The Rogers RO3200 is a versatile and high-performance spectrum analyzer that can accommodate a wide range of applications. It is designed to provide accurate and reliable measurements of RF signals, making it an essential tool for engineers and technicians working in the telecommunications, aerospace, defense, and other industries.

With its advanced features and capabilities, the Rogers RO3200 is capable of measuring signals with high accuracy and resolution, making it ideal for demanding applications. Its frequency range of up to 26.5 GHz, coupled with its high dynamic range and low noise floor, ensures that it can capture even the weakest signals with ease. Additionally, its intuitive user interface and comprehensive analysis tools make it easy to use and interpret the results.

Rogers RO3200 Overview

The Rogers RO3200 is a high-frequency circuit material that is designed for use in applications that require excellent electrical performance. This material is made from a ceramic-filled, woven-glass-reinforced PTFE composite, which gives it a low dielectric constant and a low loss tangent.

One of the key benefits of the Rogers RO3200 is its ability to maintain its electrical properties over a wide range of temperatures. This makes it ideal for use in applications that require high performance in extreme environments. Additionally, this material has excellent dimensional stability, which means that it can maintain its shape and size even when exposed to high temperatures and harsh conditions.

The Rogers RO3200 is also known for its high mechanical strength and durability. This material is resistant to impact, abrasion, and chemical attack, which makes it ideal for use in applications that require long-term reliability and performance.

In terms of electrical performance, the Rogers RO3200 has a dielectric constant of 3.02 and a loss tangent of 0.0013 at 10 GHz. These values make it an excellent choice for applications that require low loss and high frequency performance. Additionally, this material has a thermal conductivity of 0.5 W/mK, which makes it an effective heat sink for high-power applications.

Overall, the Rogers RO3200 is a high-performance circuit material that is ideal for use in a wide range of applications. Its excellent electrical and mechanical properties, combined with its ability to maintain performance over a wide range of temperatures, make it a popular choice for designers and engineers who require high reliability and performance in their applications.

Key Features

High Frequency Performance

The Rogers RO3200 circuit material is specifically designed for high frequency applications. It has a low loss tangent and high thermal conductivity which makes it ideal for use in high frequency circuits. The material has a low dielectric constant and a low dissipation factor which helps to reduce signal loss and improve signal integrity.

Thermal Conductivity

The Rogers RO3200 material has a high thermal conductivity which helps to dissipate heat generated by high power circuits. This is important for high frequency circuits as they tend to generate more heat than lower frequency circuits. The high thermal conductivity of the material helps to improve the reliability and performance of the circuit.

Dielectric Constant

The Rogers RO3200 material has a low dielectric constant which makes it ideal for use in high frequency circuits. The low dielectric constant helps to reduce signal loss and improve signal integrity. The material also has a low dissipation factor which helps to further reduce signal loss.

In summary, the Rogers RO3200 circuit material is designed for high frequency applications and has key features such as low loss tangent, high thermal conductivity, low dielectric constant, and low dissipation factor. These features make it an ideal choice for high frequency circuits that require high performance and reliability.

