Introduction to Single-Layer PCB

A single-layer PCB, also known as a single-sided PCB, is a printed circuit board that has conductive copper traces on only one side of the board. This type of PCB is the simplest and most cost-effective option for electronic circuits with low complexity and density. Single-layer PCBs are widely used in various applications, such as consumer electronics, hobby projects, and prototyping.

Advantages of Single-Layer PCBs

- Cost-effective: Single-layer PCBs are the most affordable option due to their simple design and manufacturing process.

- Easy to design: Designing a single-layer PCB is relatively straightforward, as there are fewer constraints compared to multi-layer boards.

- Quick turnaround: The manufacturing process for single-layer PCBs is faster than that of multi-layer boards, allowing for shorter lead times.

- Suitable for low-density circuits: Single-layer PCBs are ideal for projects with a low component count and simple interconnections.

Disadvantages of Single-Layer PCBs

- Limited routing options: With only one side available for copper traces, single-layer PCBs have limited routing options, which can lead to larger board sizes or difficulty in accommodating complex circuits.

- Reduced electrical performance: Single-layer PCBs may have lower electrical performance compared to multi-layer boards, as there is no ground plane to reduce electromagnetic interference (EMI) and improve signal integrity.

- Not suitable for high-density circuits: As circuit complexity and component count increase, single-layer PCBs may not be able to accommodate the required interconnections and routing.

Single-Layer PCB Manufacturing Process

The manufacturing process for single-layer PCBs involves several steps, including:

-

PCB Design: The circuit schematic is created using electronic design automation (EDA) software, and the PCB layout is designed according to the schematic and design rules.

-

Film Generation: The PCB layout is used to generate photographic films or digital files for the copper layer and Solder Mask.

-

Copper Lamination: A thin layer of copper foil is laminated onto the base material, typically FR-4 (a glass-reinforced epoxy laminate).

-

Photoresist Application: A photoresist layer is applied to the copper surface to protect the areas that will form the conductive traces.

-

Exposure and Development: The photoresist is exposed to UV light through the photographic film or digital mask, and then developed to remove the unexposed areas.

-

Etching: The exposed copper is removed using a chemical etching process, leaving only the desired conductive traces.

-

Solder Mask Application: A solder mask layer is applied to protect the copper traces and prevent solder bridges during the assembly process.

-

Silkscreen Printing: Text, logos, and component identifiers are printed on the PCB surface using silkscreen printing.

-

Surface Finish: A surface finish, such as HASL (Hot Air Solder Leveling) or ENIG (Electroless Nickel Immersion Gold), is applied to the exposed copper to improve solderability and prevent oxidation.

-

Drilling: Holes are drilled through the PCB for Through-hole components and mounting purposes.

-

Cutting and Routing: The PCB panel is cut and routed to the desired shape and size.

-

Quality Control: The finished PCBs undergo inspection and testing to ensure they meet the required specifications and quality standards.

Single-Layer PCB Design Considerations

When designing a single-layer PCB, there are several factors to consider to ensure optimal performance and manufacturability:

Component Placement

- Group related components together to minimize the length of interconnections and reduce signal interference.

- Place components in a logical flow, following the signal path from input to output.

- Consider the physical size and orientation of components to ensure they fit within the available board space.

Trace Routing

- Use an appropriate trace width based on the current carrying requirements and the PCB manufacturing capabilities.

- Maintain proper spacing between traces to avoid short circuits and minimize crosstalk.

- Avoid sharp corners and use 45-degree angles or curved traces to improve signal integrity and manufacturability.

- Use vias sparingly, as they can increase the manufacturing cost and complexity of single-layer PCBs.

Power and Ground Distribution

- Use wider traces for power and ground connections to minimize voltage drops and improve current carrying capacity.

- Place power and ground pins of components close to the corresponding power and ground traces to reduce loop area and minimize EMI.

- Consider using a ground plane on the opposite side of the board, if possible, to improve signal integrity and EMI performance.

Solder Mask and Silkscreen

- Ensure adequate solder mask clearance around pads and vias to prevent solder bridging.

- Use silkscreen labels to clearly identify components, pin numbers, and polarity indicators.

