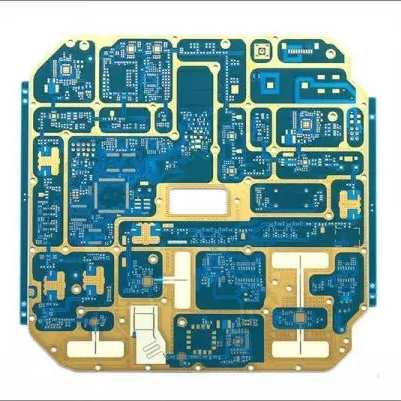

Rogers RO3035 is a high-frequency laminate material that has been designed for use in multilayer printed circuit boards (PCBs). It is a popular choice among designers due to its excellent electrical properties, low dielectric constant, and low loss tangent. The material is ideal for use in high-speed digital and RF applications, where signal integrity and reliability are critical.

The Rogers RO3035 laminate material is made up of woven glass fabric impregnated with a thermoset resin system. It has a dielectric constant of 3.5 and a dissipation factor of 0.003 at 10 GHz. The material also has a low coefficient of thermal expansion, making it suitable for use in applications that require high reliability over a wide temperature range.

One of the key benefits of using Rogers RO3035 is its ability to provide consistent electrical performance across a range of frequencies. This makes it an ideal choice for applications such as microwave and millimeter-wave circuits, where signal integrity is critical. In addition, the material has excellent thermal stability, which means that it can maintain its electrical properties even under high-temperature conditions.

Overview of Rogers RO3035

Rogers RO3035 is a high-frequency circuit material that is used in a variety of applications, including automotive radar, satellite communications, and wireless infrastructure. It is a thermoset material that is designed to have low loss and high thermal stability, making it an excellent choice for high-frequency applications.

One of the key features of Rogers RO3035 is its low loss. This means that it has a low level of attenuation, which allows signals to travel further without being degraded. This is particularly important in high-frequency applications where signal loss can be a significant issue.

Another important feature of Rogers RO3035 is its high thermal stability. This means that it can withstand high temperatures without degrading, which is important in applications where the material is exposed to high levels of heat. This also makes it an excellent choice for applications where the material is used in close proximity to heat-generating components.

Rogers RO3035 is available in a variety of thicknesses, ranging from 3 mils to 20 mils, which makes it suitable for a wide range of applications. It can also be supplied with a variety of copper thicknesses, which allows designers to optimize their designs for their specific application.

Overall, Rogers RO3035 is an excellent choice for high-frequency applications where low loss and high thermal stability are important. Its availability in a range of thicknesses and copper thicknesses also makes it a versatile material that can be used in a wide range of applications.

Key Features of Rogers RO3035

Rogers RO3035 is a high-frequency circuit material that offers excellent electrical performance and reliability. Here are some of its key features:

-

Low Dielectric Constant: Rogers RO3035 has a low dielectric constant of 3.5, which makes it ideal for high-frequency applications where signal loss must be minimized.

-

Low Loss Tangent: The material has a low loss tangent of 0.003 at 10 GHz, which ensures minimal signal loss and high signal integrity.

-

Stable Electrical Performance: Rogers RO3035 has a stable electrical performance over a wide range of frequencies, temperatures, and humidity levels.

-

High Thermal Conductivity: The material has a high thermal conductivity of 0.69 W/mK, which allows it to dissipate heat efficiently and ensures reliable performance even under high-power conditions.

-

Excellent Dimensional Stability: Rogers RO3035 has excellent dimensional stability, which means that it maintains its shape and size even under harsh environmental conditions.

-

Ease of Processing: The material is easy to process and can be machined, drilled, and routed using standard PCB fabrication techniques.

In summary, Rogers RO3035 is a high-performance circuit material that offers low dielectric constant, low loss tangent, stable electrical performance, high thermal conductivity, excellent dimensional stability, and ease of processing. These features make it an ideal choice for high-frequency and high-power applications that require reliable and efficient performance.

Technical Specifications

The Rogers RO3035 laminates are high-frequency circuit materials that have been designed to provide excellent electrical and mechanical performance. They are ideal for use in applications that require high-frequency performance, such as antennas, filters, and power amplifiers.

