What is PCB Prepreg?

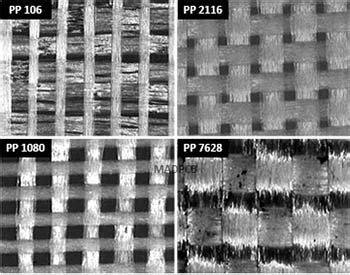

PCB prepreg, short for pre-impregnated, is a key material used in the manufacturing of multilayer printed circuit boards (PCBs). It consists of a reinforcement fabric, such as fiberglass, that is pre-impregnated with a partially cured thermosetting resin, usually epoxy. The prepreg is placed between the inner layers of a multilayer PCB and acts as an insulating and bonding material when the board is subjected to heat and pressure during the lamination process.

Composition of PCB Prepreg

PCB prepreg typically consists of two main components:

-

Reinforcement Fabric: The most common reinforcement fabric used in PCB prepreg is fiberglass, specifically E-glass (electrical grade glass). Other materials, such as S-glass (high strength glass), quartz, or aramid fibers, may be used for specific applications that require higher performance or special properties.

-

Resin System: The resin system in PCB prepreg is usually an epoxy-based thermoset polymer. The resin is partially cured (B-stage) to allow for easy handling and storage. During the lamination process, the resin fully cures, bonding the layers together and providing insulation between the conductive layers.

Key Performance Indicators for PCB Prepreg

To ensure the quality and reliability of multilayer PCBs, several key performance indicators (KPIs) are used to evaluate PCB prepreg materials. These KPIs help PCB manufacturers select the appropriate prepreg for their specific applications and ensure consistent performance throughout the manufacturing process.

1. Glass Transition Temperature (Tg)

The glass transition temperature (Tg) is the temperature at which the prepreg resin transitions from a rigid, glassy state to a softer, rubbery state. A higher Tg indicates better thermal stability and resistance to heat-induced deformation. The Tg of PCB prepreg is typically measured using differential scanning calorimetry (DSC) or dynamic mechanical analysis (DMA).

| Resin System | Typical Tg Range (°C) |

|---|---|

| Standard FR-4 Epoxy | 130 – 140 |

| High Tg FR-4 Epoxy | 170 – 180 |

| Polyimide | 250 – 300 |

| Cyanate Ester | 250 – 290 |

2. Dielectric Constant (Dk) and Dissipation Factor (Df)

The dielectric constant (Dk) and dissipation factor (Df) are critical properties that affect the electrical performance of a PCB. A lower Dk value indicates better signal integrity and faster signal propagation, while a lower Df value indicates lower signal loss and less heat generation.

| Resin System | Typical Dk @ 1 GHz | Typical Df @ 1 GHz |

|---|---|---|

| Standard FR-4 Epoxy | 4.2 – 4.5 | 0.02 – 0.03 |

| Low Dk/Df FR-4 Epoxy | 3.8 – 4.0 | 0.01 – 0.015 |

| Polyimide | 3.5 – 3.8 | 0.01 – 0.02 |

| Cyanate Ester | 3.2 – 3.5 | 0.007 – 0.01 |

3. Coefficient of Thermal Expansion (CTE)

The coefficient of thermal expansion (CTE) measures the rate at which the prepreg expands or contracts with changes in temperature. A lower CTE value indicates better dimensional stability and less stress on the copper traces and vias during thermal cycling. The CTE is typically measured in the Z-axis (through-thickness) direction, as this is the most critical for multilayer PCBs.

| Reinforcement Material | Typical Z-axis CTE (ppm/°C) |

|---|---|

| E-glass | 50 – 70 |

| S-glass | 40 – 60 |

| Quartz | 20 – 30 |

| Aramid | 10 – 20 |

4. Moisture Absorption

Moisture absorption refers to the amount of water that the prepreg can absorb from the environment. High moisture absorption can lead to delamination, warping, and other reliability issues during the manufacturing process or in the field. The moisture absorption of PCB prepreg is typically measured according to IPC-TM-650 Method 2.6.2.1.

