The Rogers TMM 3 is a popular loudspeaker system that has been in the market for several years. It is a three-way floor-standing speaker that offers exceptional sound quality and performance. The TMM 3 is designed to deliver a natural and balanced sound that is perfect for music enthusiasts and audiophiles.

One of the standout features of the TMM 3 is its unique driver configuration. It features a 1-inch aluminum dome tweeter, a 5.25-inch midrange driver, and two 8-inch woofers. This driver configuration ensures that the speaker can accurately reproduce a wide range of frequencies, from the highest highs to the lowest lows. Additionally, the TMM 3 is built with high-quality components that are designed to last for years, making it a worthwhile investment for anyone looking for a reliable and high-performing loudspeaker.

Overall, the Rogers TMM 3 is a great choice for anyone looking for a high-quality loudspeaker system that can deliver exceptional sound quality and performance. Its unique driver configuration and high-quality components make it a standout option in its price range, and its natural and balanced sound is sure to impress even the most discerning audiophile.

Overview of Rogers TMM 3

The Rogers TMM 3 is a highly versatile and reliable testing machine used in a wide range of industries for testing the mechanical properties of materials. It is a universal testing machine that can perform a variety of tests such as tensile, compression, flexural, and shear tests. The machine is designed to provide accurate and repeatable results, making it an ideal choice for quality control and research applications.

One of the key features of the Rogers TMM 3 is its high precision load cell, which ensures accurate force measurement. The load cell is designed to provide a wide range of force measurement capabilities, from low loads to high loads. The machine also features a high-resolution displacement transducer that provides accurate displacement measurement.

The Rogers TMM 3 is equipped with a user-friendly software interface that allows for easy test setup and data acquisition. The software provides a variety of test methods and allows for customization of test parameters. The machine also features a large LCD display that provides real-time data during testing.

In addition to its high precision and user-friendly interface, the Rogers TMM 3 is also designed for safety. The machine features a variety of safety mechanisms such as overload protection, emergency stop, and interlock switches.

Overall, the Rogers TMM 3 is a reliable and versatile testing machine that provides accurate and repeatable results. Its high precision load cell, user-friendly software interface, and safety mechanisms make it an ideal choice for a wide range of testing applications.

Key Features of Rogers TMM 3

The Rogers TMM 3 is a high-end test and measurement system designed for use in the telecommunications industry. Here are some of its key features:

1. Multiple Test Capabilities

The Rogers TMM 3 offers a wide range of test capabilities, including impedance, insertion loss, and phase measurements. It is also capable of measuring the dielectric constant and loss tangent of materials, making it an ideal tool for material analysis and characterization.

2. High Accuracy and Precision

The TMM 3 is known for its high accuracy and precision, thanks to its advanced calibration and measurement techniques. It is capable of measuring with a resolution of up to 0.0001, making it an ideal tool for demanding applications that require precise measurements.

3. User-Friendly Interface

The TMM 3 features a user-friendly interface that makes it easy to set up and run tests. The system is controlled using a touch-screen display and comes with intuitive software that guides users through the testing process step-by-step.

4. Wide Frequency Range

The TMM 3 is capable of measuring over a wide frequency range, from 10 MHz to 50 GHz. This makes it an ideal tool for testing a wide range of telecommunications components, including antennas, filters, and amplifiers.

5. Modular Design

The TMM 3 features a modular design that allows users to customize the system to meet their specific testing needs. This means that users can add or remove modules as needed, making the TMM 3 a versatile tool that can be adapted to a wide range of applications.

In summary, the Rogers TMM 3 is a high-end test and measurement system that offers a wide range of capabilities, high accuracy and precision, a user-friendly interface, a wide frequency range, and a modular design. These features make it an ideal tool for demanding applications in the telecommunications industry.

Applications of Rogers TMM 3

Rogers TMM 3 is a powerful tool that has numerous applications in the field of microwave engineering. The following are some of the most common applications of Rogers TMM 3:

-

Antenna Design: Rogers TMM 3 is widely used for designing antennas because of its excellent electrical properties. The material has a low dielectric constant and loss tangent, making it ideal for high-frequency applications where signal loss is a concern. The material’s low thermal coefficient of expansion also makes it suitable for use in antennas that are exposed to extreme temperatures.

-

RF and Microwave Components: Rogers TMM 3 is also used for designing RF and microwave components such as filters, couplers, and amplifiers. The material’s low loss tangent and high thermal stability make it ideal for use in high-power applications where heat dissipation is a concern.

