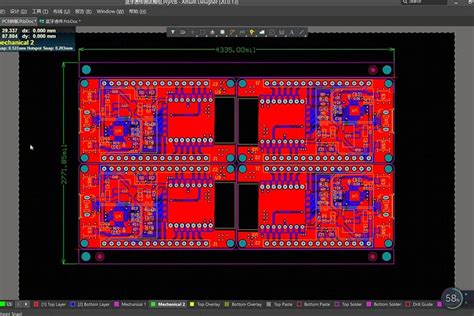

What is PCB Panelization?

PCB panelization is the process of grouping multiple printed circuit board (PCB) designs onto a single panel for manufacturing. This technique is commonly used to reduce production costs, increase efficiency, and streamline the assembly process. By placing multiple PCBs on a single panel, manufacturers can optimize material usage, minimize handling, and speed up the fabrication and assembly stages.

Benefits of PCB Panelization

- Cost Reduction

- Maximizes material utilization

- Reduces setup time and costs

-

Lowers overall manufacturing expenses

-

Improved Efficiency

- Enables batch processing

- Minimizes handling and reduces the risk of damage

-

Speeds up fabrication and assembly processes

-

Consistent Quality

- Ensures uniform production conditions for all PCBs on the panel

- Minimizes variations in manufacturing processes

- Enhances overall product quality and reliability

PCB Panelization Techniques

There are several techniques used for PCB panelization, each with its own advantages and considerations. The choice of panelization method depends on factors such as the PCB design, manufacturing requirements, and assembly processes.

Tab Routing

Tab routing is a popular panelization technique that involves connecting individual PCBs with thin tabs. These tabs hold the boards together during the fabrication and assembly stages. After the assembly is complete, the tabs are broken or cut to separate the individual PCBs.

Advantages of Tab Routing

- Simple and cost-effective

- Suitable for most PCB designs

- Enables easy separation of individual boards

Considerations for Tab Routing

- Tab design and placement are critical to avoid damage during separation

- May require additional design modifications for proper tab integration

V-Scoring

V-scoring is another panelization method that uses V-shaped grooves to define the boundaries between individual PCBs. These grooves are partially cut through the panel, allowing for easy separation of the boards after assembly.

Advantages of V-Scoring

- Provides clean and smooth edges after separation

- Reduces stress on the PCBs during the separation process

- Suitable for designs with irregular shapes or contours

Considerations for V-Scoring

- Requires precise control of the V-score depth to avoid damaging the PCBs

- May not be suitable for thick or multi-layer PCBs

Perforated Tabs

Perforated tabs combine the concepts of tab routing and V-scoring. Small holes are drilled along the tab lines, creating perforations that allow for easy separation of the individual PCBs.

Advantages of Perforated Tabs

- Provides a balance between ease of separation and board stability

- Reduces the risk of damage during the separation process

- Suitable for a wide range of PCB designs

Considerations for Perforated Tabs

- Requires precise hole placement and drilling to ensure clean separation

- May not be ideal for very small or dense PCB designs

Designing for PCB Panelization

To ensure successful PCB panelization, it is essential to consider panelization requirements during the design phase. Here are some key factors to keep in mind:

- Panel Size and Layout

- Determine the optimal panel size based on the manufacturing capabilities and cost considerations

- Arrange the individual PCBs on the panel to maximize material utilization and minimize waste

-

Consider the spacing between boards and the placement of tooling holes and fiducials

-

Tab or V-Score Design

- Incorporate tabs or V-scores into the PCB design to facilitate panelization

- Ensure that the tab or V-score dimensions are compatible with the manufacturing processes

-

Consider the strength and stability of the tabs or V-scores during handling and assembly

-

Component Clearance

- Provide sufficient clearance between components and the edges of the individual PCBs

- Ensure that components do not interfere with the panelization features, such as tabs or V-scores

-

Consider the assembly processes and any potential limitations imposed by the panelization method

-

Fiducial Marks and Tooling Holes

- Include fiducial marks and tooling holes in the panel design to aid in alignment and registration during manufacturing

- Follow the manufacturer’s guidelines for the placement and size of fiducial marks and tooling holes

- Ensure that these features do not interfere with the individual PCB designs or panelization methods

Screaming Circuits’ PCB Panelization Services

Screaming Circuits, a leading provider of PCB manufacturing and assembly services, offers comprehensive PCB panelization solutions to meet the diverse needs of its customers. With state-of-the-art equipment, experienced engineers, and a commitment to quality, Screaming Circuits ensures that your panelized PCBs are produced to the highest standards.

