What is PCB Flux and Why Does It Need to Be Removed?

PCB flux is a chemical compound used in the soldering process when assembling printed circuit boards (PCBs). The main purpose of flux is to improve solderability by removing oxidation from metal surfaces and preventing re-oxidation during soldering. Flux also helps the molten solder flow more easily over the joint area.

However, after the soldering process is complete, any flux residue remaining on the PCB needs to be thoroughly removed. If left on the board, flux residue can cause various issues such as:

- Corrosion of metal surfaces and solder joints over time

- Degradation of electrical insulation

- Attracting moisture and contaminants

- Interfering with adhesion of conformal coatings

- Affecting visual inspection of solder joints

Therefore, proper cleaning and removal of flux residues is a critical step in PCB assembly to ensure reliability and performance of the final product. The specific flux removal method depends on the type of flux used.

Types of Soldering Flux

There are three main categories of fluxes used in PCB assembly:

| Flux Type | Composition | Residue | Cleaning |

|---|---|---|---|

| Rosin (R) | Rosin + activators | Minimal, non-corrosive | Optional |

| Water-soluble (WS) | Organic acids, glycols, isopropanol | Corrosive | Required |

| No-clean (NC) | Rosin/resin + organic acids | Minimal, non-corrosive | Not required |

Rosin Flux

Rosin fluxes are made from purified pine resin dissolved in isopropyl alcohol (IPA) or other solvents. They are available in various activity levels:

- R: Rosin – Mildest, minimal activators

- RMA: Rosin Mildly Activated – Mild activators

- RA: Rosin Activated – Strongest, highly activated

The more active the flux, the better its oxide removal ability but the more residue it leaves behind. Rosin flux residues are non-conductive and non-corrosive, so cleaning is optional depending on the specific application. However, the residues are sticky and can cause issues if left on the PCB.

Water-Soluble Flux

Water-soluble fluxes contain organic acids like lactic, citric or succinic acid as activators, combined with glycols and alcohols. They provide very good oxide removal but leave behind corrosive and conductive residues that must be cleaned from the PCB. The residues are easily removed with warm distilled water.

No-Clean Flux

No-clean fluxes are designed to leave minimal, benign residue after soldering that does not require cleaning in most applications. They typically consist of a resin or rosin base with weak organic acids as activators. While no-clean flux residues are considered safe to leave on the PCB, some manufacturers still prefer to remove them for enhanced reliability or to facilitate inspection and testing.

Flux Removal Methods

The three main methods for removing flux residues from PCBs are:

- Solvent cleaning

- Aqueous cleaning

- Semi-aqueous cleaning

The appropriate cleaning method depends on the type of flux used and the specific production requirements. Here is a comparison of the different cleaning methods:

| Method | Solvents | Applicable Flux Types | Advantages | Disadvantages |

|---|---|---|---|---|

| Solvent | IPA, ethanol, acetone | R, RMA, NC | Fast, simple, spot cleaning | Flammable, VOC emissions |

| Aqueous | Water + detergents | WS, R, RMA | Environmentally friendly, low-cost | Slower, requires drying |

| Semi-aqueous | Solvents + water rinse | WS, R, RMA, NC | Thorough cleaning, fast drying | Higher cost, chemical disposal |

Solvent Cleaning

Solvent cleaning uses organic solvents to dissolve and remove flux residues. The most common solvents are isopropyl alcohol (IPA), ethanol and acetone. Solvent cleaning can be performed manually by wiping the PCB with solvent-soaked wipes or using an aerosol spray. For more automated cleaning, vapor degreasing or ultrasonic cleaning equipment can be used.

Solvent cleaning is fast, simple and effective for removing rosin-based no-clean and RMA flux residues. It is often used for spot cleaning of specific areas on the PCB. However, solvents have some disadvantages:

- Flammable and volatile, pose safety risks

- Emit VOCs (volatile organic compounds), not environmentally friendly

- Can damage some plastics and components on the PCB

- Leave behind some residues as the solvent evaporates

Aqueous Cleaning

Aqueous cleaning uses water combined with detergents or saponifiers to remove flux residues. The water is usually heated and applied to the PCB via spray or immersion in a tank. Inline spray or batch immersion cleaning systems are commonly used. An additional rinsing step with deionized (DI) water is performed after washing to remove any remaining detergent.

Aqueous cleaning is very effective for removing polar, water-soluble flux residues. It can also remove rosin-based residues with the right detergent chemistry. Aqueous cleaning is environmentally friendly, low-cost, and leaves minimal residue. However, it has some limitations:

- Takes longer than solvent cleaning, especially with an additional rinsing step

- Requires thorough drying of the PCB to prevent moisture issues

- High water usage and need for wastewater treatment

- Some detergents can be alkaline and corrode aluminum or other metals

Semi-Aqueous Cleaning

Semi-aqueous cleaning is a two-stage process that combines solvent and aqueous cleaning. First, a solvent such as a terpene or glycol ether is used to dissolve and remove the bulk of the flux residue. Then, the PCB is rinsed with water to remove any remaining solvent and residue. The solvent is typically applied by spraying, and the water rinse is performed in a separate chamber.

Semi-aqueous cleaning provides thorough removal of all types of flux residues, including heavy, non-polar residues. It also minimizes the use of solvents compared to pure solvent cleaning and allows for faster drying than aqueous cleaning. The main drawbacks are higher equipment costs and the need to properly dispose of used solvents.

PCB Flux Removal Procedure

Regardless of the specific cleaning method used, proper PCB flux removal generally involves the following steps:

-

Pre-cleaning inspection: Visually inspect the PCB for any gross contamination, particulates or obvious defects that need to be addressed before cleaning.

