What is a PCB?

A Printed Circuit Board, or PCB, is a custom-designed board used to electrically connect electronic components using conductive tracks, pads, and other features etched from copper sheets laminated onto a non-conductive substrate. PCBs are the foundation of most electronic devices we use today, from smartphones and computers to medical equipment and aerospace technology.

Types of PCBs

There are several types of PCBs, each with its own unique characteristics and applications:

-

Single-Layer PCB: A single-layer PCB has only one layer of copper on one side of the substrate. These boards are simple, cost-effective, and suitable for low-complexity circuits.

-

Double-layer PCB: Double-layer PCBs have two layers of copper, one on each side of the substrate. They offer more design flexibility and higher component density compared to single-layer PCBs.

-

Multi-layer PCB: Multi-layer PCBs consist of three or more layers of copper, separated by insulating layers. These boards are used for complex circuits that require high component density and signal integrity.

-

Flexible PCB: Flexible PCBs are made using flexible substrate materials, allowing them to bend and conform to different shapes. They are commonly used in wearable electronics and applications where space is limited.

-

Rigid-Flex PCB: Rigid-Flex PCBs combine the benefits of both rigid and flexible PCBs. They consist of rigid sections connected by flexible sections, offering the best of both worlds in terms of durability and flexibility.

Advantages of PCBs

PCBs offer several advantages over other circuit construction methods:

-

Reliability: PCBs are designed and manufactured to withstand harsh environmental conditions and offer high reliability, making them suitable for critical applications.

-

Consistency: PCBs are produced using automated processes, ensuring consistent quality and reducing the risk of human error.

-

Compact design: PCBs allow for high component density, enabling the creation of compact and space-efficient electronic devices.

-

High-speed performance: Multi-layer PCBs can be designed to optimize signal integrity and minimize electromagnetic interference, making them ideal for high-speed applications.

-

Cost-effective: Although the initial design and setup costs for PCBs can be higher than other methods, they are cost-effective for mass production due to their automated manufacturing process.

Disadvantages of PCBs

Despite their numerous advantages, PCBs also have some limitations:

-

Design complexity: Designing a PCB requires specialized knowledge and software, which can be time-consuming and costly.

-

Modification difficulties: Once a PCB is manufactured, it is difficult to modify the circuit without redesigning and reproducing the board.

-

Higher initial costs: The design and setup costs for PCBs can be higher compared to other prototyping methods, particularly for low-volume production.

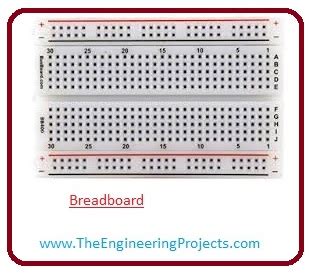

What is a Breadboard?

A breadboard is a reusable prototyping tool used to create temporary electrical circuits without the need for soldering. It consists of a plastic board with a grid of interconnected metal clips that allow the insertion of electronic components and jumper wires to create a circuit.

How do Breadboards Work?

Breadboards have a specific layout that enables the creation of electrical connections:

-

Terminal strips: Breadboards have two types of terminal strips – the power rails and the component strips. The power rails run horizontally along the top and bottom edges of the breadboard and are typically used for connecting power supply and ground. The component strips run vertically and are used for connecting electronic components.

-

Metal clips: Each terminal strip consists of metal clips that are connected internally. In the power rails, the clips are connected horizontally, while in the component strips, the clips are connected vertically in groups of five.

-

Component insertion: Electronic components, such as resistors, capacitors, and integrated circuits, can be inserted into the component strips by pushing their leads into the metal clips. Jumper wires are used to create connections between the components and the power rails.

Advantages of Breadboards

Breadboards offer several advantages for prototyping and circuit design:

-

Reusability: Breadboards are reusable, allowing you to create and modify circuits quickly without the need for soldering.

-

Flexibility: Breadboards offer great flexibility in circuit design, as components can be easily added, removed, or repositioned.

-

Cost-effective: Breadboards are relatively inexpensive compared to other prototyping methods, making them accessible to hobbyists and students.

-

Easy to use: Breadboards require no special skills or tools, making them easy to use for beginners and experienced users alike.

Disadvantages of Breadboards

While breadboards are convenient for prototyping, they also have some limitations:

-

Temporary nature: Breadboard circuits are temporary and are not suitable for permanent installations or commercial products.

