What is PCB Panelization?

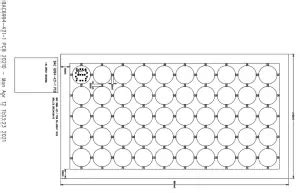

PCB panelization involves arranging multiple individual PCB designs into a larger panel that will be fabricated as a single unit. The panel is then cut or routed to separate the individual boards after manufacturing. Panelization enables batch production of PCBs, which reduces fabrication time and cost compared to manufacturing boards one at a time.

The panelization process requires careful planning to ensure the panel layout is optimized for manufacturing while maintaining the integrity of the individual board designs. Factors such as board spacing, tooling holes, fiducial marks, breakaway tabs, and test coupons must be considered. PCB panelization software automates much of this process and helps ensure optimal panel design.

Benefits of Using Software for PCB Panelization

Using specialized software for PCB panelization provides several key benefits:

- Automation – Panelization software automates the process of arranging and optimizing the panel layout, saving time and reducing the risk of errors compared to manual methods.

- Optimization – Advanced algorithms in panelization software can optimize the panel layout for manufacturing efficiency, material usage, and cost. This includes features like automatic placement of tooling holes, fiducials, and test coupons.

- Design Rule Checking (DRC) – Panelization software can check the panel layout against manufacturing design rules to ensure it meets fabrication requirements. This helps avoid costly mistakes and production delays.

- Customization – Panelization software provides options to customize the panel layout based on specific project requirements, such as board spacing, tab design, and drill sizes.

- Output Generation – Once the panel layout is complete, panelization software can generate output files in industry-standard formats like Gerber and Excellon. These files are used to fabricate the panel.

Key Features to Look for in PCB Panelization Software

When evaluating PCB panelization software, look for the following key features:

- Ease of Use – The software should have an intuitive interface that is easy to navigate and use, even for those new to panelization.

- Automated Panel Layout – Look for software that can automatically arrange and optimize the panel layout based on the individual board designs and manufacturing requirements.

- Design Rule Checking – The software should include DRC capabilities to validate the panel layout against manufacturing constraints and identify any issues.

- Customization Options – The ability to customize the panel layout is important to meet specific project requirements. Look for software with options to adjust board spacing, tab design, fiducials, and other parameters.

- Output Generation – The software should be able to generate industry-standard output files like Gerber and Excellon that can be sent directly to the manufacturer.

- Integration with PCB Design Tools – If you use a specific PCB design tool, look for panelization software that integrates with it directly to streamline your workflow.

- Cost and Licensing – Consider the cost of the software and any recurring licensing fees. Some panelization software is available for free, while others require a one-time or subscription-based license.

PCB Panelization Software Options

There are several PCB panelization software options available, ranging from free open-source tools to commercial solutions. Here are a few popular options:

| Software | Type | Key Features |

|---|---|---|

| gerbv | Free / Open-Source | Gerber viewer, basic panelization |

| PCB Elegance | Free | Panel layout, Gerber output |

| CAM350 | Commercial | Advanced panel layout, DRC, Gerber output |

| Pulsonix | Commercial | Panel layout, DRC, Gerber output |

| Ucamco Panelizer | Commercial | Advanced panel optimization |

These are just a few examples – there are many other PCB panelization software tools available to meet different needs and budgets. It’s important to evaluate your specific requirements and compare features when selecting a panelization solution.

Panelization Considerations and Best Practices

When using software for PCB panelization, keep the following considerations and best practices in mind:

- Manufacturing Requirements – Understand the fabrication capabilities and constraints of your manufacturing partner. This includes minimum board spacing, tab size, drill sizes, and other design rules.

- Material Usage – Consider the size and shape of the panel to optimize material usage and minimize waste. Panelization software can help with this optimization.

- Panel Orientation – Orient the individual boards on the panel to balance copper distribution and minimize warping during fabrication.

- Tooling Holes and Fiducials – Include appropriate tooling holes and fiducial marks on the panel to aid in fabrication and assembly. Panelization software can automatically place these elements.

- Test Coupons – Consider including test coupons on the panel that can be used to verify the quality of the fabrication process.

- Breakaway Tabs – Design breakaway tabs that allow the individual boards to be easily separated from the panel after fabrication. The size and style of tabs can be customized in panelization software.

- Review and Verification – Always carefully review the panelized layout generated by the software to ensure it meets your requirements and manufacturing constraints. Verify the output files before sending them for fabrication.

By following these best practices and leveraging the capabilities of panelization software, you can create optimized panel layouts that streamline the PCB manufacturing process.

Conclusion

PCB panelization is a critical step in the PCB manufacturing process that enables efficient batch production of circuit boards. Using specialized software for panelization automates and optimizes the process of creating panel layouts. Panelization software offers benefits such as automation, optimization, design rule checking, customization, and output generation.

When selecting PCB panelization software, look for key features like ease of use, automated panel layout, DRC capabilities, customization options, and output generation. There are several software options available, ranging from free tools to advanced commercial solutions.

To get the most out of panelization software, consider manufacturing requirements, material usage, panel orientation, tooling holes and fiducials, test coupons, and breakaway tabs. Always review and verify the panelized layout before sending it for fabrication.

By understanding the capabilities and considerations of PCB panelization software, you can streamline your PCB design and manufacturing process for optimal efficiency and cost savings.

Frequently Asked Questions (FAQ)

1. What is the purpose of PCB panelization?

PCB panelization allows multiple individual PCB designs to be fabricated together on a single panel, which is more efficient than manufacturing boards one at a time. Panelization reduces fabrication time and cost.

2. What are the benefits of using software for PCB panelization?

Using software for PCB panelization offers benefits such as automation of the panel layout process, optimization for manufacturing efficiency and cost, design rule checking to verify the layout meets fabrication constraints, customization options to meet specific requirements, and output generation in industry-standard formats.

3. What key features should I look for in PCB panelization software?

When evaluating PCB panelization software, look for key features such as ease of use, automated panel layout capabilities, design rule checking, customization options, output generation in standard formats, integration with your PCB design tools, and cost/licensing considerations.

4. What are some best practices to follow when using PCB panelization software?

Some best practices for PCB panelization include understanding manufacturing requirements and constraints, optimizing material usage, balancing panel orientation, including tooling holes and fiducials, considering test coupons, designing appropriate breakaway tabs, and carefully reviewing and verifying the panelized layout before fabrication.

5. Can I use free or open-source software for PCB panelization?

Yes, there are some free and open-source options available for PCB panelization, such as gerbv and PCB Elegance. These tools may have more limited features compared to commercial solutions but can still be effective for basic panelization needs. It’s important to evaluate your specific requirements and compare features when selecting a panelization solution.

Leave a Reply