A radio frequency (RF) circulator is a non-reciprocal three-port passive device used to control the direction of signal flow in a circuit. It can isolate transmit and receive signals in duplexer applications and protect equipment from load mismatches in various microwave systems.

This article provides a comprehensive guide on RF circulator design covering:

- Operating principle

- Key parameters

- Circulator configurations

- Materials selection

- Electromagnetic design

- Prototyping and testing

By the end of this article, you will have a solid understanding of the circulator working mechanism, design considerations, and the overall process for developing a custom RF circulator.

How Does a RF Circulator Work?

A circulator uses a strong magnetic field and gyromagnetic effect to break Lorentz reciprocity and induce non-reciprocal transmission characteristics. The key operating principle is explained below:

Gyromagnetic Effect

Certain crystals like ferrites exhibit gyromagnetic behavior when subjected to a static magnetic field. It causes the material’s permeability tensor to become non-symmetric. This results in different propagation velocities for RF waves passing through the material in opposite directions.

Non-Reciprocal Phase Shift

When an RF signal enters port 1 of the circulator, the gyromagnetic material (ferrite) produces a non-reciprocal phase shift between the incident and reflected waves. This creates a standing wave pattern enabling the signal to transmit to port 2.

Port Isolation

When a signal enters port 2, the reflected and incident waves superimpose in phase, creating destructive interference. This prevents transmission from port 2 to 1, thereby isolating the ports.

Operating principle of a Y-junction ferrite circulator

Thus, the circulator non-reciprocal behavior enables unidirectional signal flow and port isolation for duplexing and matching applications in microwave systems.

Key Parameters for RF Circulator Design

The important electrical specifications that need to be defined when designing a circulator include:

- Center Frequency (fč) – The resonant frequency at which the circulator operates. It depends on the dimensions and ferrite material.

- Bandwidth (BW) – The range of frequencies over which the circulator maintains acceptable performance. It depends on ferrite material, magnetization, and matching.

- Insertion Loss (IL) – The signal power loss through the circulator. Needs to be minimized via impedance matching.

- Isolation (IS) – The power loss between isolated ports. Needs to be maximized by proper ferrite biasing.

- VSWR – The voltage standing wave ratio, a measure of match between the circulator and connected systems. Should be minimized.

- Power Handling – Maximum RF power the circulator can handle without excessive heating or saturation. Depends on ferrite material.

- Size – Physical dimensions can range from tiny microwave IC sizes to large waveguide devices.

These parameters guide the circulator design choices and trade-offs required to meet system requirements.

Common Circulator Configurations

Circulators are constructed in different configurations depending on power level, frequency range, and connectivity needs.

Y-Junction Circulator

A 3-port junction circulator has ports spaced 120° apart around a central ferrite disk for microwave frequencies. Compact stripline construction provides good match. Used for lower power levels up to tens of watts.

H-Plane Circulator

Ports are located on top of the ferrite disks. The magnetic field is parallel to the RF electric field. Larger devices used at UHF frequencies and power levels up to hundreds of watts.

E-Plane Circulator

Similar to H-plane but with magnetic field perpendicular to electric field. Handles higher power levels up to thousands of watts. Used for high power applications.

4-Port and 6-Port Circulators

Provide additional ports and routing configurations. Allow combining multiple duplexers/filters to a common antenna for complex microwave systems.

Material Selection for RF Circulators

The magnetic and dielectric materials used are key aspects governing circulator performance.

Ferrite Materials

These gyromagnetic materials enable the non-reciprocal behavior. Important characteristics are:

- Saturation magnetization (4πMs) – Limits max RF power handling. Should be high.

- Relative permittivity (εr) – Affects impedance matching. Values between 12 and 16 are common.

- Permeability (μ) – Impacts isolation and bandwidth. High μ gives widest bandwidth.

- Curie temperature (Tc) – Sets max operating temperature limit. Should exceed reqd. range.

Popular ferrite choices are YIG, lithium ferrites, and hexagonal ferrites, each with trade-offs between bandwidth, power handling, and cost.

Dielectrics

Dielectrics physically support the ferrite and transmission lines. Key characteristics are:

- Low dielectric constant to maintain impedance match

- High thermal conductivity for heat dissipation

- Compatible CTE with ferrites to avoid mechanical stress

- Must withstand operating temperatures without degradation

Alumina, aluminum nitride, and PTFE composites are commonly used dielectric partners with ferrite materials in circulator assemblies.

Electromagnetic Design Optimization

The physical dimensions and electromagnetic characteristics must be co-optimized to attain the required circulator specifications:

- The center frequency is set by the ferrite resonance dimensions.

- The ferrite biasing magnet establishes the non-reciprocal phase shift for isolation.

