Introduction to Voltage Regulator PCB

A voltage regulator is an essential component in electronic circuits that ensures a stable and consistent voltage supply to various components. In generating sets, automatic voltage regulators (AVRs) play a crucial role in maintaining the output voltage within the desired range, even under varying load conditions. The voltage regulator PCB (Printed Circuit Board) is the heart of the AVR system, housing all the necessary components and circuitry to control and regulate the voltage effectively.

In this article, we will delve into the process of generating and setting up the automatic voltage regulator PCB circuit for generating sets. We will cover the basic principles of voltage regulation, the components involved, and the step-by-step procedure for designing and manufacturing the PCB.

Understanding the Basics of Voltage Regulation

Voltage regulation is the process of maintaining a constant voltage level in an electrical system, regardless of changes in load or input voltage. The primary goal of a voltage regulator is to ensure that the output voltage remains within a specified range, typically ±5% or ±10% of the nominal value.

There are two main types of voltage regulators:

- Linear voltage regulators

- Switching voltage regulators

Linear voltage regulators work by continuously adjusting the resistance in series with the load to maintain a constant output voltage. They are simple in design but have lower efficiency compared to switching regulators.

Switching voltage regulators, on the other hand, use a high-frequency switching technique to regulate the voltage. They are more efficient than linear regulators but have a more complex design and may introduce noise into the system.

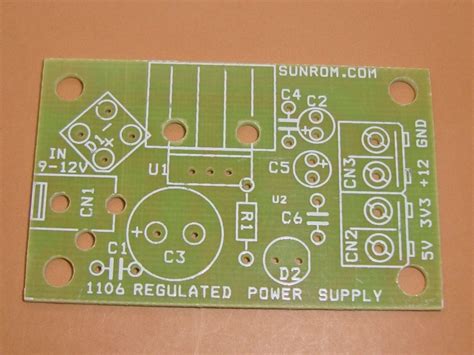

Components of an Automatic Voltage Regulator PCB

The automatic voltage regulator PCB consists of several key components that work together to ensure stable and precise voltage regulation. These components include:

- Voltage reference: Provides a stable reference voltage for comparison with the output voltage.

- Error amplifier: Compares the output voltage with the reference voltage and generates an error signal proportional to the difference.

- Pulse-width modulation (PWM) controller: Generates a PWM signal based on the error signal to control the switching of power transistors.

- Power transistors: Act as switches to control the flow of current through the transformer windings.

- Rectifier and filter: Convert the AC output from the transformer into a smooth DC voltage.

- Protection circuits: Safeguard the AVR against over-voltage, over-current, and short-circuit conditions.

Table 1: Key Components of an AVR PCB

| Component | Function |

|———–|———-|

| Voltage reference | Provides a stable reference voltage |

| Error amplifier | Compares output voltage with reference |

| PWM controller | Generates PWM signal for switching |

| Power transistors | Control current flow in transformer |

| Rectifier and filter | Convert AC to smooth DC voltage |

| Protection circuits | Safeguard against faults |

Designing the Automatic Voltage Regulator PCB

Designing an automatic voltage regulator PCB involves several steps, including schematic design, component selection, and PCB layout. Let’s take a closer look at each of these steps.

Schematic Design

The first step in designing an AVR PCB is to create a schematic diagram that represents the electrical connections between the various components. The schematic should include all the necessary components, such as the voltage reference, error amplifier, PWM controller, power transistors, rectifier, and filter.

When designing the schematic, it is essential to consider factors such as the required voltage and current ratings, the desired regulation accuracy, and the protection features needed.

Component Selection

Once the schematic is complete, the next step is to select the appropriate components for the AVR PCB. The selection process should take into account the electrical specifications, thermal characteristics, and cost of each component.

Some key considerations when selecting components include:

- Voltage and current ratings: Ensure that the components can handle the expected voltage and current levels in the circuit.

- Accuracy and stability: Choose components with high accuracy and stability to ensure precise voltage regulation.

- Thermal characteristics: Select components that can dissipate heat effectively to prevent overheating and ensure long-term reliability.

- Cost: Balance the cost of components with the required performance and reliability.

PCB Layout

After selecting the components, the next step is to create the PCB layout. The layout should be designed to minimize noise, ensure proper grounding, and provide adequate cooling for the components.

Some best practices for PCB layout include:

- Separating analog and digital circuits to minimize noise interference.