The following are the technical specifications of the Rogers RO3035 laminates:

-

Dielectric Constant (Dk): The Rogers RO3035 laminates have a dielectric constant of 3.5 ± 0.05. This makes them suitable for use in high-frequency applications, as they provide low loss and stable performance over a wide frequency range.

-

Loss Tangent (Df): The loss tangent of the Rogers RO3035 laminates is 0.0023 at 10 GHz. This low loss tangent ensures that the laminates provide excellent signal integrity and minimal signal distortion.

-

Thermal Coefficient of Dielectric Constant (TCDk): The thermal coefficient of dielectric constant of the Rogers RO3035 laminates is 15 ppm/°C. This ensures that the laminates provide stable electrical performance over a wide temperature range.

-

Thermal Conductivity: The thermal conductivity of the Rogers RO3035 laminates is 0.52 W/mK. This ensures that the laminates provide excellent heat dissipation, which is essential for high-power applications.

-

Glass Transition Temperature (Tg): The glass transition temperature of the Rogers RO3035 laminates is 180°C. This ensures that the laminates can withstand high-temperature processing and assembly operations.

-

Coefficient of Thermal Expansion (CTE): The coefficient of thermal expansion of the Rogers RO3035 laminates is 17 ppm/°C. This ensures that the laminates provide excellent dimensional stability over a wide temperature range.

In summary, the Rogers RO3035 laminates are high-performance circuit materials that provide excellent electrical and mechanical performance. They are ideal for use in high-frequency applications that require low loss, stable performance, and excellent heat dissipation.

Installation and Setup

Installing and setting up Rogers RO3035 is a straightforward process that can be completed by most users without any professional assistance. The following steps outline the process:

- Unpack the product and check whether all the components are present.

- Install the RO3035 module onto the PCB (Printed Circuit Board) using standard SMT (Surface Mount Technology) assembly techniques.

- Connect the module to the power supply and the antenna.

- Configure the module’s settings according to the user’s requirements using the provided software tool.

The module is compatible with most microcontrollers, and the software tool can be used to configure the module’s settings easily. The tool provides a user-friendly interface that allows users to configure the module’s output power, frequency, and other parameters.

The module has a compact size, and its low power consumption makes it an ideal choice for IoT (Internet of Things) applications. The module’s small form factor allows it to be integrated into a wide range of devices, including smart home appliances, wearables, and industrial equipment.

Overall, installing and setting up the Rogers RO3035 module is a simple and straightforward process that can be completed by most users. The module’s compatibility with most microcontrollers and its user-friendly software tool make it an ideal choice for IoT applications.

Performance Analysis

Frequency Response

The Rogers RO3035 laminate is a high-performance material that exhibits excellent frequency response characteristics. Its low dielectric constant of 3.5 and low loss tangent of 0.0035 make it an ideal choice for high-frequency applications. The material’s low loss tangent means that it has low signal attenuation, which is essential for maintaining signal integrity in high-speed digital and RF circuits.

Impedance Matching

Impedance matching is critical in high-frequency circuits to ensure maximum power transfer and minimize signal reflections. The Rogers RO3035 laminate has a tightly controlled dielectric constant and thickness, making it an excellent choice for impedance-controlled designs. The material’s high dimensional stability ensures that the impedance values remain consistent over a wide range of frequencies, making it ideal for use in high-speed digital and RF circuits.

Thermal Conductivity

The Rogers RO3035 laminate has excellent thermal conductivity, which is essential for dissipating heat generated by high-power electronic components. Its thermal conductivity is 0.69 W/mK, which is higher than many other high-frequency laminates. The material’s high thermal conductivity helps to prevent hotspots and ensures that the electronic components operate within their temperature limits.

In summary, the Rogers RO3035 laminate is an excellent choice for high-frequency applications that require low loss tangent, tight impedance control, and high thermal conductivity. Its excellent frequency response characteristics make it ideal for use in high-speed digital and RF circuits, while its high thermal conductivity ensures that it can dissipate heat generated by high-power electronic components.

Applications of Rogers RO3035

Rogers RO3035 is a high-frequency circuit material that is widely used in various applications. It is a high-performance thermoset laminate that offers excellent electrical and mechanical properties. Here are some of the common applications of Rogers RO3035:

Antennas

Rogers RO3035 is an ideal material for antennas due to its low loss tangent and high dielectric constant. It provides excellent antenna performance and is commonly used in the design of patch antennas, microstrip antennas, and other types of antennas. The material’s low loss tangent also helps to improve the efficiency of the antenna.