-

Cleaning: Apply the chosen cleaning agent (solvent, aqueous detergent or semi-aqueous solvent) to the PCB using the appropriate equipment and parameters (temperature, pressure, time). Ensure complete coverage of all areas requiring cleaning.

-

Rinsing (aqueous only): If using aqueous or semi-aqueous cleaning, rinse the PCB thoroughly with deionized water to remove any remaining detergent or solvent residues. Minimize the time between washing and rinsing to prevent re-deposition of contaminants.

-

Drying: Remove all moisture from the PCB using filtered compressed air, a heat oven, or other drying method. Ensure the board is completely dry before further processing.

-

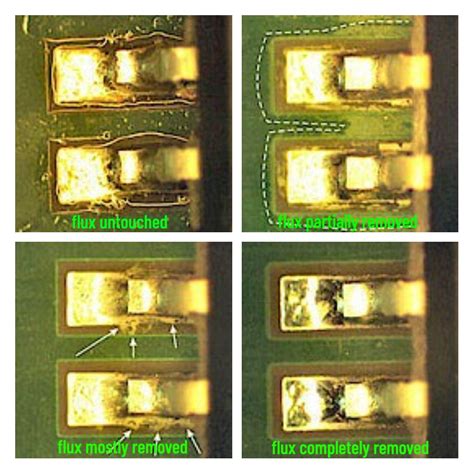

Post-cleaning inspection: Visually inspect the PCB again to verify complete removal of flux residues and any other contaminants. Additional testing such as ionic contamination or surface insulation resistance (SIR) testing may be performed depending on quality requirements.

Some best practices for PCB flux removal include:

- Choose the cleaning chemistry and method that is optimized for the specific type of flux and PCB design.

- Control the cleaning parameters (temperature, concentration, exposure time) to ensure effective removal without damaging the PCB.

- Use high-quality, electronics-grade solvents and DI water to minimize introduction of new contaminants.

- Regularly maintain and clean the cleaning equipment to prevent cross-contamination.

- Establish clear criteria for cleanliness and use appropriate test methods to verify cleaning effectiveness.

FAQ

1. Can I use isopropyl alcohol to remove water-soluble flux?

While isopropyl alcohol (IPA) is effective at dissolving rosin-based fluxes, it is not recommended for cleaning water-soluble flux residues. Water-soluble fluxes are designed to be removed with water and using IPA can actually make the residues harder to clean. Stick to warm DI water with a saponifier for cleaning water-soluble flux.

2. Is it necessary to clean no-clean flux residues?

In most cases, no-clean flux residues are designed to be left on the PCB without causing any long-term reliability issues. However, some manufacturers still choose to remove no-clean residues for several reasons:

- To enhance visual inspection of solder joints

- To improve adhesion of conformal coatings or potting compounds

- To meet specific cleanliness requirements for high-reliability applications

- To prevent any chance of the flux residues interfering with electronic functions

If removal of no-clean flux residues is desired, a mild solvent or aqueous cleaning process can be used.

3. What are some common cleaning defects and how can they be prevented?

Some common cleaning defects that can occur during PCB flux removal include:

-

Incomplete removal of flux residues: Can be caused by insufficient cleaning time, temperature or agitation. Ensure cleaning parameters are optimized and all areas of the PCB are adequately exposed to the cleaning chemistry.

-

White residue: Can be caused by using hard tap water or contaminated water for aqueous cleaning. Always use high-quality DI water and regularly check the water quality.

-

Corrosion: Can be caused by using overly aggressive cleaning chemistries or inadequate rinsing. Choose cleaning chemistries that are compatible with the metals on the PCB and ensure thorough rinsing to remove any remaining cleaners.

-

Electrical failures: Can be caused by moisture ingress or ESD damage during cleaning. Ensure the PCB is completely dried after cleaning and use ESD-safe equipment and handling procedures.

4. How do I know if my PCBs are clean enough?

The cleanliness level required for a PCB depends on the specific application and reliability requirements. Some common methods for measuring PCB cleanliness include:

-

Visual inspection: Examination under magnification to look for any visible flux residues, particulates or other contaminants.

-

Ionic contamination testing: Measures the concentration of ionic species on the PCB surface using a conductivity meter. Typical acceptable levels are less than 10 μg/in² NaCl equivalent.

-

Surface insulation resistance (SIR) testing: Measures the electrical resistance between conductors on the PCB surface. Provides an indication of the presence of conductive contaminants.

-

FTIR analysis: Fourier transform infrared spectroscopy can identify specific chemical compounds on the PCB surface.

Establish the appropriate cleanliness criteria for your products and use a combination of test methods to verify cleaning effectiveness.

5. Can I reuse my cleaning solvents?

Reusing cleaning solvents can be a cost-effective and environmentally responsible option, but it must be done carefully to avoid contaminating the PCBs. Solvents should be regularly tested for contamination and replaced when necessary. Filtration and distillation systems can be used to extend the life of cleaning solvents.

Some solvents, such as terpenes and glycol ethers, are more easily recyclable than others. Check with your solvent supplier for recommendations on reuse and recycling.

When reusing aqueous cleaning solutions, it is important to regularly monitor the concentration of detergent and replenish as needed to maintain cleaning effectiveness. The water should also be filtered and deionized to remove any dissolved contaminants.

Proper maintenance of cleaning equipment, including regular cleaning and replacement of filters, is also critical for successful solvent reuse.

In conclusion, removing flux residues is a critical step in PCB assembly to ensure reliability and performance. The specific cleaning method and chemistry should be chosen based on the type of flux and the cleanliness requirements for the application. Proper cleaning procedures and regular testing can help prevent cleaning defects and extend the life of cleaning materials. By following best practices and staying up to date with the latest cleaning technologies, manufacturers can ensure their PCBs are consistently clean and free of harmful contaminants.

Leave a Reply