Flexible and Customizable Heaters

Rogers Corporation’s ARLON Silicone Flexible Heater Substrates provide a customizable heating solution for a wide range of applications. These thin, flexible silicone rubber heaters can be produced in almost any 2D shape and size to meet unique heating requirements.

The silicone rubber material allows the substrate to be bent, twisted, and conformed while still maintaining heating uniformity, stability, and efficiency. The substrates feature printed silver conductors that function as the heating element. Rogers can customize the conductor pattern, watt density, and voltage to achieve the desired heating output.

Key Features

- Thin and lightweight – substrates are typically 0.015″ to 0.060″ thick

- Flexible – can be bent and conformed

- Customizable shape, size, and heating output

- Consistent, uniform heating across entire surface

- Can be bonded to other materials like metals, plastics, and fabrics

- Capable of rapid heat-up and cool down

- Operates on low voltage, typically less than 48V

Diverse Applications

The thin, adaptable nature of Rogers ARLON silicone rubber heaters allows them to be integrated into a wide range of products and processes:

- Medical devices – heating blankets, warming trays, incubators

- HVAC systems – duct heaters, fan heaters, electric heat pumps

- Automotive – heated seats, mirrors, and panels

- Consumer electronics – wearables, mobile devices, laptops

- Industrial – process heating, drum and mold heaters

- Food service – holding cabinets, food warmers

The customizability of the ARLON substrates enables engineers to design heaters optimized for their specific application requirements.

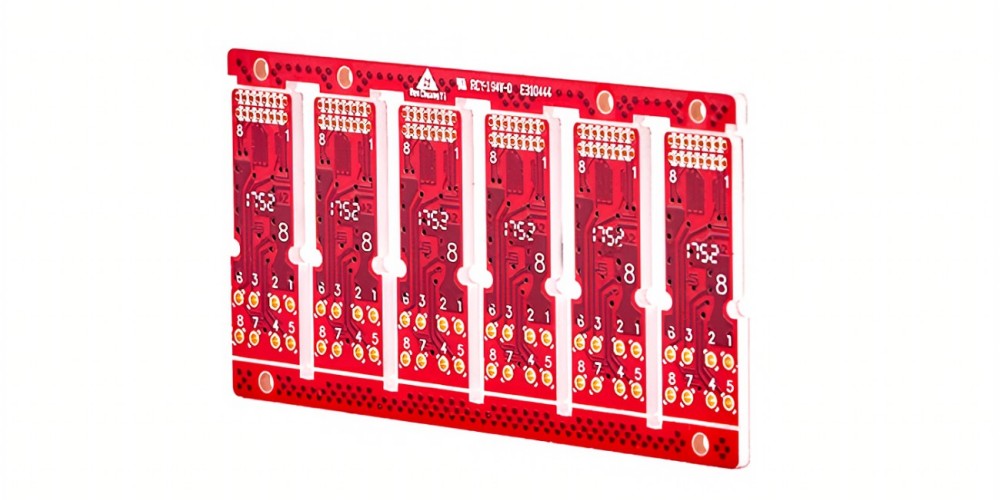

Heater Construction

The ARLON silicone heater construction consists of three layers:

- Silicone rubber – Provides a flexible, durable substrate. Can be fiberglass reinforced for extra robustness.

- Silver conductors – Printed electrical circuits that serve as the heating element. Custom conductor layouts allow tuning of watt density and heating uniformity.

- Dielectric overcoat – A thin silicone top coat that electrically isolates and protects the conductor layer. Also facilitates bonding.

Rogers leverages specialized manufacturing techniques like screen printing to efficiently produce these heaters in a wide range of geometries and sizes, from prototypes to high volume production.

Product Testing and Support

Rogers has over 50 years of experience developing and manufacturing flexible heaters. Their application engineers can provide design support and thermal modeling to help customers optimize heater performance.

The company utilizes state-of-the-art test facilities to validate key heater parameters like watt density, temperature uniformity, bend radius, and durability.Rogers also offers RoHS compliant and halogen free options to meet environmental regulations.

Frequently Asked Questions

What temperature range can ARLON heaters operate at continuously?

Most ARLON silicone rubbers can continuously withstand temperatures from -60°F to nearly 500°F. The max continuous use temp depends on heater materials and construction.

Can the heaters be bonded to other surfaces?

Yes, the ARLON silicone surface allows the heaters to be easily laminated or bonded to other materials using adhesives.

Are the heaters waterproof and weather resistant?

The silicone rubber construction provides excellent water, humidity, and chemical resistance. IP rating depend on electrical connections.

How long is the life cycle of a ARLON silicone heater?

Properly designed ARLON heaters can operate continuously for many years. Life is maximized by controlling max temperature and using within rated voltage.

Can the heaters be cut to size or shape?

Yes, ARLON heaters can be die cut or otherwise modified but this may impact heating performance and durability. Consulting Rogers is recommended.

Conclusion

Rogers ARLON silicone flexible heater substrates provide engineers with a highly customizable thermal solution. The thin, durable silicone heaters can be tailored to fit the exact size, shape, and heating requirements of new product designs in industries from medical to consumer electronics. Relying on decades of experience manufacturing flexible heaters, Rogers can support customers through the design process to create optimized solutions.

Leave a Reply