Rogers RT/duroid 5880 is a high-performance circuit board material that has become increasingly popular in recent years. This material is made up of a woven fiberglass cloth and a polytetrafluoroethylene (PTFE) composite substrate, which gives it excellent electrical properties. RT/duroid 5880 is known for its low dielectric constant, low loss tangent, and high thermal conductivity, making it ideal for high-frequency applications.

One of the key benefits of RT/duroid 5880 is its ability to handle high-frequency signals without significant signal loss. This makes it an ideal material for use in applications such as microwave antennas, satellite communications, and radar systems. Additionally, RT/duroid 5880 has a high thermal conductivity, which helps dissipate heat generated by high-power applications.

Another advantage of RT/duroid 5880 is its mechanical stability. The woven fiberglass cloth provides excellent dimensional stability, which means that the material does not expand or contract significantly with changes in temperature or humidity. This makes it an ideal material for use in applications where stability is critical, such as in aerospace and defense industries. Overall, RT/duroid 5880 is a versatile and reliable material that offers excellent electrical, mechanical, and thermal properties, making it an ideal choice for a wide range of high-performance applications.

Physical Properties of Rogers RT/Duroid 5880

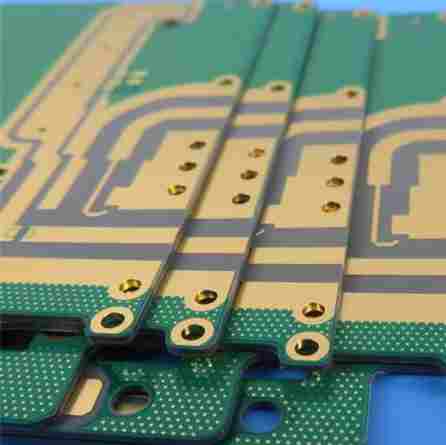

Rogers RT/Duroid 5880 is a high-performance laminate material that is widely used in the manufacturing of printed circuit boards (PCBs). This material is known for its excellent electrical and mechanical properties, making it a popular choice for applications that require high-frequency performance and reliability.

Here are some of the key physical properties of Rogers RT/Duroid 5880:

-

Dielectric constant: The dielectric constant of Rogers RT/Duroid 5880 is typically around 2.2, which is relatively low compared to other high-frequency PCB materials. This low dielectric constant makes it an ideal choice for applications that require low-loss performance.

-

Loss tangent: The loss tangent of Rogers RT/Duroid 5880 is typically around 0.0009, which is also relatively low compared to other high-frequency PCB materials. This low loss tangent makes it an ideal choice for applications that require high-frequency performance.

-

Thermal conductivity: The thermal conductivity of Rogers RT/Duroid 5880 is typically around 0.5 W/mK, which is relatively low compared to other high-frequency PCB materials. This low thermal conductivity can be beneficial in some applications where heat dissipation is not a major concern.

-

Coefficient of thermal expansion (CTE): The CTE of Rogers RT/Duroid 5880 is typically around 17 ppm/°C, which is relatively low compared to other high-frequency PCB materials. This low CTE can be beneficial in some applications where dimensional stability is important.

-

Tensile strength: The tensile strength of Rogers RT/Duroid 5880 is typically around 14,000 psi, which is relatively high compared to other high-frequency PCB materials. This high tensile strength makes it an ideal choice for applications that require mechanical stability.

Overall, Rogers RT/Duroid 5880 is a high-performance PCB material that offers excellent electrical and mechanical properties. Its low dielectric constant and loss tangent make it an ideal choice for high-frequency applications, while its high tensile strength and low CTE make it a reliable choice for applications that require mechanical stability.

Manufacturing Process

Rogers RT/duroid 5880 is a high-performance circuit board material that is used in a wide range of applications. The manufacturing process for this material is complex and involves several steps.

The first step in the manufacturing process is to mix the resin and the glass fibers. The resin is mixed with a catalyst and then combined with the glass fibers. The resulting mixture is then heated and pressed into sheets.

Once the sheets have been formed, they are cut to the required size and shape. The edges of the sheets are then cleaned and smoothed to ensure that there are no rough spots or jagged edges.

The next step in the manufacturing process is to apply the copper foil to the surface of the sheets. The copper foil is applied using a special adhesive that is designed to bond the copper to the surface of the sheets.

After the copper foil has been applied, the sheets are then laminated together. This is done by stacking the sheets on top of each other and then applying heat and pressure to bond them together.

Once the sheets have been laminated together, the circuit patterns are then etched onto the surface of the copper foil using a special chemical process. This process removes the copper from the areas where the circuit patterns are not required, leaving behind the required circuit patterns.

Finally, the finished circuit boards are inspected and tested to ensure that they meet the required specifications.

Overall, the manufacturing process for Rogers RT/duroid 5880 is complex and requires a high degree of precision and expertise. However, the resulting circuit boards are of a very high quality and are widely used in a variety of applications.

Applications of Rogers RT/Duroid 5880

Telecommunications

Rogers RT/Duroid 5880 is widely used in the telecommunications industry due to its high-frequency properties. The low dielectric constant of 2.2 and low loss tangent of 0.0009 make it an ideal material for high-frequency applications. This material is used in the design of high-speed digital and analog circuits, antennas, and power amplifiers for wireless communication systems. It is also used in radar systems, satellite communication systems, and microwave communication systems.

Aerospace

Rogers RT/Duroid 5880 is also used in the aerospace industry due to its excellent mechanical properties and high-temperature stability. Its low moisture absorption and high resistance to chemicals make it an ideal material for aerospace applications. It is used in the design of radomes, antennas, and other electronic components for satellites, spacecraft, and other aerospace applications.

