. |

| Nozzles | Apply the molten solder to the targeted areas of the PCB. Nozzles come in various sizes and shapes to accommodate different component lead sizes and configurations. |

| Positioning System | Moves the PCB and/or the soldering nozzle to the correct position for soldering. This can be a gantry system, a robotic arm, or a combination of both. |

Selective Soldering Parameters

To achieve optimal results, several key parameters must be controlled during the selective soldering process:

Solder Temperature

The temperature of the molten solder must be carefully controlled to ensure proper wetting and to prevent damage to the components or PCB. Typical solder temperatures range from 450°F to 550°F (230°C to 290°C), depending on the type of solder alloy used.

Preheat Temperature

The preheat temperature is critical for activating the flux and preparing the board and components for soldering. Preheat temperatures typically range from 150°F to 300°F (65°C to 150°C), depending on the type of flux and the thermal mass of the components.

Dwell Time

Dwell time refers to the amount of time the solder nozzle remains in contact with the joint during soldering. Longer dwell times allow for better heat transfer and the formation of a stronger solder joint, but they also increase the risk of thermal damage to the components. Typical dwell times range from 1 to 5 seconds.

Solder Nozzle Size and Shape

The size and shape of the solder nozzle must be carefully selected to match the size and configuration of the component leads being soldered. Using the wrong nozzle size or shape can result in poor solder joint formation or damage to the components.

Flux Type and Application

The type of flux used and the method of application can have a significant impact on the quality of the solder joint. Different fluxes have different activation temperatures, cleaning requirements, and residue characteristics, so it’s essential to choose the right flux for the specific application.

Quality Control and Inspection

To ensure the highest quality solder joints, several inspection and quality control methods are used:

-

Visual inspection: Solder joints are visually inspected for proper wetting, fillets, and the absence of defects such as bridging, icicles, or insufficient solder.

-

Automated optical inspection (AOI): AOI systems use cameras and image processing algorithms to automatically inspect solder joints for defects.

-

X-ray inspection: X-ray systems are used to inspect solder joints that are hidden from view, such as those under BGA components.

-

Electrical testing: Functional and in-circuit testing are used to verify the electrical integrity of the soldered connections.

FAQ

1. What types of components can be soldered using selective soldering?

Selective soldering can be used for a wide range of components, including through-hole components, surface mount devices (SMDs), and odd-shaped or heat-sensitive components. However, it is most commonly used for through-hole components that cannot withstand the high temperatures of a reflow oven.

2. How does selective soldering differ from wave soldering?

Selective soldering differs from wave soldering in that it targets specific areas of the PCB for soldering, rather than exposing the entire board to a wave of molten solder. This allows for greater precision and control, and reduces the risk of thermal damage to sensitive components.

3. What are the main advantages of selective soldering?

The main advantages of selective soldering include precision, flexibility, reduced thermal stress, and cost-effectiveness. Selective soldering allows for precise control over the soldering process, can accommodate a wide range of components, minimizes thermal stress on the board and components, and can be more cost-effective than other methods for low-volume production runs or boards with mixed components.

4. What is the purpose of applying flux in selective soldering?

Flux is applied in selective soldering to remove oxides, improve wetting, and promote the formation of a strong solder joint. Flux helps to ensure that the molten solder adheres properly to the component leads and PCB pads, resulting in a reliable and robust connection.

5. How can the quality of selective soldering joints be inspected?

The quality of selective soldering joints can be inspected through various methods, including visual inspection, automated optical inspection (AOI), X-ray inspection, and electrical testing. These methods help to identify defects such as poor wetting, bridging, insufficient solder, or other issues that could impact the reliability and functionality of the soldered connections.

Leave a Reply