Introduction to Turnkey PCB Assembly

Turnkey PCB (Printed Circuit Board) assembly is a comprehensive solution for electronic product manufacturing. It encompasses the entire process from PCB design to the final assembled product, making it an efficient and cost-effective approach for businesses of all sizes. In this article, we will explore the various aspects of turnkey PCB assembly, its benefits, and the key considerations when choosing a turnkey PCB assembly provider.

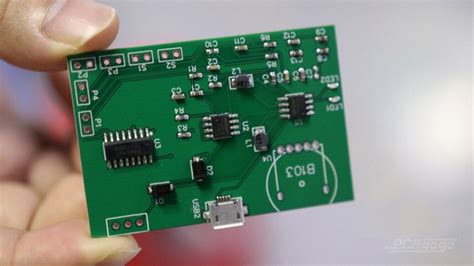

What is Turnkey PCB Assembly?

Turnkey PCB assembly is a complete solution that covers every stage of the PCB manufacturing process, from design to the finished product. It includes PCB design, fabrication, component sourcing, assembly, testing, and packaging. The term “turnkey” implies that the client receives a fully functional and ready-to-use product without having to manage the individual stages of the manufacturing process.

The Turnkey PCB Assembly Process

-

PCB Design: The first step in turnkey PCB assembly is the design of the printed circuit board. This involves creating a schematic diagram and a PCB layout using specialized software tools. The design must adhere to industry standards and consider factors such as component placement, signal integrity, and manufacturability.

-

PCB Fabrication: Once the design is finalized, the PCB is fabricated using a series of processes, including:

- Copper clad laminate preparation

- Drill hole creation

- Copper pattern printing and etching

- Solder mask application

-

Silkscreen printing

-

Component Sourcing: The turnkey PCB assembly provider is responsible for sourcing all the necessary components for the PCB. This includes resistors, capacitors, integrated circuits, connectors, and other electronic components. The provider ensures that the components are of high quality and are available in the required quantities.

-

PCB Assembly: The PCB assembly process involves placing the components onto the fabricated PCB and soldering them in place. There are two primary methods of PCB assembly:

- Surface Mount Technology (SMT): Components are placed on the surface of the PCB and soldered using a reflow oven.

-

Through-Hole Technology (THT): Components are inserted through holes in the PCB and soldered on the opposite side.

-

Testing and Quality Control: After the PCB is assembled, it undergoes rigorous testing to ensure its functionality and reliability. This may include:

- Visual inspection

- Automated Optical Inspection (AOI)

- In-Circuit Testing (ICT)

-

Functional testing

-

Packaging and Shipping: Once the PCBs have passed the testing phase, they are packaged according to the client’s requirements and shipped to their destination.

Benefits of Turnkey PCB Assembly

Turnkey PCB assembly offers several advantages for businesses looking to streamline their electronic product manufacturing process:

-

Time Savings: By outsourcing the entire PCB assembly process to a single provider, businesses can save significant time and focus on their core competencies. The turnkey approach eliminates the need to manage multiple vendors and coordinate the various stages of the manufacturing process.

-

Cost Efficiency: Turnkey PCB assembly providers often have established relationships with component suppliers and can negotiate better prices due to their high-volume purchases. This cost savings is passed on to the client, making turnkey assembly a more cost-effective solution compared to managing the process in-house.

-

Expertise and Quality: Turnkey PCB assembly providers have the necessary expertise and experience to ensure high-quality results. They invest in state-of-the-art equipment, employ skilled technicians, and follow strict quality control procedures to deliver reliable and consistent products.

-

Scalability: Turnkey PCB assembly services can accommodate various production volumes, from prototype runs to large-scale production. This scalability allows businesses to adapt to changing market demands and easily ramp up production when needed.

-

Reduced Inventory Management: With turnkey PCB assembly, the provider takes responsibility for managing the inventory of components and PCBs. This reduces the burden on the client to maintain and track inventory levels, freeing up resources and minimizing the risk of component obsolescence.

Choosing a Turnkey PCB Assembly Provider

When selecting a turnkey PCB assembly provider, consider the following factors:

-

Technical Capabilities: Ensure that the provider has the necessary equipment, expertise, and experience to handle your specific PCB assembly requirements. Inquire about their manufacturing capabilities, such as SMT and THT assembly, and their ability to work with various PCB materials and components.

-

Quality Standards: Look for a provider that adheres to industry quality standards, such as ISO 9001 and IPC standards. Ask about their quality control processes, testing procedures, and the certifications they hold.

-

Lead Times: Discuss the provider’s lead times for various production volumes and their ability to meet your delivery schedules. Consider their responsiveness and communication throughout the manufacturing process.

-

Cost and Pricing: Request quotes from multiple providers and compare their pricing structures. However, keep in mind that the lowest price may not always provide the best value. Consider the provider’s overall capabilities, quality, and reputation when making your decision.

-

Customer Support: Evaluate the level of customer support offered by the provider. Look for a provider that is responsive, communicative, and willing to address your concerns and requirements throughout the project.

Frequently Asked Questions (FAQ)

-

What is the minimum order quantity for turnkey PCB assembly?

The minimum order quantity varies among providers, but many offer low-volume production runs and even prototype assembly services. Some providers may have a minimum order quantity of 1-10 pieces, while others may require higher volumes. -

How long does the turnkey PCB assembly process take?

The lead time for turnkey PCB assembly depends on factors such as the complexity of the PCB design, the availability of components, and the production volume. Prototype runs can typically be completed within 1-2 weeks, while larger production runs may take several weeks. It’s essential to discuss lead times with your chosen provider and plan accordingly. -

Can I provide my own PCB design for turnkey assembly?

Yes, most turnkey PCB assembly providers accept client-provided PCB designs. However, it’s crucial to ensure that your design meets the provider’s manufacturing capabilities and guidelines. Many providers offer design review services to identify and address any potential issues before proceeding with fabrication and assembly. -

What file formats are required for PCB design submission?

The most common file formats for PCB design submission include Gerber files (RS-274X), drill files (Excellon), and pick-and-place files (CSV or XY coordinates). Some providers may also accept CAD files from popular PCB design software packages, such as Altium Designer or KiCad. -

How can I ensure the quality of the assembled PCBs?

To ensure the quality of the assembled PCBs, choose a provider that follows industry quality standards and has a robust quality control process in place. Discuss their testing procedures, such as AOI, ICT, and functional testing, and inquire about their quality metrics, such as defect rates and yield. Additionally, consider requesting a sample or prototype run to evaluate the quality of their work before proceeding with larger production volumes.

| Factor | Consideration |

|---|---|

| Technical Capabilities | Equipment, expertise, SMT/THT assembly, PCB materials and components |

| Quality Standards | ISO 9001, IPC standards, quality control processes, testing procedures, certifications |

| Lead Times | Production volumes, delivery schedules, responsiveness, communication |

| Cost and Pricing | Quotes, pricing structures, overall capabilities, quality, reputation |

| Customer Support | Responsiveness, communication, willingness to address concerns and requirements |

Table 1: Key Factors to Consider When Choosing a Turnkey PCB Assembly Provider

Conclusion

Turnkey PCB assembly offers a comprehensive and efficient solution for electronic product manufacturing. By outsourcing the entire PCB assembly process to a single provider, businesses can save time, reduce costs, and ensure high-quality results. When choosing a turnkey PCB assembly provider, consider their technical capabilities, quality standards, lead times, pricing, and customer support. By carefully evaluating these factors and selecting a reputable provider, businesses can streamline their PCB assembly process and bring their electronic products to market faster and more cost-effectively.

Leave a Reply