Properties of Gold, Silver, and Copper

Before delving into the specific advantages of gold in PCB fabrication, it is helpful to understand the key properties of gold, silver, and copper that are relevant to their use in electronic circuits.

| Property | Gold | Silver | Copper |

|---|---|---|---|

| Electrical Conductivity (S/m) | 4.10 x 10^7 | 6.30 x 10^7 | 5.96 x 10^7 |

| Thermal Conductivity (W/mK) | 318 | 429 | 401 |

| Corrosion Resistance | Excellent | Good | Poor |

| Cost | High | Moderate | Low |

As seen in the table above, silver has the highest electrical conductivity among the three metals, followed closely by copper and then gold. However, gold has the lowest thermal conductivity and the highest corrosion resistance. Additionally, gold is significantly more expensive than silver and copper.

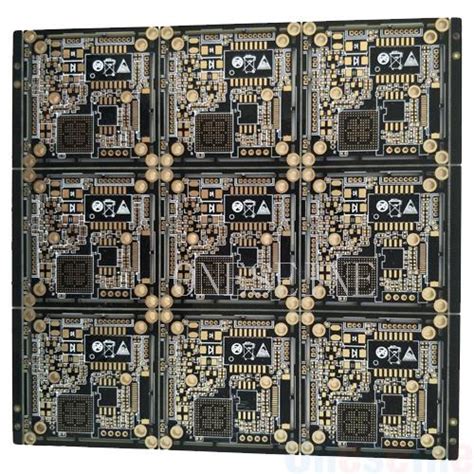

Advantages of Gold in PCB Fabrication

Despite its lower electrical conductivity and higher cost compared to silver and copper, gold offers several unique advantages that make it the preferred choice for many PCB applications.

Superior Corrosion Resistance

One of the most significant advantages of gold in PCB fabrication is its excellent corrosion resistance. Unlike copper and silver, which can tarnish and corrode when exposed to air, moisture, and other environmental factors, gold is highly resistant to oxidation and corrosion. This property makes gold an ideal choice for PCBs that will be used in harsh environments or exposed to corrosive substances.

In addition to its intrinsic corrosion resistance, gold can also be used as a protective coating for copper traces and pads. By applying a thin layer of gold over the copper, the PCB can benefit from the high conductivity of copper while being protected from corrosion by the gold layer. This technique, known as gold plating, is commonly used in high-reliability PCBs for aerospace, military, and medical applications.

Improved Signal Integrity

Another advantage of gold in PCB fabrication is its ability to improve signal integrity, particularly at high frequencies. Due to its lower electrical resistance and higher surface smoothness compared to copper and silver, gold can reduce signal attenuation and distortion, resulting in cleaner and more stable signals.

This property is particularly important in high-speed digital circuits, where signal integrity is critical for reliable data transmission. By using gold for the conductive traces and pads, designers can minimize signal losses and ensure that the digital signals remain clear and error-free, even at high frequencies.

Enhanced Solderability

Gold also offers superior solderability compared to copper and silver. Due to its resistance to oxidation, gold surfaces can be easily wetted by solder, resulting in strong and reliable solder joints. This property is particularly important for surface-mount components, where the quality of the solder joint can have a significant impact on the reliability and performance of the circuit.

In contrast, copper and silver surfaces can oxidize quickly, forming a thin layer of oxide that can interfere with the soldering process. To overcome this issue, copper and silver surfaces often require additional preparation steps, such as fluxing or pre-tinning, which can add complexity and cost to the PCB Assembly process.

Increased Durability and Reliability

The combination of gold’s corrosion resistance, improved signal integrity, and enhanced solderability results in PCBs with increased durability and reliability. Gold-plated PCBs can withstand harsh environmental conditions, such as high temperatures, humidity, and vibration, without degrading or failing.

This increased durability and reliability is particularly important in mission-critical applications, such as aerospace, military, and medical devices, where PCB failure can have catastrophic consequences. By using gold in these applications, designers can ensure that the PCBs will continue to function reliably over extended periods, even in challenging environments.

