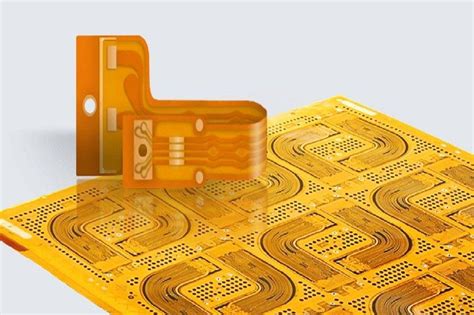

Advantages of Flex PCB

Flex PCBs offer several benefits compared to rigid PCBs:

- Flexibility and bendability

- Lightweight and thin profile

- Increased reliability due to reduced interconnections

- Improved signal integrity

- Design freedom and space savings

- Resistance to shock and vibration

- Suitability for dynamic and high-stress applications

These advantages make flex PCBs a preferred choice for many electronic applications, especially those requiring compact, lightweight, and reliable interconnect solutions.

Applications of Flex PCB

Consumer Electronics

Flex PCBs are extensively used in consumer electronics due to their ability to enable slim, lightweight, and compact designs. Some common applications include:

- Smartphones and tablets

- Wearable devices (smartwatches, fitness trackers)

- Laptops and notebooks

- Digital cameras and camcorders

- Gaming consoles and controllers

- Smart home devices (thermostats, security systems)

Flex PCBs allow designers to create folding or rolling displays, hinged designs, and curved surfaces in consumer electronics, enhancing both functionality and aesthetics.

Medical Devices

The medical industry relies on flex PCBs for various applications that require reliability, biocompatibility, and the ability to fit into compact spaces. Examples include:

- Implantable devices (pacemakers, neurostimulators)

- Wearable monitoring systems

- Surgical instruments and endoscopes

- Hearing aids

- Portable medical equipment (glucose meters, blood pressure monitors)

Flex PCBs enable the development of miniaturized, lightweight, and ergonomic medical devices that improve patient comfort and ease of use for healthcare professionals.

Automotive Electronics

The automotive industry increasingly adopts flex PCBs to enable advanced features and functionalities in vehicles. Some applications include:

- Infotainment systems and displays

- Instrument clusters and dashboard electronics

- Advanced driver assistance systems (ADAS)

- Lighting systems (LED headlights, interior lighting)

- Sensors (temperature, pressure, accelerometer)

- Electric vehicle battery management systems

Flex PCBs help automotive designers create compact, lightweight, and reliable electronic systems that can withstand the harsh environments and vibrations experienced in vehicles.

Aerospace and Defense

Flex PCBs are essential for aerospace and defense applications, where reliability, weight reduction, and space savings are critical. Applications include:

- Avionics systems (flight control, navigation, communication)

- Satellite and spacecraft electronics

- Radar and surveillance systems

- Military wearables and portable devices

- Unmanned aerial vehicles (UAVs) and drones

Flex PCBs enable the development of high-density, lightweight, and robust electronic systems that can operate in extreme conditions, such as high altitudes, temperature fluctuations, and intense vibrations.

Industrial Electronics

Industrial applications often require rugged and reliable electronic systems that can withstand harsh environments. Flex PCBs are used in various industrial applications, such as:

- Factory automation and robotics

- Process control systems

- Power electronics and motor drives

- Sensors and data acquisition systems

- Portable test and measurement equipment

Flex PCBs offer the necessary durability, flexibility, and connectivity to create compact and reliable industrial electronic systems that can operate in challenging conditions.

Telecommunications

The telecommunications industry relies on flex PCBs to enable high-speed data transmission, signal integrity, and compact designs. Applications include:

- Smartphones and mobile devices

- 5G infrastructure and base stations

- Fiber optic networks and transceivers

- Routers and switches

- Antennas and RF modules

Flex PCBs help telecommunication equipment manufacturers create high-density, high-speed interconnects that can support the increasing demand for data transmission and connectivity.

