Understanding the SMT Ordering Process

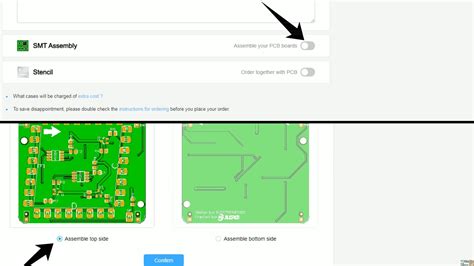

The SMT ordering process involves several steps, each requiring specific information and files to ensure accuracy and efficiency. The main stages of the process include:

- Requesting a quote

- Providing the necessary files and information

- Reviewing and confirming the quote

- Placing the order

- Tracking the order and manufacturing progress

To ensure a smooth and successful ordering experience, it is crucial to understand the requirements and best practices for each stage.

Essential Files for SMT Ordering

When ordering SMT assembly services, providing the following files is essential for accurate quoting and efficient manufacturing:

Bill of Materials (BOM)

The BOM is a comprehensive list of all components required for your PCB Assembly. It should include the following information for each component:

- Reference designator

- Manufacturer part number

- Description

- Quantity

- Package type

- Any additional notes or requirements

Providing an accurate and complete BOM is crucial for ensuring the correct components are sourced and used in the assembly process.

Gerber Files

Gerber files are the industry standard for PCB design data exchange. They contain essential information about the PCB layout, including:

- Copper layers

- Solder mask

- Silkscreen

- Drill data

Submitting high-quality, error-free Gerber files is critical for accurate PCB fabrication and assembly.

Pick and Place Files

Pick and place files, also known as centroid files or XY files, provide the coordinates for each component on the PCB. These files are used by the pick and place machine to accurately position components during the assembly process. Common formats for pick and place files include:

- .csv

- .txt

- .xls

Ensure that your pick and place files are generated correctly and match your PCB design to avoid assembly errors.

Assembly Drawings

Assembly drawings provide a visual representation of the PCB assembly, including component placement, orientation, and any special instructions. These drawings help the assembly team understand the layout and ensure accurate assembly. Assembly drawings should include:

- Board dimensions

- Component locations and orientations

- Any special handling or assembly requirements

Clear and detailed assembly drawings can help prevent misinterpretations and assembly mistakes.

Providing Accurate Information for SMT Ordering

In addition to the necessary files, providing accurate and complete information is essential for successful SMT ordering. Key information to include:

Quantity and Lead Time

Clearly specify the quantity of PCBs required and your desired lead time. This information helps the SMT assembly provider plan their production schedule and ensure timely delivery.

PCB Specifications

Provide detailed PCB specifications, including:

- Board material (e.g., FR4, high-temperature, flexible)

- Board thickness

- Copper weight

- Surface finish (e.g., HASL, ENIG, OSP)

- Any special requirements (e.g., impedance control, controlled dielectric)

Accurate PCB specifications ensure that the fabricated boards meet your design requirements and are compatible with the assembly process.

Component Specifications

Include any specific component requirements, such as:

- Tolerance

- Temperature rating

- RoHS compliance

- Moisture sensitivity level (MSL)

Clearly communicating component specifications helps the SMT assembly provider source the correct components and handle them appropriately during the assembly process.

Testing and Quality Control Requirements

Specify any testing and quality control requirements for your PCB assembly, such as:

- In-circuit testing (ICT)

- Flying probe testing

- Functional testing

- X-ray inspection

- Visual inspection criteria

Defining your testing and quality control expectations ensures that the finished products meet your standards and performance requirements.

Best Practices for SMT Ordering

To further optimize your SMT ordering process and ensure successful outcomes, consider the following best practices:

Use a Consistent File Naming Convention

Adopt a clear and consistent file naming convention for all your SMT ordering files. This practice helps avoid confusion and ensures that the correct files are used throughout the process. For example:

- ProjectName_BOM_RevisionNumber.xlsx

- ProjectName_Gerber_RevisionNumber.zip

- ProjectName_PickAndPlace_RevisionNumber.csv

- ProjectName_AssemblyDrawing_RevisionNumber.pdf

Communicate Special Requirements Early

If your PCB assembly has any special requirements, such as unique components, non-standard packaging, or specific testing needs, communicate these requirements early in the ordering process. This allows the SMT assembly provider to assess feasibility, plan accordingly, and provide accurate quotes.

Review and Verify Files Before Submitting

Before submitting your files for SMT ordering, thoroughly review and verify them for accuracy and completeness. Ensure that your BOM, Gerber files, pick and place files, and assembly drawings are up-to-date and error-free. Double-check that all files match your latest PCB design revision.

Establish Clear Communication Channels

Maintain clear and open communication with your SMT assembly provider throughout the ordering process. Provide a designated point of contact within your organization to handle any questions or issues that may arise. Promptly respond to requests for clarification or additional information to keep the process moving forward smoothly.

Plan for Potential Revisions and Changes

Be prepared for potential revisions or changes during the SMT ordering process. If design modifications are required, promptly update all relevant files and communicate the changes to your SMT assembly provider. Ensure that any revised files are clearly identified with updated revision numbers to avoid confusion.

Frequently Asked Questions (FAQ)

- What is the difference between Gerber files and pick and place files?

-

Gerber files contain information about the PCB layout, including copper layers, solder mask, and drill data. Pick and place files provide the coordinates for component placement on the PCB.

-

Can I submit my BOM in a PDF format?

-

While it is possible to submit a BOM in PDF format, it is recommended to use an editable format such as .xlsx or .csv. This allows for easier data extraction and reduces the risk of errors during the quoting and ordering process.

-

What should I do if I have a custom or non-standard component in my design?

-

If your design includes a custom or non-standard component, provide as much information as possible about the component, including manufacturer data sheets, dimensions, and any special handling requirements. Communicate this information early in the ordering process to ensure compatibility and availability.

-

How can I ensure that my PCB assembly meets my quality standards?

-

Clearly communicate your quality control requirements and testing expectations to your SMT assembly provider. Discuss the available testing options and establish an inspection and acceptance criteria for your PCB assembly. Maintaining open communication throughout the process helps ensure that your quality standards are met.

-

What is the typical lead time for SMT assembly?

- Lead times for SMT assembly can vary depending on factors such as PCB complexity, component availability, and the SMT assembly provider’s workload. Typical lead times range from a few days to several weeks. To ensure timely delivery, provide your desired lead time during the ordering process and communicate any urgent requirements to your SMT assembly provider.

Conclusion

Accurate and complete SMT ordering is essential for achieving high-quality PCB assemblies and efficient manufacturing processes. By providing the necessary files, such as the BOM, Gerber files, pick and place files, and assembly drawings, along with accurate information about quantities, specifications, and requirements, you can streamline the ordering process and minimize the risk of errors.

Implementing best practices, such as using consistent file naming conventions, communicating special requirements early, and thoroughly reviewing files before submission, further enhances the SMT ordering experience. By establishing clear communication channels and being prepared for potential revisions, you can collaborate effectively with your SMT assembly provider and ensure successful outcomes.

Remember, investing time and effort into accurate and detailed SMT ordering pays off in the form of faster quotes, smoother manufacturing, and higher-quality end products. By following the guidelines and best practices outlined in this article, you can navigate the SMT ordering process with confidence and achieve optimal results for your PCB assembly projects.

Leave a Reply