-

Satellite Communications: Rogers TMM 3 is commonly used in satellite communications systems because of its excellent electrical properties and resistance to thermal cycling. The material’s low dielectric constant and loss tangent make it ideal for use in satellite antennas and other components that require high-frequency performance.

-

Wireless Communication Systems: Rogers TMM 3 is also used in wireless communication systems such as cellular base stations and Wi-Fi routers. The material’s low loss tangent and high thermal stability make it ideal for use in high-power applications where heat dissipation is a concern.

In conclusion, Rogers TMM 3 is a versatile material that has numerous applications in the field of microwave engineering. Its excellent electrical properties, low loss tangent, and high thermal stability make it ideal for use in a wide range of applications, including antenna design, RF and microwave components, satellite communications, and wireless communication systems.

Technical Specifications

Physical Properties

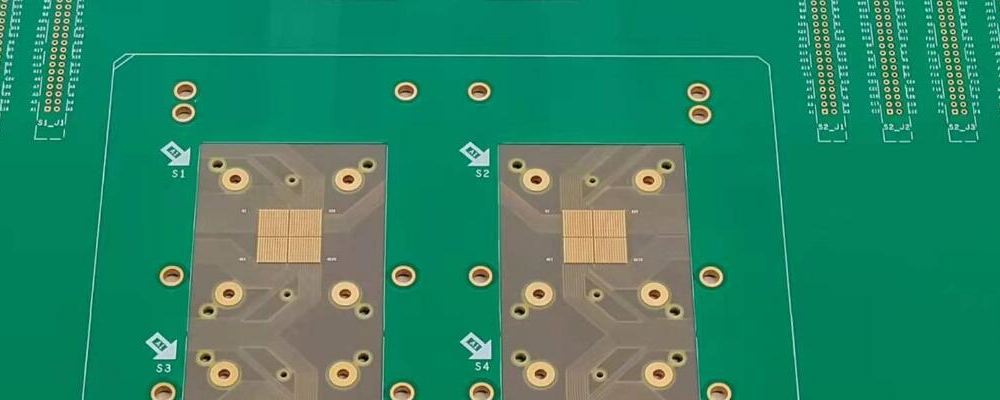

The Rogers TMM 3 is a high-performance microwave and radio frequency laminate material that offers excellent electrical and mechanical properties. It has a glass-reinforced hydrocarbon/ceramic composite substrate, with a thickness range of 0.002″ to 0.125″. The material is available in sheet form, with a standard sheet size of 24″ x 48″.

The TMM 3 material has a low dielectric constant and loss tangent, which makes it ideal for high-frequency applications. The dielectric constant ranges from 3.00 to 3.50, depending on the thickness of the substrate. The material also has a low coefficient of thermal expansion, which helps to minimize any dimensional changes due to temperature fluctuations.

Electrical Properties

The electrical properties of the Rogers TMM 3 are exceptional, making it a popular choice for high-frequency applications. The material has a low loss tangent, which means that it has low energy dissipation and is highly efficient. The loss tangent ranges from 0.0025 to 0.0028, depending on the thickness of the substrate.

The TMM 3 also has a high thermal conductivity, which helps to dissipate heat generated by high-power components. The thermal conductivity ranges from 0.7 to 1.0 W/mK, depending on the thickness of the substrate.

In addition, the material has a high glass transition temperature, which makes it suitable for use in high-temperature environments. The glass transition temperature is 280°C, which means that the material can withstand high temperatures without degrading.

Overall, the Rogers TMM 3 is a reliable and high-performance material that is suitable for a wide range of high-frequency applications. Its excellent electrical and mechanical properties make it a popular choice for designers and engineers who require high-performance materials for their applications.

Comparison with Other Models

The Rogers TMM 3 is a popular model used in project management. It stands out from other models due to its unique features and approach. In this section, we will compare the Rogers TMM 3 with other models to highlight its strengths and weaknesses.

Waterfall Model

The Waterfall model is a traditional approach to project management. It follows a linear sequence of phases, including requirements gathering, design, implementation, testing, and maintenance. Unlike the Rogers TMM 3, the Waterfall model does not allow for feedback loops or iterations. It assumes that all requirements are known upfront and that the project will progress in a predictable manner.

Agile Model

The Agile model is a flexible and iterative approach to project management. It emphasizes collaboration, customer satisfaction, and continuous delivery. Unlike the Rogers TMM 3, the Agile model does not have a formal process for requirements gathering or documentation. It relies on face-to-face communication and self-organizing teams to deliver value quickly.

