Introduction to PCB Fundamentals

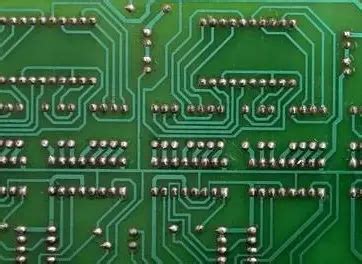

Printed Circuit Boards (PCBs) are the backbone of modern electronics. They are used in almost every electronic device, from smartphones and computers to medical equipment and aerospace systems. Understanding the fundamentals of PCBs is crucial for anyone involved in the design, manufacture, or use of electronic devices.

In this comprehensive guide, we will cover the basics of PCB fundamentals, including what PCBs are, how they are made, and the various types of PCBs available. We will also discuss the key components of PCBs, such as copper layers, solder mask, and silkscreen, and how they work together to create a functional circuit board.

What is a PCB?

A PCB is a thin board made of insulating material, such as fiberglass or plastic, with conductive copper traces printed on one or both sides. These copper traces are used to connect electronic components, such as resistors, capacitors, and integrated circuits (ICs), to form a complete circuit.

PCBs are designed using specialized software that allows engineers to lay out the circuit and generate the necessary files for manufacturing. Once the design is finalized, the PCB is manufactured using a multi-step process that involves etching, drilling, plating, and solder mask application.

Types of PCBs

There are several types of PCBs, each with its own unique characteristics and applications. The most common types of PCBs include:

- Single-sided PCBs: These PCBs have copper traces on only one side of the board and are typically used for simple, low-cost applications.

- Double-sided PCBs: These PCBs have copper traces on both sides of the board and are used for more complex circuits that require higher density and better signal integrity.

- Multi-layer PCBs: These PCBs have multiple layers of copper traces separated by insulating material. They are used for high-density, high-speed applications that require excellent signal integrity and EMI protection.

- Flexible PCBs: These PCBs are made of flexible material, such as polyimide, and can be bent or folded to fit into tight spaces or conformable applications.

- Rigid-Flex PCBs: These PCBs combine the benefits of both rigid and flexible PCBs, allowing for complex 3D designs and improved reliability.

Key Components of PCBs

PCBs are made up of several key components that work together to create a functional circuit board. These components include:

Copper Layers

The copper layers are the conductive traces that carry electrical signals between components on the PCB. The number of copper layers depends on the complexity of the circuit and the desired signal integrity. Single-sided PCBs have one copper layer, while multi-layer PCBs can have up to 50 or more layers.

Solder Mask

The solder mask is a protective coating applied to the copper layers to prevent short circuits and improve the PCB’s durability. It also provides insulation between adjacent traces and helps to prevent solder bridging during assembly.

Silkscreen

The silkscreen is a layer of text and symbols printed on top of the solder mask to provide information about the PCB, such as component designators, polarity markers, and test points. It helps to ensure proper assembly and troubleshooting of the PCB.

Vias

Vias are small holes drilled through the PCB to connect different layers of copper. They allow signals to pass between layers and are essential for multi-layer PCBs. There are several types of vias, including through-hole vias, blind vias, and buried vias.

Pads

Pads are the exposed areas of copper on the PCB where components are soldered. They come in various shapes and sizes depending on the component and the soldering method used.

PCB Manufacturing Process

The PCB manufacturing process involves several steps, each of which is critical to ensuring the quality and reliability of the final product. The basic steps in PCB manufacturing include:

PCB Design

The first step in PCB manufacturing is the design phase. This involves creating a schematic diagram of the circuit and laying out the components and traces on the PCB using specialized software. The design must take into account factors such as signal integrity, EMI, and thermal management.

Etching

Once the design is finalized, the next step is to create the copper traces on the PCB. This is done using a process called etching, which involves applying a photoresist layer to the copper and exposing it to light through a photomask. The exposed areas are then etched away using a chemical solution, leaving only the desired copper traces.

Drilling

After etching, the next step is to drill holes in the PCB for through-hole components and vias. This is done using a CNC drilling machine that precisely positions and drills the holes according to the design specifications.

Plating

The drilled holes are then plated with copper to create a conductive path between layers. This is done using a process called electroplating, which involves immersing the PCB in a copper sulfate solution and applying an electric current to deposit a thin layer of copper on the walls of the holes.

Solder Mask Application

The next step is to apply the solder mask to the PCB. This is done using a screen printing process that deposits a thin layer of solder mask ink over the copper traces, leaving only the pads and other exposed areas uncovered.

Silkscreen Printing

The final step in PCB manufacturing is to print the silkscreen layer on top of the solder mask. This is done using a similar screen printing process as the solder mask application, but with a different type of ink that is resistant to abrasion and chemicals.

PCB Assembly

Once the PCB is manufactured, the next step is to assemble the components onto the board. This is done using a process called soldering, which involves applying heat and solder to the pads and component leads to create a strong and reliable electrical connection.

There are several methods of PCB assembly, including:

Through-Hole Assembly

Through-hole assembly involves inserting the component leads through the holes in the PCB and soldering them to the pads on the opposite side. This method is typically used for larger components or those that require higher mechanical strength.

Surface-Mount Assembly

Surface-mount assembly involves placing the components directly on the pads on the surface of the PCB and soldering them in place. This method is typically used for smaller components and allows for higher density and faster assembly times.

Mixed Assembly

Mixed assembly involves using both through-hole and surface-mount components on the same PCB. This method is often used for complex designs that require a combination of different component types and sizes.

