Introduction

Rogers curamik Endurance delivers outstanding thermal management and reliability for the most demanding applications in aerospace, defense, telecommunications, energy, medical, and other high-performance industries. As a subsidiary of Rogers Corporation, curamik leverages over 190 years of material science innovation to develop ceramic substrate solutions that stand up to extreme conditions.

The curamik Endurance product line utilizes cutting-edge ceramic technology to provide:

- Thermal conductivity up to 260 W/mK

- High thermal shock resistance

- Low thermal expansion

- Hermetic sealing

- Excellent electrical insulation

With curamik Endurance substrates, engineers can push the performance envelope for avionics, radars, energy storage, downhole drilling, surgical devices, and other critical systems. This article will explore the key benefits and applications of curamik Endurance products.

Key Features of curamik Endurance Substrates

curamik Endurance sets the standard for performance and reliability in ceramic substrates. Some of the notable features include:

Superior Thermal Management

- Aluminum nitride material with thermal conductivity up to 260 W/mK

- Highly effective at dissipating heat from high-power components

- Reduces junction temperatures and thermal gradients

- Enables extended use at higher power levels

Robust Construction

- Can withstand extreme temperature swings up to 1000°C

- Resists cracking due to mechanical, thermal, and piezoelectric stresses

- High flexural strength >300 MPa

Hermetic Sealing

- Vacuum-tight enclosures with leakage rates <10−8 mbar L/s

- Protects sensitive components from harsh environments

- Enables high-temperature operation up to 1000°C

Electrical Insulation

- Volume resistivity >1014 Ohm cm

- Withstands high voltages up to 15kV

- Prevents current leakage and short circuits

Low Thermal Expansion

- X and Y CTE ~4.5 ppm/K

- Closely matched to silicon devices

- Absorbs thermal stresses and strains

High Thermal Shock Resistance

- Rapid heating/cooling cycles

- Prevents cracking due to mismatch stresses

- Enables operation in turbulent environments

Lightweight and Thin Construction

- Dense substrates with thin profiles down to 0.1 mm

- Facilitates weight savings

- Allows integration into compact devices

Target Applications

With its robust thermal and mechanical properties, curamik Endurance adds value across numerous high-performance industries:

Aerospace and Defense

- Radars, sensors, navigation, communications, and other avionics equipment

- Requires reliable operation under vibration, shock, altitude, temperature extremes

- Hermetic sealing protects against humidity, pressure, particles, etc.

Telecommunications

- High-power amplifiers, data transmission systems, 5G base stations

- Manages significant heat loads from RF power devices

- Withstands continuous 24/7 operation

Healthcare

- Surgical devices, diagnostics, imaging systems

- Dissipates heat from laser, x-ray, ultrasound, LED components

- Enables miniaturization of devices

- Biocompatible for implantation

Energy Storage

- Battery management systems for electric vehicles and grid storage

- Safely insulates and isolates high voltage circuitry >1000V

- Operates reliably in turbulent, high-temp battery environments

Oil/Gas Drilling

- Electronics for downhole drilling equipment

- Survives shock, vibration, and temperatures up to 175°C

- Hermetic sealing withstands high pressures

Additional Markets

- Electric vehicles, solar/wind power, rail, space exploration, security systems, and more.

curamik Endurance provides an enabling technology for pushing the limits across a diverse spectrum of applications.

curamik Endurance Product Platforms

curamik Endurance includes several product platforms tailored to different requirements:

