Overview of CuClad 6250 Bonding Film

CuClad 6250 is a ceramic-filled fluoropolymer composite designed for bonding and sealing applications at high temperatures. It combines the temperature resistance of polyimide films with the high bond strength of epoxy films.

Some key features of CuClad 6250 include:

- Withstands continuous use temperatures up to 400°F (204°C)

- High lap shear strength up to 2500 psi

- Low outgassing properties

- Dimensionally stable

- Easy to fabricate using standard heat and pressure bonding techniques

CuClad 6250 is supplied in film form and can be die-cut into custom shapes and sizes. It bonds well to metals, composites, and high temperature plastics.

Applications of CuClad 6250

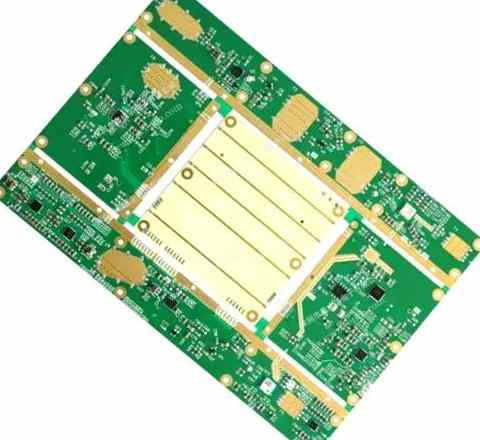

CuClad 6250 is ideal for bonding and sealing in high temperature electronics and electrical components. Some example applications include:

- Bonding heat sinks and baseplates in power electronics

- Sealing hybrid microelectronics packages

- Bonding thermoelectric modules

- Bonding ceramic substrates

- Sealing aerospace and aviation components

The high strength bonds and temperature resistance make it suitable for applications where thermal cycling, vibration, and mechanical shock are present.

Bonding Process for CuClad 6250

CuClad 6250 can be bonded using standard heat and pressure bonding techniques:<table> <tr><th>Bonding Parameter</th><th>Value</th></tr> <tr><td>Bonding Temperature</td><td>375-400°F (190-204°C)</td></tr> <tr><td>Bond Pressure </td><td>300-500 psi</td></tr> <tr><td>Time at Temperature</td><td>1-2 hours</td></tr> </table>

The surfaces to be bonded must be clean and free of contaminants. Heating can be done in a press, autoclave, or oven. Dwell time at temperature depends on the materials being bonded.

FAQ

What are some alternatives to CuClad 6250 for high temperature bonding?

Some alternatives include polyimide films, ceramic-filled PTFE films, and high temperature epoxy films. Each has trade-offs in max temperature, bond strength, outgassing, and ease of use.

Can CuClad 6250 be die-cut to custom shapes and sizes?

Yes, CuClad 6250 is readily die-cut using rotary or steel-rule die cutting tools. Tight tolerances down to +/- 0.005″ are possible.

Does CuClad 6250 require an adhesive resin?

No, CuClad 6250 bonds directly to substrates under heat and pressure without need for an additional adhesive resin.

What type of surface preparation is required?

Surfaces should be clean and free of oil, grease, oxides, and particulates. Light abrasion can help improve bond strength.

What are some key challenges when bonding with CuClad 6250?

Challenges include getting uniform heat and pressure across the bond line, preventing flash when die-cutting, and minimizing trapped gases during cure. Proper fixturing helps overcome these.

Leave a Reply