-

Limited current capacity: Breadboards have a limited current capacity due to the small size of the metal clips, making them unsuitable for high-power applications.

-

Prone to loose connections: The metal clips in breadboards can become loose over time, leading to intermittent connections and circuit failures.

-

Limited high-frequency performance: Breadboards are not suitable for high-frequency circuits due to the inherent capacitance and inductance of the metal clips and jumper wires.

PCB vs Breadboard: Which One to Choose?

The choice between a PCB and a breadboard depends on the specific requirements of your project:

When to Use a PCB

-

Final product: If you are designing a circuit for a final product or a permanent installation, a PCB is the best choice due to its reliability, consistency, and compact design.

-

High-speed circuits: For high-speed applications or circuits sensitive to electromagnetic interference, a well-designed PCB can provide better signal integrity and noise reduction.

-

Mass production: If you plan to produce a large number of identical circuits, PCBs are more cost-effective due to their automated manufacturing process.

When to Use a Breadboard

-

Prototyping: Breadboards are ideal for prototyping and testing circuit designs, as they allow for quick and easy modifications without the need for soldering.

-

Educational purposes: Breadboards are often used in educational settings to teach electronic concepts and circuit design, as they provide a hands-on learning experience.

-

Low-complexity circuits: For simple circuits with a small number of components, a breadboard can be a quick and cost-effective solution.

Transitioning from Breadboard to PCB

Once you have successfully prototyped and tested your circuit on a breadboard, you may want to transition to a PCB for a more permanent and reliable solution. Here are some steps to follow:

-

Schematic design: Create a schematic diagram of your circuit using electronic design automation (EDA) software, such as KiCad or Eagle. This schematic will serve as a blueprint for your PCB Design.

-

Component selection: Choose components that are suitable for PCB mounting, considering factors such as package type, size, and pitch.

-

PCB layout: Design the PCB layout using the EDA software, following best practices for component placement, routing, and signal integrity.

-

Manufacturing: Once your PCB design is complete, send the design files to a PCB manufacturing service or fabricate the board yourself if you have the necessary equipment.

-

Assembly: Solder the components onto the PCB, either manually or using automated assembly techniques, depending on the complexity of your circuit and the number of boards required.

FAQs

-

Q: Can I use a breadboard for a permanent installation?

A: No, breadboards are not suitable for permanent installations due to their temporary nature and limited current capacity. -

Q: Are PCBs more expensive than breadboards?

A: The initial design and setup costs for PCBs can be higher than breadboards, but PCBs are more cost-effective for mass production due to their automated manufacturing process. -

Q: Can I reuse a PCB like a breadboard?

A: Unlike breadboards, PCBs are not designed for reuse. Once a PCB is manufactured and assembled, it is difficult to modify the circuit without redesigning and reproducing the board. -

Q: Do I need special skills to use a breadboard?

A: No, breadboards are easy to use and require no special skills or tools, making them accessible to beginners and experienced users alike. -

Q: Can I use a breadboard for high-frequency circuits?

A: Breadboards are not suitable for high-frequency circuits due to the inherent capacitance and inductance of the metal clips and jumper wires. For high-frequency applications, a well-designed PCB is recommended.

Conclusion

PCBs and breadboards are essential tools in the world of electronic circuit design, each with its own unique characteristics, advantages, and disadvantages. Breadboards are ideal for prototyping, testing, and educational purposes, while PCBs are best suited for final products, high-speed circuits, and mass production.

By understanding the differences between PCBs and breadboards, you can make an informed decision on which one to use for your specific project requirements. Whether you are a beginner learning the basics of electronics or an experienced engineer designing complex circuits, having a clear understanding of these tools will help you create successful and reliable electronic devices.

| Characteristic | PCB | Breadboard |

|---|---|---|

| Application | Final products, high-speed circuits, mass production | Prototyping, testing, educational purposes |

| Reusability | Not reusable | Reusable |

| Reliability | High reliability, consistent quality | Prone to loose connections and intermittent failures |

| Modification | Difficult to modify after manufacturing | Easy to modify and update |

| Cost | Higher initial costs, cost-effective for mass production | Low cost, accessible for hobbyists and students |

| Skills Required | Specialized knowledge and software for design | No special skills required |

| Current Capacity | Higher current capacity, suitable for high-power applications | Limited current capacity |

| High-Frequency Performance | Suitable for high-frequency circuits with proper design | Not suitable for high-frequency circuits |

Leave a Reply