Automotive

Rogers RT/Duroid 5880 is used in the automotive industry for radar systems, collision avoidance systems, and other high-frequency applications. Its low dielectric constant and low loss tangent make it an ideal material for automotive radar systems. It is also used in the design of high-speed digital circuits for automotive electronics.

In summary, Rogers RT/Duroid 5880 is a versatile material that finds applications in various industries. Its high-frequency properties, excellent mechanical properties, and high-temperature stability make it an ideal material for telecommunications, aerospace, and automotive applications.

Advantages of Rogers RT/Duroid 5880

Rogers RT/Duroid 5880 is a high-performance laminate material that is widely used in the RF and microwave industry. This laminate material has several advantages over other materials, making it a popular choice for many applications.

Low Dielectric Loss

One of the main advantages of Rogers RT/Duroid 5880 is its low dielectric loss. This means that it has a low amount of energy lost as heat when an electromagnetic wave passes through it. This is important for high-frequency applications because it helps to reduce signal attenuation and improve signal integrity.

High Thermal Stability

Another advantage of Rogers RT/Duroid 5880 is its high thermal stability. This means that it can withstand high temperatures without losing its electrical properties. This is important for applications where the material is exposed to high temperatures, such as in aerospace and defense applications.

Consistent Electrical Properties

Rogers RT/Duroid 5880 also has consistent electrical properties, which means that it performs consistently across different frequencies and temperatures. This is important for applications where precise electrical performance is required, such as in microwave filters and antennas.

Low Moisture Absorption

Finally, Rogers RT/Duroid 5880 has low moisture absorption, which means that it is less likely to absorb moisture from the environment. This is important for applications where the material is exposed to high humidity or moisture, such as in outdoor applications.

Overall, Rogers RT/Duroid 5880 is a high-performance laminate material that offers several advantages over other materials. Its low dielectric loss, high thermal stability, consistent electrical properties, and low moisture absorption make it a popular choice for many applications in the RF and microwave industry.

Limitations of Rogers RT/Duroid 5880

Despite its many advantages, Rogers RT/Duroid 5880 has some limitations that should be considered when choosing a material for your project.

Limited Frequency Range

One of the main limitations of Rogers RT/Duroid 5880 is its limited frequency range. This material is designed for use in high-frequency applications, but it may not be suitable for use in extremely high-frequency applications. In general, the frequency range of Rogers RT/Duroid 5880 is limited to around 40 GHz.

High Cost

Another limitation of Rogers RT/Duroid 5880 is its high cost. This material is more expensive than many other high-frequency circuit board materials on the market. This cost can be a significant factor for projects with tight budgets.

Limited Availability

Rogers RT/Duroid 5880 is not as widely available as some other circuit board materials. This can make it difficult to find suppliers or to get the material in a timely manner. Additionally, because it is a specialized material, it may not be stocked by all suppliers.

Difficult to Work With

Finally, Rogers RT/Duroid 5880 can be difficult to work with. This material requires specialized equipment and techniques for cutting, drilling, and shaping. It can also be difficult to solder, which can make it challenging to use in certain applications.

Overall, while Rogers RT/Duroid 5880 has many advantages, it is important to consider its limitations before choosing it for your project.

Comparison with Other Materials

When compared to other materials, Rogers RT/duroid 5880 stands out in terms of its unique properties and characteristics. Here are some of the key differences between Rogers RT/duroid 5880 and other common materials used in the industry:

Rogers RT/duroid 5880 vs. FR-4

FR-4 is a commonly used material in the industry due to its low cost and good electrical properties. However, when compared to Rogers RT/duroid 5880, FR-4 falls short in terms of its high-frequency performance. Rogers RT/duroid 5880 has a much lower dielectric constant and loss tangent, making it a better choice for high-frequency applications.

Rogers RT/duroid 5880 vs. PTFE

PTFE (polytetrafluoroethylene) is another material that is commonly used in high-frequency applications. While PTFE has similar electrical properties to Rogers RT/duroid 5880, it is more expensive and more difficult to process. Rogers RT/duroid 5880, on the other hand, is easier to process and has a lower cost of ownership.

Rogers RT/duroid 5880 vs. Ceramic Substrates

Ceramic substrates are often used in high-power applications due to their high thermal conductivity. However, when it comes to high-frequency applications, ceramic substrates fall short in terms of their dielectric constant and loss tangent. Rogers RT/duroid 5880, on the other hand, has a much lower dielectric constant and loss tangent, making it a better choice for high-frequency applications.

In conclusion, Rogers RT/duroid 5880 offers unique properties that make it an ideal choice for high-frequency applications. While other materials may be suitable for certain applications, Rogers RT/duroid 5880 stands out in terms of its electrical properties, ease of processing, and cost-effectiveness.

Future Developments

As technology continues to evolve, so too does the demand for high-performance materials like Rogers RT/duroid 5880. The company is committed to staying at the forefront of innovation in the field of circuit board materials, and is constantly working to develop new and improved products.

One area of focus for Rogers is the development of materials that can operate at even higher frequencies than RT/duroid 5880. The company has already made significant strides in this area, with products like RT/duroid 6035HTC and RT/duroid 6202LM, which are optimized for use in high-frequency applications.

Another area of focus for Rogers is the development of materials that are more environmentally friendly. The company recognizes the importance of sustainability and is committed to reducing its environmental impact. To this end, Rogers has developed materials like RT/duroid 5880LZ and RT/duroid 6002, which are halogen-free and have low levels of volatile organic compounds.

Overall, the future looks bright for Rogers RT/duroid 5880 and the company’s other high-performance materials. With a commitment to innovation and sustainability, Rogers is well-positioned to continue meeting the needs of the electronics industry for years to come.

Leave a Reply