Power Amplifiers

Rogers RO3035 is commonly used in the design of high-frequency power amplifiers due to its excellent thermal stability and high thermal conductivity. The material’s low thermal coefficient of expansion helps to reduce stress on the components, which can lead to improved reliability and longer life.

Microwave Circuits

Rogers RO3035 is widely used in the design of microwave circuits due to its excellent electrical properties. The material’s high dielectric constant and low loss tangent make it an ideal substrate for high-frequency circuits. It is commonly used in the design of filters, couplers, and other types of microwave components.

Radar Systems

Rogers RO3035 is commonly used in the design of radar systems due to its excellent electrical properties and high thermal stability. The material’s low loss tangent and high dielectric constant make it an ideal substrate for high-frequency radar systems. It is commonly used in the design of radar antennas, radar receivers, and other types of radar components.

In conclusion, Rogers RO3035 is a high-performance circuit material that offers excellent electrical and mechanical properties. It is widely used in various applications, including antennas, power amplifiers, microwave circuits, and radar systems.

Maintenance and Care

To ensure optimal performance and longevity of your Rogers RO3035, it’s essential to follow proper maintenance and care guidelines. Here are some tips to help you keep your RO3035 in excellent working condition:

-

Regular Cleaning: Regularly clean the RO3035 with a soft cloth and a mild detergent. Avoid using abrasive cleaners or solvents that may damage the surface of the material.

-

Avoid Impact: The Rogers RO3035 is a delicate material that can crack or chip if dropped or hit with a hard object. Avoid impacts and handle the material with care.

-

Storage: Store the RO3035 in a dry, cool place, away from direct sunlight or heat sources. Avoid stacking or placing heavy objects on top of the material.

-

Avoid Chemicals: The Rogers RO3035 is susceptible to chemical damage, so avoid exposing it to harsh chemicals or solvents.

-

Inspect Regularly: Inspect the RO3035 regularly for any signs of damage or wear and tear. If you notice any cracks or chips, contact a professional to repair or replace the material.

Following these simple maintenance and care guidelines will help you keep your Rogers RO3035 in excellent working condition for years to come.

Safety Precautions

When working with Rogers RO3035, it is important to follow safety precautions to prevent any potential hazards. Here are some guidelines to keep in mind:

-

Wear protective gear: Always wear protective gear such as gloves, safety glasses, and a respirator when handling RO3035. This will help prevent skin and eye irritation, as well as inhalation of any dust or fumes.

-

Keep the area well-ventilated: RO3035 can emit fumes when heated or cut, so it is important to work in a well-ventilated area. Use a fume hood or ensure that the workspace has adequate air flow to prevent any potential health risks.

-

Store RO3035 properly: When not in use, store RO3035 in a cool, dry place away from direct sunlight and heat sources. This will help prevent any potential degradation of the material and maintain its quality.

-

Handle with care: RO3035 is a fragile material and can easily break or crack. Handle it with care to prevent any damage to the material or injury to yourself.

By following these safety precautions, you can ensure a safe and successful experience when working with Rogers RO3035.

Conclusion

Overall, Rogers RO3035 is a high-performance laminate material that offers excellent electrical properties, thermal stability, and reliability. It is a popular choice for high-frequency applications, including aerospace and defense, automotive, telecommunications, and medical devices.

One of the key benefits of RO3035 is its low dielectric loss, which enables it to maintain signal integrity even at high frequencies. It also has a low coefficient of thermal expansion, which means it can withstand temperature changes without cracking or warping.

RO3035 is compatible with a wide range of manufacturing processes, including drilling, routing, and laser cutting. It can be easily bonded with other materials using a variety of adhesives and surface treatments.

While RO3035 is a high-quality material, it is important to note that it may not be the best choice for every application. It is important to carefully consider the specific requirements of your project and consult with a materials expert to determine the best material for your needs.

In summary, Rogers RO3035 is a reliable and high-performance material that offers excellent electrical properties and thermal stability. It is a popular choice for high-frequency applications in a variety of industries and is compatible with a wide range of manufacturing processes.

Leave a Reply