Panelization Capabilities

Screaming Circuits offers a wide range of PCB panelization capabilities, including:

- Tab routing

- V-scoring

- Perforated tabs

- Custom panelization solutions

Their team of experts works closely with customers to determine the most suitable panelization method based on the specific requirements of each project. Whether you have a simple design or a complex, high-density PCB, Screaming Circuits has the expertise and resources to deliver reliable and cost-effective panelization solutions.

Design Support and Consultation

Screaming Circuits provides comprehensive design support and consultation services to help customers optimize their PCB designs for panelization. Their experienced engineers review your design files, offer recommendations, and assist in making any necessary modifications to ensure successful panelization.

By working with Screaming Circuits from the early stages of your project, you can leverage their expertise to streamline the panelization process, reduce costs, and minimize potential issues during manufacturing and assembly.

Quick-Turn Prototyping and Production

Screaming Circuits understands the importance of timely delivery in today’s fast-paced electronics industry. They offer quick-turn prototyping and production services for panelized PCBs, enabling you to get your products to market faster.

With their advanced manufacturing capabilities and efficient processes, Screaming Circuits can deliver high-quality panelized PCBs in as little as 24 hours for prototypes and provide rapid production turnaround times to meet your schedule requirements.

Frequently Asked Questions (FAQ)

- What is the minimum order quantity for panelized PCBs at Screaming Circuits?

-

Screaming Circuits offers low minimum order quantities for panelized PCBs, starting at just one piece. This allows customers to prototype and validate their designs before committing to larger production runs.

-

Can Screaming Circuits accommodate custom panelization requirements?

-

Yes, Screaming Circuits has the expertise and flexibility to accommodate custom panelization requirements. Their team works closely with customers to understand their specific needs and develops tailored solutions to meet those requirements.

-

What file formats does Screaming Circuits accept for PCB panelization?

-

Screaming Circuits accepts a wide range of PCB design file formats, including Gerber, ODB++, and IPC-2581. They also support various CAD software packages, such as Altium Designer, Eagle, and KiCad.

-

How does Screaming Circuits ensure the quality of panelized PCBs?

-

Screaming Circuits employs strict quality control measures throughout the manufacturing process. They use advanced equipment, follow industry best practices, and conduct thorough inspections to ensure that panelized PCBs meet the highest quality standards.

-

What is the typical lead time for panelized PCB production at Screaming Circuits?

- Lead times for panelized PCB production at Screaming Circuits vary depending on the complexity of the design and the specific requirements of the project. However, they offer quick-turn prototyping services with lead times as short as 24 hours, and strive to provide fast turnaround times for production orders.

Conclusion

PCB panelization is a critical aspect of PCB manufacturing that offers significant benefits in terms of cost reduction, efficiency, and quality. By understanding the different panelization techniques, designing with panelization in mind, and partnering with a reliable manufacturer like Screaming Circuits, you can ensure the success of your PCB projects.

Screaming Circuits’ comprehensive PCB panelization services, combined with their expertise, advanced capabilities, and commitment to customer satisfaction, make them an ideal choice for all your panelization needs. Whether you are a startups, small business, or a large enterprise, Screaming Circuits has the solutions and support to help you achieve your PCB manufacturing goals.

| Panelization Technique | Advantages | Considerations |

|---|---|---|

| Tab Routing | – Simple and cost-effective – Suitable for most PCB designs – Enables easy separation of individual boards |

– Tab design and placement are critical to avoid damage during separation – May require additional design modifications for proper tab integration |

| V-Scoring | – Provides clean and smooth edges after separation – Reduces stress on the PCBs during the separation process – Suitable for designs with irregular shapes or contours |

– Requires precise control of the V-score depth to avoid damaging the PCBs – May not be suitable for thick or multi-layer PCBs |

| Perforated Tabs | – Provides a balance between ease of separation and board stability – Reduces the risk of damage during the separation process – Suitable for a wide range of PCB designs |

– Requires precise hole placement and drilling to ensure clean separation – May not be ideal for very small or dense PCB designs |

Table 1: Comparison of PCB Panelization Techniques

By leveraging the benefits of PCB panelization and partnering with a trusted manufacturer like Screaming Circuits, you can streamline your PCB manufacturing process, reduce costs, and deliver high-quality products to your customers. Embrace the power of panelization and take your PCB projects to the next level with Screaming Circuits.

Leave a Reply