Applications of Rogers RO3200

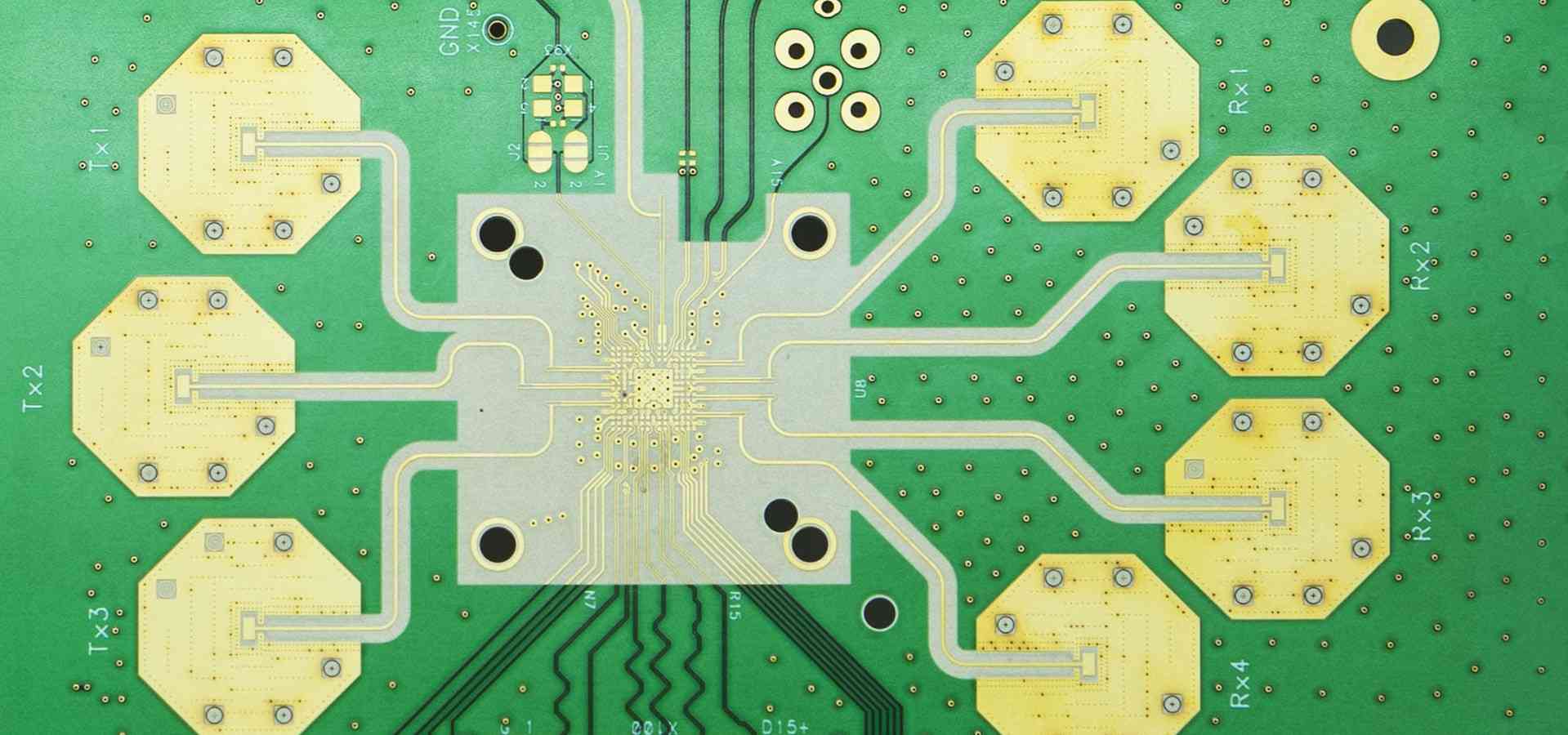

Antennas

Rogers RO3200 is a high-performance material that is widely used in the design of antennas. Its excellent dielectric properties, low loss tangent, and uniformity make it an ideal choice for high-frequency applications. The material is suitable for use in both patch and microstrip antennas. RO3200 is also used in the design of antennas for wireless communication systems, including Wi-Fi, Bluetooth, and cellular networks.

Microwave Circuits

RO3200 is a popular choice for the design of microwave circuits due to its low dielectric constant and low loss tangent. The material is suitable for use in microwave filters, power dividers, and amplifiers. The low loss tangent of RO3200 ensures that the signal loss is minimal, making it an ideal choice for high-frequency applications. The material is also known for its excellent dimensional stability, which is important in the manufacture of microwave components.

RFID Tags

RFID tags are used in a wide range of applications, including inventory management, asset tracking, and access control. Rogers RO3200 is an excellent choice for the design of RFID tags due to its excellent dielectric properties and low loss tangent. The material is suitable for use in both passive and active RFID tags. RO3200 is also known for its excellent thermal stability, making it an ideal choice for use in harsh environments.

In summary, Rogers RO3200 is a versatile material that is widely used in the design of antennas, microwave circuits, and RFID tags. Its excellent dielectric properties, low loss tangent, and uniformity make it an ideal choice for high-frequency applications.

Handling and Processing

Material Storage

When it comes to handling and processing Rogers RO3200, proper storage of the material is crucial. The material should be stored in a dry and cool environment, away from direct sunlight and moisture. It is recommended to store the material in its original packaging until ready to use.

Machining

Rogers RO3200 is a high-performance material that requires specialized machining techniques. It is important to use sharp tools and appropriate cutting speeds to avoid delamination and other issues. Machining should be done in a well-ventilated area, and protective gear, such as gloves and a respirator, should be worn to avoid inhaling dust particles.

Assembly

When assembling parts made from Rogers RO3200, it is important to use compatible adhesives and to follow the manufacturer’s recommended curing times and temperatures. The material should be cleaned thoroughly before bonding to ensure proper adhesion.

In conclusion, handling and processing Rogers RO3200 requires careful attention to detail and specialized techniques. With proper storage, machining, and assembly, this high-performance material can be used to create durable and reliable parts.

Comparison with Other Materials

When it comes to high-frequency circuit materials, there are several options available on the market. Here, we will compare Rogers RO3200 with other commonly used materials.

One of the most popular materials used in high-frequency applications is FR-4. While it is a cost-effective option, it has limitations in terms of performance. FR-4 has a lower dielectric constant and higher loss tangent compared to RO3200, which can result in signal loss and reduced performance at higher frequencies.

Another commonly used material is polytetrafluoroethylene (PTFE). PTFE has a lower dielectric constant and loss tangent than FR-4, making it a better option for high-frequency applications. However, it is more expensive than FR-4 and has a lower thermal conductivity than RO3200.

Ceramic materials are also used in high-frequency applications. They have a high dielectric constant and low loss tangent, making them suitable for high-frequency applications. However, they are brittle and can be difficult to manufacture in complex shapes.

Compared to these materials, RO3200 offers a balance of cost-effectiveness, performance, and ease of manufacturing. With a high dielectric constant and low loss tangent, it provides excellent performance at high frequencies. Its thermal conductivity is also higher than PTFE, making it suitable for applications that require efficient heat dissipation. Overall, RO3200 is a versatile and reliable choice for high-frequency circuit applications.

Purchasing and Availability

The Rogers RO3200 is a popular material for high-frequency circuit boards due to its low dielectric constant and loss, high thermal conductivity, and excellent dimensional stability. This material is widely available from various manufacturers, including Rogers Corporation, the original developer of the RO3200.

The RO3200 is available in a range of thicknesses, typically ranging from 0.005″ to 0.250″. The standard sheet size is 24″ x 36″, but other sizes are also available upon request. The material is typically sold in sheets or panels, but it can also be purchased in custom shapes and sizes.

The price of the RO3200 varies depending on the thickness, size, and quantity ordered. Generally, the larger the order, the lower the price per unit. Customers can purchase the RO3200 directly from Rogers Corporation or through authorized distributors and resellers.

Overall, the Rogers RO3200 is a widely available and cost-effective material for high-frequency circuit boards. Its availability from multiple sources and in various sizes and shapes makes it a versatile option for a range of applications.

Leave a Reply