Introduction

Printed circuit boards (PCBs) are vital components in nearly all modern electronics. To create functional and reliable PCBs, designers must carefully select the right materials. One key material choice is the bonding film used to laminate copper foil to dielectric substrates during innerlayer production. Rogers Corporation’s CuClad 6700 is a leading bonding film option for high-frequency and high-performance PCB designs.

In this comprehensive guide, we’ll explore the key characteristics, applications, benefits, and design considerations for Rogers CuClad 6700 bonding film. Whether you’re new to PCB materials selection or an experienced designer, this overview will provide valuable insights on how CuClad 6700 can enable your next project. We’ll also answer common questions to address any knowledge gaps you may have on Rogers’ industry-leading bonding film technology.

What is Rogers CuClad 6700?

Rogers CuClad 6700 is a filled, cyanate ester resin bonding film manufactured by Rogers Corporation for use in multilayer PCB fabrication. The key features of CuClad 6700 include:

- Filled resin system with a high glass transition temperature of 270°C

- Low X-Y thermal expansion for reliable plated through holes (PTHs)

- High bond strength and peel strength for robust multilayer adhesion

- Excellent dimensional stability during lamination

- Halogen-free and lead-free (RoHS compliant)

- Compatible with a wide range of dielectric materials

CuClad 6700 has a unique filler package that provides exceptional thermal, mechanical, and electrical performance compared to traditional FR-4 bonding films. It bonds continuously to copper foil and laminate substrates during the multilayer pressing process. The properties of CuClad 6700 make it well-suited for high-frequency RF/microwave PCBs in applications like 5G, military/aerospace, automotive radar, and test & measurement equipment.

Key Properties and Specifications

Here are some of the key properties and specifications of Rogers CuClad 6700 bonding film:

Physical Properties

- Thickness: 0.002″ (0.05mm) standard

- Specific Gravity: 1.7

- Color: Light brown

- Shelf Life: 6 months at 23°C and 50% RH

Electrical Properties

- Dielectric Constant: 3.2 at 10 GHz

- Loss Tangent: 0.004 at 10 GHz

- Volume Resistivity: >1 x 10<sup>15</sup> ohm-cm

Thermal Properties

- Glass Transition (T<sub>g</sub>): 270°C (DSC)

- Decomposition Temperature: >350°C

- Coefficient of Thermal Expansion (CTE):

- X-Y CTE: 30-40 ppm/°C

- Z-Axis CTE: 140-160 ppm/°C

Mechanical Properties

- Young’s Modulus: 4600 MPa

- Poisson’s Ratio: 0.24

- Shear Modulus: 1800 MPa

- Tensile Strength: >70 MPa

- Elongation at Break: 4%

Bonding Properties

- 180° Peel Strength: >2.5 lb/in

- Lap Shear Strength: >2500 psi

With its advanced filler package and cyanate ester resin chemistry, these properties make CuClad 6700 suitable for boards with 12+ layers, fine lines/spaces (<5 mil width), and 1 oz copper or thinner foil.

Why Use CuClad 6700 Bonding Film?

Rogers CuClad 6700 offers several key advantages that make it the ideal bonding film for many advanced PCB designs:

High Reliability

The unique properties of CuClad 6700 allow it to withstand temperature cycling, humidity exposure, thermal shock, and other reliability testing regimens. The robust mechanical performance ensures excellent adhesion and prevents delamination issues.

Dimensional Stability

With a low, glass-fiber reinforced CTE, CuClad 6700 minimizes dimensional changes during lamination. This allows for fine features and reliable plated through-holes (PTHs), even on large panel sizes.

High Frequency Performance

CuClad 6700’s low dielectric constant and loss tangent enable excellent high frequency performance. It allows PCBs to achieve target impedance values and consistent performance up to microwave frequencies.

Lead-Free Compatibility

As a lead-free material, CuClad 6700 complies with RoHS and other environmental regulations. It’s compatible with lead-free assembly and soldering processes.

Consistent Quality

Rogers Corporation has over 50 years of experience manufacturing high-performance PCB materials. Customers benefit from consistent quality and reliable supply of CuClad 6700 bonding film.

With these advantages, PCB designers can leverage CuClad 6700 to achieve miniaturization, performance, and reliability goals for advanced circuits and multilayer boards.

PCB Design Guidelines

Here are some key PCB design guidelines to follow when using Rogers CuClad 6700:

Laminate Selection

- Choose dielectric materials compatible with 6700’s thermal and mechanical properties. Common substrates include Rogers RO4000, RO3000, RT/duroid 6000, and various FR-4 materials.

- Match CuClad 6700 with proper dielectric thickness. Use thicker cores (0.020″+) for panel support on high layer count boards.

Layer Count

- CuClad 6700 enables 12+ layer PCBs thanks to its excellent bonding and dimensional stability.

- For high layer counts, incorporate thick metal cores or additional reinforcement in panel design.

Registration

- Precision lamination provided by CuClad 6700 allows for registration down to ±0.003″ (±0.076mm).

- Utilize lamination fiducials and precision drilling/routing technology.

Signal Routing

- Route critical signals on inner layers bonded with CuClad 6700 to minimize loss and impedance mismatches.