Compatibility with Wire Bonding

Gold is also the preferred material for wire bonding, a process used to make electrical connections between semiconductor chips and PCBs. In wire bonding, thin gold wires are attached to the bond pads on the chip and the corresponding pads on the PCB using heat and pressure.

Gold is chosen for wire bonding due to its excellent malleability, which allows the wires to be easily deformed and bonded to the pads without breaking. Additionally, gold’s resistance to oxidation ensures that the bond remains strong and reliable over time. In contrast, copper and silver are not suitable for wire bonding due to their higher hardness and tendency to oxidize.

Applications of Gold PCBs

Given the unique advantages of gold in PCB fabrication, gold PCBs are used in a wide range of applications where high performance, reliability, and durability are critical. Some common applications of gold PCBs include:

- Aerospace and Military Electronics

- Medical Devices and Implantable Electronics

- High-Frequency and RF Circuits

- Automotive Electronics

- Industrial Control Systems

In each of these applications, the use of gold PCBs helps to ensure that the electronic systems remain reliable and functional, even in challenging environments and over extended periods.

FAQ

1. Is gold always the best choice for PCB fabrication?

While gold offers several advantages over copper and silver, it is not always the best choice for every PCB application. The decision to use gold depends on the specific requirements of the design, such as the operating environment, signal integrity needs, and cost constraints. In some cases, copper or silver may be sufficient or even preferred.

2. How much more expensive are gold PCBs compared to Copper PCBs?

The cost of gold PCBs can vary depending on the specific design and manufacturing process, but they are generally significantly more expensive than copper PCBs. The higher cost is due to the price of gold itself, as well as the additional processing steps required for gold plating. However, the increased cost is often justified by the improved performance, reliability, and durability of gold PCBs in demanding applications.

3. Can gold be used in combination with other materials in PCB fabrication?

Yes, gold can be used in combination with other materials in PCB fabrication. For example, a common technique is to use a copper base for the conductive traces and pads, and then apply a thin layer of gold plating on top of the copper. This approach combines the high conductivity of copper with the corrosion resistance and solderability of gold, while also reducing the overall cost compared to using gold throughout the PCB.

4. Are there any environmental concerns associated with the use of gold in PCB fabrication?

The use of gold in PCB fabrication does raise some environmental concerns, primarily related to the mining and processing of gold. Gold mining can have significant environmental impacts, including deforestation, soil erosion, and water pollution. Additionally, the chemical processes used to extract and refine gold can generate hazardous waste and emissions. However, the electronics industry is increasingly focusing on responsible sourcing and recycling of gold to minimize these environmental impacts.

5. What are the challenges associated with gold plating in PCB fabrication?

One of the main challenges associated with gold plating in PCB fabrication is ensuring a uniform and consistent plating thickness across the entire surface of the PCB. Uneven plating can lead to variations in electrical conductivity and solderability, which can impact the performance and reliability of the circuit. Additionally, the gold plating process must be carefully controlled to avoid defects such as nodules, pits, and cracks, which can compromise the integrity of the plated surface. Proper process control and quality assurance measures are essential to overcome these challenges and produce high-quality gold-plated PCBs.

Conclusion

In conclusion, gold offers several unique advantages over silver and copper in PCB fabrication, including superior corrosion resistance, improved signal integrity, enhanced solderability, increased durability and reliability, and compatibility with wire bonding. These properties make gold the preferred choice for many high-performance and high-reliability PCB applications, particularly in demanding environments such as aerospace, military, and medical electronics.

While gold PCBs are generally more expensive than their copper and silver counterparts, the increased cost is often justified by the improved performance and reliability they offer. As the electronics industry continues to push the boundaries of performance and miniaturization, the use of gold in PCB fabrication is likely to remain an important tool in the designer’s toolkit.

Leave a Reply