PCB Testing and Inspection

Once the PCB is assembled, it must be tested and inspected to ensure that it meets the required specifications and functions correctly. There are several methods of PCB testing and inspection, including:

Visual Inspection

Visual inspection involves visually examining the PCB for defects such as poor solder joints, missing components, or damaged traces. This can be done using a microscope or other magnification tool.

Automated Optical Inspection (AOI)

AOI involves using a camera and image processing software to automatically detect and analyze defects on the PCB. This method is faster and more reliable than visual inspection and can detect defects that are too small to see with the naked eye.

In-Circuit Testing (ICT)

ICT involves using a specialized test fixture to make electrical contact with the pads on the PCB and test the functionality of each component and connection. This method can detect problems such as open or short circuits, incorrect component values, or missing components.

Functional Testing

Functional testing involves powering up the PCB and testing its overall functionality and performance. This can include tests such as signal integrity, power consumption, and EMI emissions.

PCB Design Considerations

When designing a PCB, there are several key considerations that must be taken into account to ensure optimal performance and reliability. These include:

Signal Integrity

Signal integrity refers to the quality and consistency of the electrical signals that travel through the PCB. Factors that can affect signal integrity include impedance matching, crosstalk, and reflections. Good PCB design practices, such as proper trace routing and termination, can help to minimize these issues and ensure reliable signal transmission.

Thermal Management

Thermal management refers to the ability of the PCB to dissipate heat generated by the components. Poor thermal management can lead to component failure and reduced reliability. Good PCB design practices, such as proper component placement and the use of thermal vias, can help to improve thermal performance and ensure long-term reliability.

EMI/EMC

Electromagnetic interference (EMI) and electromagnetic compatibility (EMC) refer to the ability of the PCB to operate without interfering with or being affected by other electronic devices. Good PCB design practices, such as proper grounding and shielding, can help to minimize EMI and ensure compliance with EMC regulations.

Manufacturing Constraints

Manufacturing constraints refer to the limitations and requirements of the PCB manufacturing process. These can include factors such as minimum trace width and spacing, hole size and placement, and material selection. Good PCB design practices must take these constraints into account to ensure that the PCB can be manufactured reliably and cost-effectively.

Troubleshooting and Repair

Despite the best efforts of designers and manufacturers, PCBs can sometimes fail or malfunction in the field. When this happens, troubleshooting and repair techniques can be used to identify and fix the problem. Some common troubleshooting and repair techniques include:

Visual Inspection

As with PCB testing, visual inspection is often the first step in troubleshooting a malfunctioning PCB. This can involve looking for obvious signs of damage, such as burnt components or broken traces, as well as more subtle issues such as poor solder joints or incorrect component placement.

Multimeter Testing

A multimeter is a versatile tool that can be used to measure voltage, current, and resistance on a PCB. This can help to identify issues such as open or short circuits, incorrect component values, or faulty connections.

Oscilloscope Testing

An oscilloscope is a more advanced tool that can be used to visualize and analyze electrical signals on a PCB. This can help to identify issues such as signal integrity problems, noise, or timing errors.

Component Replacement

If a component on the PCB is found to be faulty or damaged, it may need to be replaced. This involves carefully desoldering the old component and soldering in a new one, taking care not to damage the surrounding components or traces.

Frequently Asked Questions (FAQ)

What is the difference between a PCB and a breadboard?

A breadboard is a temporary prototyping tool that allows you to quickly connect components and test circuits without soldering. A PCB, on the other hand, is a permanent, manufactured board that is designed to be used in a final product.

What is the difference between through-hole and surface-mount components?

Through-hole components have long leads that are inserted through holes in the PCB and soldered to pads on the opposite side. Surface-mount components are smaller and have flat pads that are soldered directly to the surface of the PCB.

What is the purpose of the solder mask on a PCB?

The solder mask is a protective coating that is applied to the copper traces on a PCB. It helps to prevent short circuits and improves the durability and reliability of the board.

How many layers can a PCB have?

PCBs can have anywhere from one to dozens of layers, depending on the complexity of the design and the required functionality. Most consumer electronics use PCBs with 4-8 layers, while high-end applications such as aerospace or medical devices may use PCBs with 20 or more layers.

What is the typical turnaround time for PCB manufacturing?

The turnaround time for PCB manufacturing can vary depending on the complexity of the design, the manufacturing process, and the supplier. Typical turnaround times range from a few days to several weeks, with rush options available for an additional cost.

Conclusion

PCBs are a critical component of modern electronics, enabling the complex functionality and high performance that we have come to expect from our devices. Understanding the basics of PCB fundamentals, including the manufacturing process, key components, and design considerations, is essential for anyone involved in the development or use of electronic products.

By following good PCB design practices and working with experienced manufacturers and suppliers, it is possible to create reliable, high-quality PCBs that meet the specific needs of your application. Whether you are a hobbyist working on a personal project or an engineer developing a commercial product, a solid understanding of PCB fundamentals will help you to achieve your goals and bring your ideas to life.

| PCB Type | Layers | Typical Applications |

|---|---|---|

| Single-sided | 1 | Simple, low-cost devices |

| Double-sided | 2 | More complex devices with higher density |

| Multi-layer | 4-8 | Most consumer electronics |

| Multi-layer | 20+ | High-end applications (aerospace, medical) |

| Flexible | 1-2 | Wearables, bendable devices |

| Rigid-Flex | 2+ | Complex 3D designs, high reliability |

Leave a Reply