Scrum Model

The Scrum model is a subset of the Agile model. It is a framework for managing and completing complex projects. It follows a set of ceremonies, including Sprint Planning, Daily Standup, Sprint Review, and Sprint Retrospective. Unlike the Rogers TMM 3, the Scrum model does not have a formal process for risk management or quality assurance. It relies on a Product Owner to prioritize and manage the backlog.

Kanban Model

The Kanban model is a visual approach to project management. It emphasizes flow, transparency, and continuous improvement. Unlike the Rogers TMM 3, the Kanban model does not have a formal process for requirements gathering or testing. It relies on a visual board to track work items and limit work in progress.

In conclusion, the Rogers TMM 3 offers a unique approach to project management. It combines the best practices from various models to provide a comprehensive and effective process. It allows for feedback loops, risk management, and quality assurance, while still being flexible and iterative.

User Experience

The Rogers TMM 3 is a popular tool among professionals for measuring the moisture content of various materials. The device is known for its ease of use and accurate readings. In this section, we will discuss the user experience of using the Rogers TMM 3.

One of the standout features of the TMM 3 is its simple and intuitive interface. The device is easy to navigate, and users can quickly access the various functions and settings. The large, backlit display is easy to read, even in low-light conditions. The device also features an audible alarm that alerts users when a reading has been taken, making it easy to keep track of measurements.

The TMM 3 is also designed with ergonomics in mind. The device is lightweight and comfortable to hold, even for extended periods. The rubberized grip ensures that the device won’t slip out of your hand, even if you’re working in damp or humid conditions.

Another key feature of the TMM 3 is its versatility. The device can be used to measure the moisture content of a wide range of materials, including wood, concrete, and drywall. The device is also compatible with a range of accessories, including external probes and sensors, which can be used to measure moisture in hard-to-reach areas.

Overall, the user experience of the Rogers TMM 3 is excellent. The device is easy to use, comfortable to hold, and provides accurate and reliable readings. Whether you’re a professional contractor or a DIY enthusiast, the TMM 3 is a valuable tool to have in your toolkit.

Maintenance and Troubleshooting

Regular maintenance is vital for keeping the Rogers TMM 3 in top condition and ensuring optimal performance. The following maintenance tasks should be performed on a regular basis:

- Cleaning: Regularly clean the instrument with a soft, dry cloth to remove dust and debris. Do not use water or cleaning products, as they may damage the device.

- Calibration: Calibrate the instrument regularly to ensure accurate measurements. Use the calibration kit provided with the device and follow the instructions carefully.

- Battery Replacement: Replace the batteries as soon as the low battery indicator appears on the display. Use only high-quality alkaline batteries to ensure optimal performance.

If you encounter any issues with the Rogers TMM 3, the following troubleshooting steps may help:

- Check the Batteries: Make sure the batteries are properly installed and have enough power.

- Check the Connections: Ensure that all cables and connections are properly connected and secure.

- Reset the Instrument: Try resetting the instrument by turning it off and then on again.

- Contact Technical Support: If the issue persists, contact technical support for further assistance.

In summary, regular maintenance and proper troubleshooting techniques are essential for keeping the Rogers TMM 3 in optimal condition and ensuring accurate measurements. By following the guidelines provided in the user manual, users can maximize the lifespan and performance of this valuable instrument.

Future Developments

As technology continues to evolve, Rogers TMM 3 is expected to undergo further advancements and developments. The company is committed to ongoing research and development to improve the performance and capabilities of the product.

One area of focus for future development is the integration of artificial intelligence (AI) and machine learning (ML) technology. This would allow the TMM 3 to automatically adjust its settings based on real-time data and feedback from the user, making it even more efficient and effective.

Another area of potential development is the expansion of the TMM 3’s capabilities to include additional types of testing. Currently, the TMM 3 is primarily used for testing the dielectric properties of materials, but there may be opportunities to expand into other areas such as thermal conductivity or mechanical properties.

Rogers is also exploring the possibility of making the TMM 3 more portable and user-friendly, with the goal of making it accessible to a wider range of users and applications. This could involve developing a smaller, more compact version of the TMM 3 or incorporating wireless connectivity and remote monitoring capabilities.

Overall, the future of Rogers TMM 3 looks bright, with ongoing developments and advancements expected to further improve its performance and capabilities.

Leave a Reply