| Resin System | Typical Moisture Absorption (%) |

|---|---|

| Standard FR-4 Epoxy | 0.1 – 0.3 |

| High Tg FR-4 Epoxy | 0.1 – 0.2 |

| Polyimide | 0.2 – 0.4 |

| Cyanate Ester | 0.1 – 0.3 |

5. Peel Strength

Peel strength is a measure of the bond strength between the prepreg and the copper foil or the inner layers of the PCB. A higher peel strength indicates better adhesion and resistance to delamination. Peel strength is typically measured using the IPC-TM-650 Method 2.4.8.

| Resin System | Typical Peel Strength (N/mm) |

|---|---|

| Standard FR-4 Epoxy | 1.0 – 1.5 |

| High Tg FR-4 Epoxy | 1.2 – 1.8 |

| Polyimide | 1.5 – 2.0 |

| Cyanate Ester | 1.8 – 2.5 |

Selecting the Right PCB Prepreg

When selecting a PCB prepreg for a specific application, consider the following factors:

-

Electrical Requirements: Choose a prepreg with the appropriate Dk and Df values to meet the signal integrity and loss requirements of your design.

-

Thermal Requirements: Consider the operating temperature range and thermal cycling requirements of your application, and select a prepreg with a suitable Tg and CTE.

-

Mechanical Requirements: Evaluate the physical stresses your PCB will be subjected to and choose a prepreg with adequate peel strength and moisture resistance.

-

Manufacturing Process: Ensure that the selected prepreg is compatible with your manufacturing process, including lamination temperature, pressure, and cycle time.

-

Cost and Availability: Consider the cost and availability of the prepreg material, as well as any minimum order quantities or lead times that may impact your project.

FAQ

1. What is the difference between prepreg and core material in a multilayer PCB?

Prepreg is the uncured, partially polymerized resin-impregnated reinforcement material used to bond the layers of a multilayer PCB together during the lamination process. Core material, on the other hand, is a fully cured, rigid substrate with copper foil bonded to one or both sides, which forms the inner layers of the PCB.

2. Can I use different prepreg materials within the same multilayer PCB?

Yes, it is possible to use different prepreg materials within the same multilayer PCB, depending on the specific requirements of your design. For example, you may use a low Dk/Df prepreg for high-speed signal layers and a standard FR-4 prepreg for power and ground layers. However, ensure that the selected prepregs are compatible with each other and with your manufacturing process.

3. How does the resin content of prepreg affect PCB performance?

The resin content of prepreg affects several aspects of PCB performance, including:

- Dielectric constant and dissipation factor: Higher resin content generally results in a higher Dk and Df.

- Thermal expansion: Higher resin content can lead to a higher CTE, which may impact the dimensional stability of the PCB.

- Adhesion strength: The resin content influences the bond strength between the prepreg and the copper foil or inner layers.

Balancing the resin content is essential to achieve the desired electrical, thermal, and mechanical properties for your specific application.

4. What is the shelf life of PCB prepreg, and how should it be stored?

The shelf life of PCB prepreg depends on the specific resin system and storage conditions, but it typically ranges from 3 to 12 months when stored at room temperature (20-25°C) and low humidity (50-60% RH). To extend the shelf life and maintain the quality of the prepreg, store it in a sealed container or bag in a cool, dry place, away from direct sunlight and sources of heat or moisture.

5. Can I use prepreg with different reinforcement materials in the same multilayer PCB?

Yes, it is possible to use prepregs with different reinforcement materials in the same multilayer PCB, depending on the specific requirements of your design. For example, you may use a quartz or aramid prepreg for layers that require low CTE and high dimensional stability, and an E-glass prepreg for layers that prioritize cost-effectiveness. However, ensure that the selected reinforcement materials are compatible with each other and with your manufacturing process, and consider any potential differences in thermal expansion or mechanical properties that may affect the reliability of the PCB.

Conclusion

PCB prepreg is a critical material in the manufacturing of multilayer PCBs, providing insulation, bonding, and structural support between the conductive layers. Understanding the key performance indicators of PCB prepreg, such as glass transition temperature, dielectric constant, dissipation factor, coefficient of thermal expansion, moisture absorption, and peel strength, is essential for selecting the appropriate material for your specific application.

By carefully considering the electrical, thermal, mechanical, and manufacturing requirements of your project, and working closely with your PCB fabricator and material suppliers, you can ensure that your multilayer PCB design achieves the desired performance, reliability, and cost targets.

Leave a Reply