- Impedance matching networks maximize power transfer and minimize VSWR.

- The port configuration determines magnetic field rotation sense for circulation.

- Dielectric loading around ferrites control impedance level for matching.

Electromagnetic simulations model field interactions to optimize the geometry. Parametric sweeps coupled with experimental measurements fine-tune the prototype design.

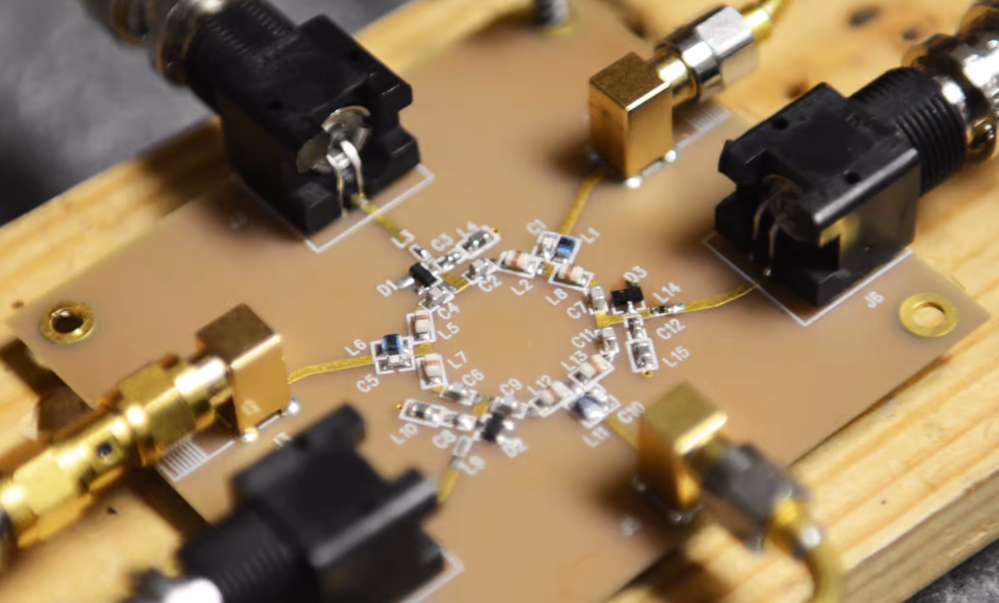

Prototyping and Testing

Fabricating prototypes is key to proving the circulator design:

- The ferrite and dielectric materials must be sourced/synthesized. Ferrites may require custom composition or pre-magnetization.

- Materials are precision machined or molded to achieve target dimensions.

- Components are assembled with mechanical fixes and electrical connections.

- Magnets are integrated to provide proper ferrite biasing.

- RF measurements validate the critical specifications like frequency response, insertion loss, isolation, and power handling.

- Environmental testing establishes thermal and vibration limits.

- Design adjustments are made based on empirical results.

Through iterative prototyping, modeling and testing, the circulator performance is optimized to productize the design.

Conclusion

Key points are:

- RF circulators employ gyromagnetic effects to break reciprocity and enable non-reciprocal microwave signal routing.

- Key specifications like center frequency, bandwidth, loss, isolation, power handling and VSWR guide the design process.

- Material selection, electromagnetic simulation, prototyping and measurements are used to refine and optimize the design to meet requirements.

- Different circulator configurations suit various frequency bands, power levels and connectivity needs.

Successful completion of the design process results in a custom RF circulator tailored to meet the operating specifications of the target application.

Frequently Asked Questions

Q1: What are some typical applications of RF circulators?

Typical uses include separating transmit and receive signals in radar and communications systems, providing isolation between amplifier stages, and creating duplexers for simultaneous transmit and receive operation using a single antenna.

Q2: What determines the operating bandwidth of a circulator?

The ferrite material gyromagnetic properties and the strength of the biasing magnet primarily control the bandwidth over which circulation occurs. Impedance matching networks also play a role. Larger magnetization supports wider bandwidths.

Q3: What limits the maximum power handling in circulators?

At high input power levels, the ferrite material begins to saturate causing the gyromagnetic behavior and non-reciprocity to diminish. Selecting ferrites with higher saturation magnetization extends the maximum RF power handling.

Q4: How are stripline circulators constructed?

Stripline circulators feature a ferrite disk sandwiched between dielectric substrates with copper traces forming the transmission lines. Vias interconnect top and bottom ground planes surrounding the striplines. Compact size allows microwave IC integration.

Q5: What are some alternatives to ferrite circulators?

Faraday rotation in semiconductors can also produce circulation, but lacks ferrite performance. MEMS and electronic approaches using transistors/diodes to actively switch ports are used at lower frequencies. But ferrites remain dominant for passive microwave circulators.

Leave a Reply