Introduction to LED PCB

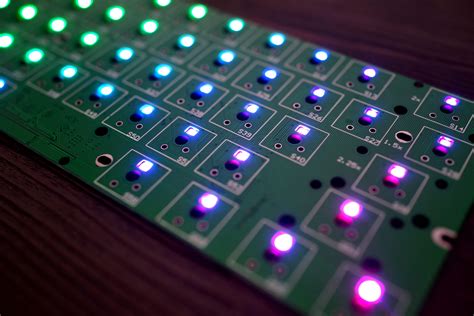

An LED PCB, or Light Emitting Diode Printed Circuit Board, is a specialized type of circuit board designed to efficiently power and control LED lights. LEDs have gained immense popularity in recent years due to their energy efficiency, long lifespan, and versatility in various applications. LED PCBs play a crucial role in ensuring optimal performance and reliability of LED lighting systems.

Components of an LED PCB

An LED PCB typically consists of the following components:

- Substrate: The base material of the PCB, usually made of FR-4 or aluminum.

- Copper Layers: Conductive copper traces that carry electrical signals and power to the LEDs.

- Solder mask: A protective layer that covers the copper traces, preventing short circuits and oxidation.

- Silkscreen: Text and symbols printed on the PCB for identification and assembly purposes.

- LEDs: The light-emitting diodes mounted on the PCB.

- Resistors: Components that limit the current flowing through the LEDs to prevent damage.

- Capacitors: Components that smooth out voltage fluctuations and reduce noise.

- Connectors: Pins or headers that allow the LED PCB to connect to power sources or other devices.

Types of LED PCBs

There are several types of LED PCBs, each designed for specific applications and requirements:

Single-Sided LED PCB

A single-sided LED PCB has copper traces and components on only one side of the substrate. These boards are generally less complex and more cost-effective than double-sided or multi-layer PCBs. Single-sided LED PCBs are suitable for simple LED lighting applications with lower power requirements.

Double-Sided LED PCB

Double-sided LED PCBs have copper traces and components on both sides of the substrate, allowing for higher component density and more complex circuit designs. These boards offer better heat dissipation and improved electrical performance compared to single-sided PCBs. Double-sided LED PCBs are commonly used in medium-power LED lighting applications.

Multi-Layer LED PCB

Multi-layer LED PCBs consist of three or more layers of copper traces separated by insulating material. These boards offer the highest level of complexity and performance, allowing for dense component placement and intricate circuit routing. Multi-layer LED PCBs are ideal for high-power LED lighting applications that require optimal thermal management and electrical efficiency.

Flexible LED PCB

Flexible LED PCBs are made of thin, flexible substrates such as polyimide or polyester. These boards can bend and conform to various shapes, making them suitable for applications where the LED lighting needs to be integrated into curved or irregular surfaces. Flexible LED PCBs are commonly used in wearable electronics, automotive lighting, and display backlighting.

Metal Core LED PCB (MCPCB)

Metal Core LED PCBs, also known as Aluminum PCBs, feature a metal substrate (usually aluminum) that provides excellent thermal conductivity. The metal core helps dissipate heat generated by the LEDs, ensuring better thermal management and longevity. MCPCBs are widely used in high-power LED lighting applications, such as street lights, floodlights, and grow lights.

Advantages of LED PCBs

LED PCBs offer several advantages over traditional lighting solutions:

-

Energy Efficiency: LEDs consume significantly less power compared to incandescent or fluorescent lights, resulting in substantial energy savings.

-

Long Lifespan: LEDs mounted on well-designed PCBs can last up to 50,000 hours or more, reducing maintenance costs and waste.

-

Compact Size: LED PCBs enable the creation of compact and lightweight lighting fixtures, allowing for greater design flexibility and space savings.

-

Rapid Switching: LEDs can be switched on and off instantly, making them suitable for applications that require fast response times, such as automotive brake lights or strobe lights.

-

Environmentally Friendly: LEDs do not contain hazardous materials like mercury, making them a more eco-friendly lighting option.

LED PCB Design Considerations

Designing an LED PCB requires careful consideration of several factors to ensure optimal performance, reliability, and longevity:

Thermal Management

Proper thermal management is crucial for LED PCBs, as excessive heat can reduce the lifespan and efficiency of LEDs. Some key thermal management strategies include:

- Using a metal core PCB (MCPCB) or a PCB with a thick copper layer to dissipate heat effectively.

- Incorporating thermal vias to transfer heat from the LED pads to the opposite side of the PCB.

- Designing adequate spacing between LEDs to prevent heat buildup.

- Using thermal interface materials (TIMs) to improve heat transfer between the LED and the PCB.

Current and Voltage Requirements

LEDs have specific current and voltage requirements that must be met to ensure proper operation and prevent damage. When designing an LED PCB, consider the following:

- Use current-limiting resistors or constant current drivers to regulate the current flowing through the LEDs.

- Ensure that the power supply provides the appropriate voltage and current for the LED array.

- Consider voltage drop across the PCB traces and components when calculating the required supply voltage.

LED Placement and Spacing

The placement and spacing of LEDs on the PCB can significantly impact the overall light output and visual appearance of the lighting fixture. Consider the following:

- Arrange LEDs in a pattern that provides the desired light distribution and intensity.

- Maintain consistent spacing between LEDs to ensure uniform light output.

- Consider the viewing angle of the LEDs and orient them accordingly.

PCB Material Selection

The choice of PCB material depends on the specific requirements of the LED lighting application. Factors to consider include:

- Thermal conductivity: For high-power applications, choose materials with good thermal conductivity, such as aluminum or copper-clad laminates.