- Using ground planes to provide a low-impedance return path for currents.

- Placing power components, such as transistors and rectifiers, away from sensitive analog circuits.

- Providing sufficient copper area for heat dissipation, especially for power components.

- Following the manufacturer’s recommended footprints and layouts for specific components.

Manufacturing the Automatic Voltage Regulator PCB

Once the PCB layout is complete, the next step is to manufacture the PCB. This process typically involves the following steps:

- Generating Gerber files: Export the PCB layout as Gerber files, which are industry-standard files used for PCB fabrication.

- Choosing a PCB manufacturer: Select a reputable PCB manufacturer with experience in producing high-quality PCBs for power electronics applications.

- Specifying the PCB requirements: Provide the manufacturer with the necessary specifications, such as the number of layers, material type, copper thickness, and surface finish.

- Ordering the PCB: Place an order for the required quantity of PCBs, considering factors such as lead time and cost.

Table 2: Typical PCB Specifications for AVR Circuit

| Specification | Value |

|—————|——-|

| Number of layers | 2 or 4 |

| Material | FR-4 |

| Copper thickness | 1 oz or 2 oz |

| Minimum trace width | 0.2 mm |

| Minimum via diameter | 0.4 mm |

Assembling and Testing the Automatic Voltage Regulator PCB

After receiving the manufactured PCBs, the next step is to assemble the components onto the board and test the completed AVR circuit. The assembly process involves the following steps:

- Solder paste application: Apply solder paste to the component pads using a stencil or syringe.

- Component placement: Place the components onto the PCB, ensuring correct orientation and alignment.

- Reflow soldering: Place the PCB in a reflow oven to melt the solder paste and create a strong bond between the components and the PCB.

- Inspection: Visually inspect the assembled PCB for any defects, such as bridging, poor solder joints, or misaligned components.

After assembly, the AVR PCB must be tested to ensure proper functionality and performance. Some key tests include:

- Power-on test: Apply the appropriate input voltage and verify that the output voltage is within the specified range.

- Load test: Apply various load conditions to the AVR and ensure that the output voltage remains stable and within the specified range.

- Protection test: Simulate fault conditions, such as over-voltage or short-circuit, to verify that the protection circuits are functioning correctly.

Frequently Asked Questions (FAQ)

-

Q: What is the purpose of an automatic voltage regulator in a generating set?

A: An automatic voltage regulator (AVR) in a generating set maintains a stable output voltage within a specified range, even under varying load conditions. This ensures that the connected equipment receives a consistent and reliable power supply. -

Q: What are the main types of voltage regulators used in AVR PCBs?

A: The two main types of voltage regulators used in AVR PCBs are linear voltage regulators and switching voltage regulators. Linear regulators are simple but less efficient, while switching regulators are more efficient but have a more complex design. -

Q: What are the key components in an automatic voltage regulator PCB?

A: The key components in an AVR PCB include a voltage reference, error amplifier, PWM controller, power transistors, rectifier and filter, and protection circuits. Each component plays a crucial role in ensuring stable and precise voltage regulation. -

Q: What factors should be considered when selecting components for an AVR PCB?

A: When selecting components for an AVR PCB, factors such as voltage and current ratings, accuracy and stability, thermal characteristics, and cost should be considered. It is essential to choose components that can handle the expected electrical and thermal stresses while providing the required performance and reliability. -

Q: What are some best practices for designing the PCB layout for an AVR circuit?

A: Some best practices for designing the PCB layout for an AVR circuit include separating analog and digital circuits, using ground planes, placing power components away from sensitive analog circuits, providing sufficient copper area for heat dissipation, and following the manufacturer’s recommended footprints and layouts for specific components.

Conclusion

Generating and setting up the automatic voltage regulator PCB circuit is a critical aspect of ensuring stable and reliable power supply in generating sets. By understanding the basic principles of voltage regulation, selecting the appropriate components, and following best practices for PCB design and manufacturing, engineers can create robust and efficient AVR systems.

Throughout this article, we have covered the key components of an AVR PCB, the steps involved in designing and manufacturing the PCB, and the importance of proper assembly and testing. By adhering to these guidelines and continuously improving the design based on performance feedback, manufacturers can produce high-quality AVR PCBs that meet the demanding requirements of modern generating sets.

As technology advances and the demand for stable and efficient power supply grows, the role of automatic voltage regulators and their associated PCBs will continue to be crucial in the power generation industry.

Leave a Reply