- Keep silkscreen text and graphics away from pads and traces to avoid interference with the soldering process.

Applications of Single-Layer PCBs

Single-layer PCBs are used in a wide range of applications, including:

- Consumer electronics: Simple devices such as toys, calculators, and remote controls often use single-layer PCBs.

- Hobby projects: Single-layer PCBs are popular among hobbyists and DIY enthusiasts for their low cost and ease of design.

- Prototyping: Single-layer PCBs are often used for initial prototypes and proof-of-concept designs before moving to more complex multi-layer boards.

- Educational purposes: Single-layer PCBs are used in educational settings to teach students about electronic circuits and PCB design principles.

Comparison of Single-Layer PCBs with Other PCB Types

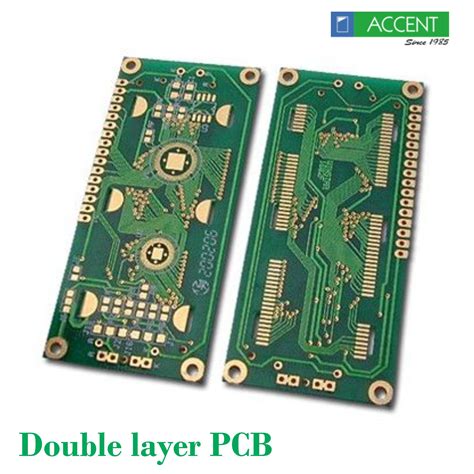

| PCB Type | Layers | Cost | Complexity | Applications |

|---|---|---|---|---|

| Single-Layer | 1 | Low | Low | Simple circuits, hobby projects, prototyping |

| Double-Layer | 2 | Medium | Medium | More complex circuits, improved signal integrity |

| Multi-Layer | 4+ | High | High | High-density circuits, advanced electronics |

| Flexible | 1-2 | High | Medium | Wearable electronics, space-constrained applications |

| Rigid-Flex | 1-20+ | Very High | Very High | Complex 3D circuits, aerospace, military |

Frequently Asked Questions (FAQ)

1. What is the mAXImum number of components that can be placed on a single-layer PCB?

The number of components that can be placed on a single-layer PCB depends on the size of the board, the size of the components, and the complexity of the interconnections. Generally, single-layer PCBs are suitable for circuits with low to medium component density, typically up to 100 components.

2. Can single-layer PCBs be used for high-frequency applications?

Single-layer PCBs are not ideal for high-frequency applications due to their limited ability to control impedance and reduce EMI. For high-frequency circuits, multi-layer PCBs with dedicated ground planes and Controlled Impedance traces are recommended.

3. What are the typical copper thickness options for single-layer PCBs?

The most common copper thickness options for single-layer PCBs are 1 oz (35 µm) and 2 oz (70 µm). Thicker copper layers can be used for high-current applications, but they may increase the cost and complexity of the manufacturing process.

4. Are there any limitations on the minimum trace width and spacing for single-layer PCBs?

The minimum trace width and spacing for single-layer PCBs depend on the PCB manufacturer’s capabilities and the chosen copper thickness. Typical minimum trace width and spacing for a 1 oz copper layer are 0.006 inches (0.15 mm) and 0.008 inches (0.2 mm), respectively. However, it is essential to consult with the PCB manufacturer to determine their specific capabilities and design rules.

5. Can single-layer PCBs be used for surface mount components?

Yes, single-layer PCBs can be used for surface mount components. However, the placement and routing of surface mount components on a single-layer board may be more challenging compared to through-hole components due to the limited routing options and the need for proper solder mask and pad design.

Conclusion

Single-layer PCBs are a cost-effective and straightforward solution for low-complexity electronic circuits. They offer advantages such as quick turnaround times and ease of design, making them suitable for a wide range of applications, including consumer electronics, hobby projects, and prototyping. However, single-layer PCBs have limitations in terms of routing options, electrical performance, and suitability for high-density circuits.

When designing a single-layer PCB, it is essential to consider factors such as component placement, trace routing, power and ground distribution, and proper use of solder mask and silkscreen. By understanding the manufacturing process, design considerations, and limitations of single-layer PCBs, designers can create efficient and reliable electronic circuits that meet their specific requirements.

Leave a Reply