- Dielectric strength: Ensure that the PCB material can withstand the required voltage without breakdown.

- Cost: Balance the performance requirements with the cost of the PCB material.

Color Consistency and Binning

LEDs can vary in color temperature and brightness due to manufacturing tolerances. To ensure color consistency across a large number of LEDs, consider the following:

- Use LEDs from the same bin or chromaticity group to minimize color variations.

- Implement color mixing techniques, such as using multiple LEDs of different colors or incorporating diffusers.

Manufacturing Process of LED PCBs

The manufacturing process of LED PCBs involves several key steps:

-

PCB Design: The LED PCB layout is designed using electronic design automation (EDA) software, taking into account the various design considerations mentioned earlier.

-

PCB Fabrication: The PCB is manufactured using a multi-step process that includes:

- Printing the circuit pattern onto the copper-clad laminate.

- Etching away the unwanted copper to create the desired traces.

- Applying a solder mask and silkscreen to protect the traces and add labels.

-

Drilling holes for through-hole components and vias.

-

Component Placement: LEDs and other components are placed onto the PCB using automated pick-and-place machines or manual assembly methods.

-

Soldering: The components are soldered onto the PCB using Reflow Soldering, wave soldering, or hand soldering techniques.

-

Testing and Inspection: The assembled LED PCB undergoes various tests to ensure proper functionality, including visual inspections, electrical tests, and burn-in tests.

-

Conformal Coating (Optional): A conformal coating may be applied to the LED PCB to protect it from environmental factors such as moisture, dust, and corrosion.

Applications of LED PCBs

LED PCBs find applications in a wide range of industries and products, including:

-

General Lighting: LED PCBs are used in various lighting fixtures, such as bulbs, tubes, panels, and downlights, for residential, commercial, and industrial settings.

-

Automotive Lighting: LED PCBs are extensively used in automotive lighting applications, including headlights, taillights, brake lights, and interior lighting.

-

Signage and Displays: LED PCBs are commonly used in digital signage, billboards, and information displays, offering high brightness, wide viewing angles, and low power consumption.

-

Backlighting: LED PCBs are used for backlighting LCD screens in televisions, monitors, laptops, and mobile devices, providing uniform and efficient illumination.

-

Horticulture Lighting: LED PCBs designed for horticulture applications provide the specific wavelengths of light required for plant growth, enabling energy-efficient indoor farming and greenhouse lighting.

-

Medical Devices: LED PCBs are used in various medical devices, such as endoscopes, surgical lights, and phototherapy equipment, offering high precision and reliability.

-

Wearable Electronics: Flexible LED PCBs are used in wearable devices, such as smart clothing, fitness trackers, and safety gear, providing lightweight and conformable lighting solutions.

Future Trends in LED PCB Technology

As LED technology continues to evolve, so do LED PCBs. Some of the future trends in LED PCB technology include:

-

Miniaturization: Advancements in LED packaging and PCB manufacturing technologies are enabling the development of smaller and more compact LED PCBs, allowing for even greater design flexibility.

-

High-Density Interconnect (HDI) PCBs: HDI PCBs, which feature fine pitch traces and micro vias, are becoming increasingly popular for LED applications, enabling higher component density and improved electrical performance.

-

Smart Lighting: LED PCBs are being integrated with sensors, wireless communication modules, and control systems to enable smart lighting solutions that can be remotely monitored and controlled.

-

Sustainable Materials: There is a growing trend towards using eco-friendly and recyclable materials in LED PCB manufacturing, such as halogen-free laminates and lead-free solders.

-

Improved Thermal Management: Advances in thermal management technologies, such as the use of graphene or other high-conductivity materials, are expected to further enhance the heat dissipation capabilities of LED PCBs.

Conclusion

LED PCBs have revolutionized the lighting industry, offering numerous benefits over traditional lighting solutions. By understanding the various types of LED PCBs, design considerations, and manufacturing processes, engineers and designers can create efficient, reliable, and long-lasting LED lighting products. As technology continues to advance, LED PCBs are expected to play an even more significant role in shaping the future of lighting.

Frequently Asked Questions (FAQ)

-

What is the difference between an LED PCB and a regular PCB?

An LED PCB is specifically designed to power and control LEDs, while a regular PCB is a general-purpose circuit board that can be used for various electronic applications. LED PCBs often incorporate specialized features, such as thermal management and current regulation, to ensure optimal LED performance. -

Can I use a regular PCB for my LED project?

While it is possible to use a regular PCB for an LED project, it is not recommended, especially for high-power applications. LED PCBs are designed with specific considerations, such as thermal management and current regulation, which are essential for ensuring the longevity and efficiency of LEDs. -

What is the expected lifespan of an LED PCB?

The lifespan of an LED PCB depends on various factors, including the quality of the components, the design of the PCB, and the operating environment. A well-designed LED PCB with high-quality components can last up to 50,000 hours or more when operated within its specified parameters. -

How do I choose the right LED PCB for my project?

When selecting an LED PCB for your project, consider factors such as the power requirements of your LEDs, the desired light output and distribution, the operating environment, and the budget. Consult with an experienced PCB manufacturer or LED lighting expert to help you make the right choice. -

Can I customize an LED PCB for my specific application?

Yes, LED PCBs can be customized to meet the specific requirements of your application. Many PCB manufacturers offer custom design and fabrication services, allowing you to create an LED PCB that is tailored to your needs in terms of size, shape, component placement, and features.

Leave a Reply