Introduction to ABS Schematics

Anti-lock Braking System (ABS) is a critical safety feature in modern vehicles that prevents the wheels from locking up during sudden or hard braking. This system allows the driver to maintain steering control and reduces the stopping distance, especially on slippery roads. Understanding the schematics of an ABS is essential for automotive engineers, technicians, and enthusiasts who want to diagnose, repair, or modify the system.

What is an ABS Schematic?

An ABS schematic is a detailed diagram that represents the various components and their interconnections within the Anti-lock Braking System. It serves as a visual guide to understand the system’s layout, electrical connections, and hydraulic circuits.

Importance of ABS Schematics

ABS schematics are crucial for several reasons:

- Troubleshooting: When an ABS malfunctions, technicians refer to the schematics to identify the faulty component and trace the root cause of the problem.

- Maintenance: Schematics help in understanding the proper maintenance procedures for ABS components, such as bleeding the brake fluid or replacing worn-out parts.

- Modifications: For those who want to upgrade or modify their vehicle’s ABS, schematics provide the necessary information to ensure proper integration of new components.

Components of an ABS

To comprehend ABS schematics, it is essential to understand the key components that make up the system.

Wheel Speed Sensors

Wheel speed sensors are located at each wheel and monitor the rotational speed of the wheels. They send this information to the ABS control module, which determines if any wheel is about to lock up during braking.

| Sensor Location | Sensor Type | Function |

|---|---|---|

| Front Left | Hall Effect | Measures wheel speed |

| Front Right | Hall Effect | Measures wheel speed |

| Rear Left | Hall Effect | Measures wheel speed |

| Rear Right | Hall Effect | Measures wheel speed |

ABS Control Module

The ABS control module, also known as the Electronic Control Unit (ECU), is the brain of the system. It receives input from the wheel speed sensors and determines when to activate the ABS. The control module also performs self-diagnostics and stores trouble codes for later retrieval.

Hydraulic Control Unit

The hydraulic control unit consists of a series of valves that regulate the brake fluid pressure to each wheel. When the ABS is activated, the valves rapidly open and close to modulate the brake fluid pressure, preventing wheel lockup.

| Valve | Function |

|---|---|

| Isolation Valve | Separates the brake fluid circuit from the master cylinder |

| Inlet Valve | Controls the flow of brake fluid into the wheel cylinder |

| Outlet Valve | Controls the flow of brake fluid out of the wheel cylinder |

Pump and Motor

The pump and motor work together to restore the brake fluid pressure that is released by the hydraulic control unit during ABS activation. The motor drives the pump, which quickly pumps the brake fluid back into the system, ensuring that the brakes are ready for the next application.

ABS Schematic Diagrams

Basic ABS Schematic

A basic ABS schematic shows the interconnections between the main components of the system. It includes the wheel speed sensors, ABS control module, hydraulic control unit, pump, and motor.

[Insert basic ABS schematic diagram here]

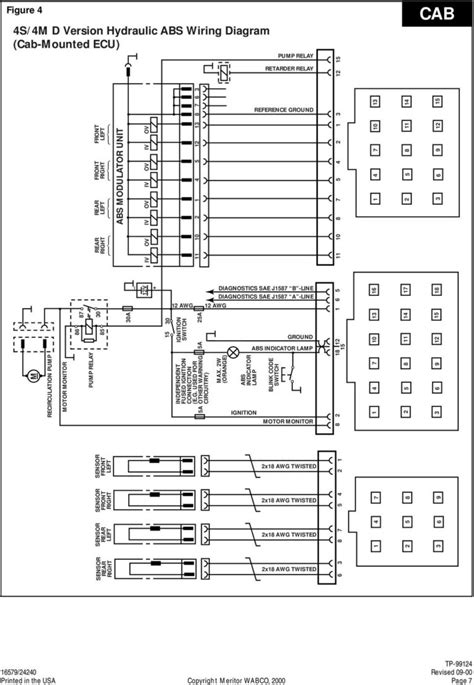

Detailed ABS Schematic

A detailed ABS schematic provides a more in-depth look at the system, including the specific wiring connections, ground points, and fuse locations. This schematic is essential for advanced troubleshooting and modifications.

[Insert detailed ABS schematic diagram here]

Interpreting ABS Schematics

When interpreting ABS schematics, it is essential to follow the flow of information and power through the system.

Tracing the Wheel Speed Sensor Circuit

Start by locating the wheel speed sensors on the schematic. Trace the wiring from each sensor to the ABS control module. Note any connectors, ground points, or fuses along the way.

Understanding the Hydraulic Control Unit

Identify the hydraulic control unit on the schematic and observe the connections to the brake fluid reservoir, master cylinder, and wheel cylinders. Pay attention to the location and function of each valve within the unit.

Analyzing the Pump and Motor Circuit

Trace the wiring from the ABS control module to the pump and motor. Note the power supply, ground connections, and any relays or fuses in the circuit.

Common ABS Problems and Schematic Diagnosis

When an ABS malfunctions, the schematic can help pinpoint the problem area.

Wheel Speed Sensor Faults

If a wheel speed sensor fails, the ABS control module will detect an abnormal signal or no signal at all. Consult the schematic to check for damaged wiring, loose connections, or a faulty sensor.

Control Module Issues

A malfunctioning ABS control module can cause various issues, such as erratic ABS activation or failure to activate at all. Use the schematic to verify proper power supply and ground connections to the module.

Hydraulic Control Unit Problems

Leaks, stuck valves, or contaminated brake fluid can cause problems within the hydraulic control unit. The schematic can help identify the affected components and guide the repair process.

Frequently Asked Questions (FAQ)

- Can I drive my vehicle if the ABS light is on?

-

While it is possible to drive with the ABS light on, it is not recommended. The ABS may not function properly, increasing the risk of wheel lockup during hard braking. It is best to have the system diagnosed and repaired as soon as possible.

-

How often should I have my ABS inspected?

-

It is a good idea to have your ABS inspected during regular brake system maintenance, such as brake pad replacements or fluid changes. Consult your vehicle’s owner’s manual for specific maintenance intervals.

-

Can I replace just one wheel speed sensor, or do I need to replace all of them?

-

If a single wheel speed sensor fails, you can replace just that sensor. However, if the sensors are worn due to age or contamination, it may be wise to replace all of them at the same time to ensure optimal ABS performance.

-

What should I do if my ABS activates unexpectedly?

-

If your ABS activates when braking under normal conditions, it could indicate a problem with the system. Have a professional diagnose the issue using the ABS schematic to determine the cause and appropriate repair.

-

Can I upgrade my vehicle’s ABS?

- While it is possible to upgrade certain components of your vehicle’s ABS, such as installing larger brake rotors or high-performance brake pads, it is essential to ensure compatibility with the existing system. Consult the ABS schematic and a professional before making any modifications.

Conclusion

Understanding ABS schematics is crucial for diagnosing, repairing, and maintaining the Anti-lock Braking System in modern vehicles. By familiarizing yourself with the components, layout, and common problems, you can ensure that your vehicle’s ABS continues to provide optimal safety and performance.

Remember to always consult the specific schematic for your vehicle’s make and model, as there may be variations between different manufacturers and years. With a solid understanding of ABS schematics, you can keep your vehicle’s braking system in top condition and enjoy a safer driving experience.

Leave a Reply