Flex PCB Design Considerations

When designing flex PCBs for various applications, engineers must consider several factors to ensure optimal performance and reliability:

- Material selection (polyimide, adhesives, conductors)

- Bend radius and flexibility requirements

- Signal integrity and impedance control

- Thermal management and heat dissipation

- Manufacturing processes (etching, lamination, coverlay)

- Assembly and interconnection methods (ZIF connectors, soldering)

- Testing and inspection procedures

By carefully addressing these design considerations, engineers can create flex PCBs that meet the specific requirements of each application and ensure reliable performance over the product’s lifecycle.

Future Trends and Developments

As technology continues to advance, the demand for flex PCBs is expected to grow across various industries. Some future trends and developments in flex PCB applications include:

- Increased adoption in IoT and smart devices

- Advancements in materials and manufacturing processes

- Integration of embedded components and sensors

- Development of stretchable and conformable electronics

- Adoption of 3D printing techniques for rapid prototyping

- Expansion into new application areas (e.g., medical implants, soft robotics)

These trends are expected to drive innovation in flex PCB design and manufacturing, enabling the development of more advanced, compact, and reliable electronic systems across industries.

Frequently Asked Questions (FAQ)

1. What is the difference between flex PCBs and rigid PCBs?

Flex PCBs are made from flexible materials, such as polyimide, which allows them to bend, twist, and fold. In contrast, rigid PCBs are made from a rigid substrate material, such as FR-4, and cannot be bent or flexed. Flex PCBs offer advantages in terms of design freedom, space savings, and reliability in applications that require flexibility or conformity to a specific shape.

2. What are the most common materials used in flex PCBs?

The most common base material for flex PCBs is polyimide, which offers excellent thermal stability, mechanical strength, and electrical insulation properties. Copper is the most common conductor material, while adhesives such as acrylic and epoxy are used to bond the layers together. Other materials, such as polyester and Teflon, may be used for specific applications or requirements.

3. Can flex PCBs be used in high-temperature environments?

Yes, flex PCBs can be designed to withstand high-temperature environments. The choice of materials, such as high-temperature polyimide or Teflon, and the use of appropriate manufacturing processes can enable flex PCBs to operate reliably in elevated temperature conditions. However, the specific temperature range and duration must be considered during the design process to ensure optimal performance.

4. How do flex PCBs improve signal integrity compared to rigid PCBs?

Flex PCBs can improve signal integrity by reducing the number of interconnections required between components. In a rigid PCB assembly, components are often connected using wires or cables, which can introduce signal degradation and noise. Flex PCBs allow for direct connections between components, minimizing signal path length and reducing the potential for signal integrity issues. Additionally, flex PCBs can be designed with controlled impedance and shielding to further enhance signal integrity.

5. Are flex PCBs more expensive than rigid PCBs?

In general, flex PCBs tend to be more expensive than rigid PCBs due to the specialized materials, manufacturing processes, and design considerations involved. However, the total cost of ownership should be considered when comparing the two options. Flex PCBs can offer cost savings in terms of reduced assembly time, improved reliability, and space savings, which can offset the higher initial material and manufacturing costs. The specific cost comparison will depend on the application requirements, production volume, and other factors.

Conclusion

Flex PCBs have emerged as a critical enabler for a wide range of electronic applications across industries, offering numerous advantages over traditional rigid PCBs. From consumer electronics and medical devices to automotive and aerospace systems, flex PCBs provide the necessary flexibility, reliability, and performance to create compact, lightweight, and robust electronic assemblies.

As technology continues to advance and new applications emerge, the demand for flex PCBs is expected to grow, driving innovation in materials, manufacturing processes, and design techniques. By understanding the key advantages, applications, and design considerations of flex PCBs, engineers and product developers can leverage this versatile interconnect solution to create the next generation of electronic devices and systems.

Leave a Reply