- Reference planes above and below signal layers should be 1-2x trace thickness at minimum.

Via Structures

- Plated through-hole (PTH) reliability is excellent with CuClad 6700 thanks to precise registration and stable dimensions.

- Follow dielectric material guidelines for minimum annular ring width around PTH barrels.

- Blind and buried vias can provide additional routing channels when needed.

Copper Foil Type

- Use low profile copper (1/2 oz. or thinner) to achieve fine lines and spaces.

- Standard 1 oz. copper foil is also compatible for typical PCB designs.

Adhering to these guidelines will allow you to achieve maximum benefit from Rogers CuClad 6700’s unique properties and performance capabilities.

Application Examples

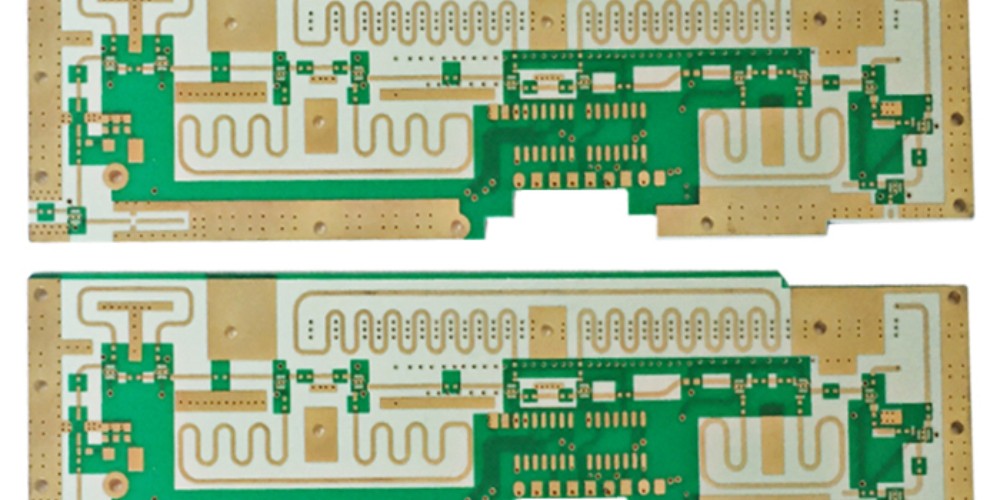

Rogers CuClad 6700 bonding film enables cutting-edge PCBs across a wide variety of end applications:

5G NR Circuits

Next generation 5G networks operate at mmWave frequencies up to 40 GHz. CuClad 6700’s stable electrical performance makes it an ideal choice for 5G PCBs used in base stations, handsets, and infrastructure.

Automotive Radar

High resolution automotive RADAR for ACC, blind spot detection, etc requires precision bonding film. CuClad 6700 provides the exceptional stability needed for 77 GHz antennas and circuits.

Aerospace and Defense

Mission-critical military and aerospace applications demand reliable PCBs that can perform in extreme environments. CuClad 6700’s robust mechanical properties meet their stringent requirements.

High-Speed Digital

With excellent dimensional stability and tight registration tolerances, CuClad 6700 supports fine geometries needed for high-speed digital interfaces like PCIe Gen 5.

Microwave Equipment

Radar, satellite communications, and test equipment incorporate PCBs operating well into microwave frequencies. CuClad 6700 enables excellent high frequency response beyond 10 GHz.

For these and many other applications, designers trust Rogers CuClad 6700 to deliver advanced multilayer PCBs that offer maximum performance and reliability.

Frequently Asked Questions

Here are answers to some common questions about Rogers CuClad 6700:

What types of substrates is it compatible with?

CuClad 6700 bonds continuously with a wide variety of dielectric materials, including FR-4, polyimides, Hydrocarbon Ceramics (Rogers RO3000 series), and PTFE composites (Rogers RO4000 series). It’s also compatible with metal core substrates like aluminum and copper.

Can it be used for sequential lamination?

Yes, CuClad 6700 supports sequential lamination processes. Its high bond strength and dimensional stability enable reliable sub-composite or modular PCB designs.

What is the shelf life of CuClad 6700?

Under proper storage conditions at 23°C and 50% relative humidity, Rogers guarantees a minimum shelf life of 6 months for CuClad 6700 bonding film.

What are the recommended lamination parameters?

Rogers recommends a lamination pressure of 200-300 psi at a temperature of 180-195°C for 60 minutes, with a pressure ramp down after cooling below 100°C.

Is CuClad 6700 compliant with IPC-4101 or IPC-4104?

Yes, CuClad 6700 meets all applicable criteria in IPC-4101E and IPC-4104C standards for base materials. It complies with IPC laminate test methods and acceptance levels.

Conclusion

With its unique properties that enable high layer counts, fine features, and excellent electrical performance, Rogers CuClad 6700 is the ideal bonding film for advanced PCB designs in cutting-edge applications. This article provided an in-depth look at CuClad 6700’s key characteristics, benefits, design guidelines, end uses, and frequently asked questions. By selecting CuClad 6700 for your next multilayer PCB design, you can leverage Rogers’ decades of experience developing specialized high-performance materials that deliver the speed, precision, and reliability that modern electronic circuits demand.

Leave a Reply