curamik Endurance RBS

- Round ceramic substrates 50-100mm diameter

- Single/double-sided metalization

- Via diameters down to 0.15mm

- Thermal conductivity up to 260W/mK

curamik Endurance CBS

- Square ceramic substrates 50-150mm sides

- Openings and cutouts available

- Active and passive cooling options

- Volume production capable

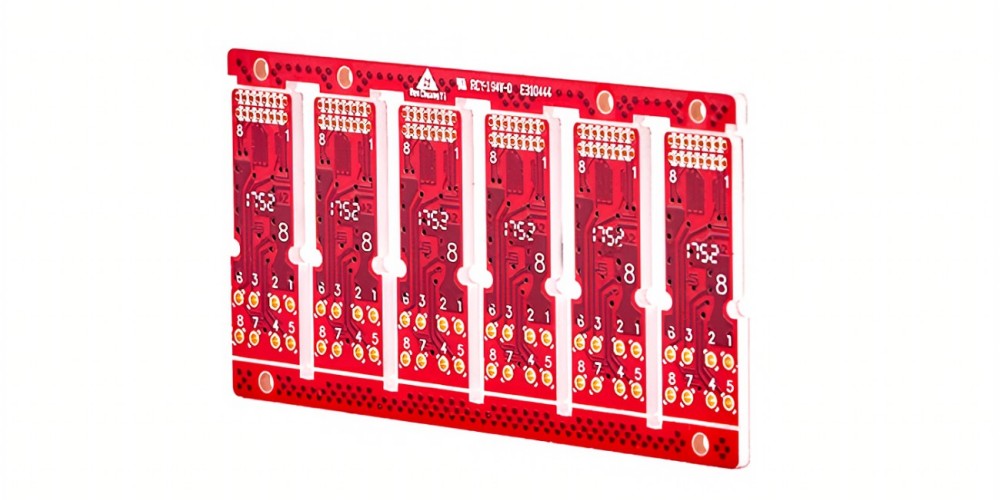

curamik Endurance RSS

- Rectangular substrates with high aspect ratios

- Down to 0.1mm thick

- Ultra-smooth surfaces <0.2μm Ra

- Lateral thermal conductivity >170W/mK

curamik Endurance CSS

- Cofired ceramic and metallic layers

- Complex 2D and 3D interconnects

- Integrated passive components

- Multi-substrate assemblies

curamik Endurance HMS

- Hermetic packaging including lids/frames

- Ultra-high hermeticity <10E-12 mbar l/s

- Glass/ceramic and ceramic/metal sealing

- Leadless solder preforms

This diverse portfolio enables curamik Endurance to meet requirements across a wide spectrum of electronics applications. Custom designs are also possible.

curamik Endurance Reliability

Reliability is paramount for electronics operating in critical applications and harsh environments. curamik Endurance delivers industry-leading quality:

- Stringent 100% in-process inspection

- High-sensitivity helium leak testing

- Real-time X-ray and optical metrology

- ISO 9001 and AS9100 certified manufacturing

- MIL-PRF-38534 Class H/K space-grade materials

- Traceability to lot/wafer level

curamik substrates exhibit extraordinarily low failure rates even under accelerated testing:

| Test Type | Conditions | Results |

|---|---|---|

| Highly Accelerated Stress Test | 130°C/85% RH, 20 atm pressure | No failures after 1000 hours |

| Temperature Cycling | -65°C to 175°C, 1000 cycles | No failures |

| Vibration | 20-2000Hz, 15g | No fractures after 12 hours |

| Mechanical Shock | 1000g | No fractures after 6000 shocks |

This level of reliability enables long service life in the most challenging operating environments. customers can have full confidence in curamik Endurance performance.

Partnering with curamik Endurance

curamik Endurance provides more than just world-class products – it delivers collaborative engineering support focused on customer success:

- Application analysis and thermal modeling

- Design optimization and rapid prototyping

- Reliability testing and qualification

- Supply chain management and logistics

- Lifecycle maintenance and obsolescence mitigation

With over 50 years in business and ceramic R&D expertise, curamik understands customer needs and how to deliver results. The company maintains an extensive network of sales and engineering resources ready to engage at any stage of a project.

curamik prioritizes technical partnerships based on trust, transparency, and shared risk/reward. This customer-centric approach enables innovative solutions that meet even the most demanding application requirements on time and budget.

Conclusion

For electronics that face punishing conditions and have zero room for failure, curamik Endurance delivers. The substrates provide industry-leading thermal management, hermetic sealing, and mechanical reliability for aerospace, defense, telecom, energy, medical, and other extreme environment applications.

With a diverse product portfolio and collaborative engineering support, curamik Endurance helps bring next-generation technologies successfully from design to deployment. Companies seeking a strategic ceramic substrate partner can rely on curamik Endurance solutions to give their mission-critical systems the enduring performance they demand.

Frequently Asked Questions

What makes curamik Endurance substrates unique?

curamik Endurance uses advanced aluminum nitride material technology to achieve thermal conductivity up to 260 W/mK, hermetic sealing to 10E-12 mbar l/s, high thermal shock resistance up to 1000°C, and other elite performance properties that surpass conventional ceramic substrates.

What are some typical applications for curamik Endurance?

Aerospace avionics, telecom base stations, downhole drilling electronics, battery systems, surgical devices, radars, and other electronics that must operate reliably under high heat loads, vibration, shock, and extreme temperatures.

How can curamik Endurance improve my product designs?

The curamik team provides collaborative engineering support to optimize designs. Superior thermal management enables higher power densities. Hermetic sealing protects against particles, moisture, and pressure. And high strength/reliability allows long service life.

Does curamik offer custom product development?

Yes, curamik engineers work closely with customers to create custom substrates tailored to unique requirements, including non-standard geometries, interconnects, integrated passives, and multi-substrate assemblies.

How can I get samples and quotes for curamik Endurance?

Contact a curamik sales representative via the website chat, email, or phone. The team will provide samples for design testing and detailed quotes for custom substrates. curamik aims to build long-term partnerships with customers.

Leave a Reply