Rogers 6010.2LM is a high-performance laminate material that is widely used in the aerospace and defense industries. It is known for its exceptional electrical properties, thermal stability, and mechanical strength. The material is manufactured using a proprietary process that ensures consistent quality and reliability.

One of the key features of Rogers 6010.2LM is its low dielectric constant and loss, which makes it ideal for high-frequency applications. The material also has excellent thermal stability, which allows it to maintain its electrical and mechanical properties over a wide temperature range. This makes it suitable for use in harsh environments, such as space and military applications.

In addition to its electrical and thermal properties, Rogers 6010.2LM also has excellent mechanical strength. It is resistant to impact, vibration, and other forms of mechanical stress, making it a reliable choice for demanding applications. Overall, Rogers 6010.2LM is a high-performance material that offers a unique combination of electrical, thermal, and mechanical properties, making it a popular choice in the aerospace and defense industries.

Rogers 6010.2LM Overview

Rogers 6010.2LM is a high-performance laminated material designed for use in high-frequency applications. It is a low-loss dielectric material that offers excellent electrical properties, making it ideal for use in demanding applications such as aerospace, defense, and telecommunications.

The Rogers 6010.2LM material is made up of a woven fiberglass reinforced composite with a ceramic filler. It has a dielectric constant of 10.2 and a dissipation factor of 0.0025 at 10 GHz. These properties make it an excellent choice for high-frequency applications where low loss and high stability are critical.

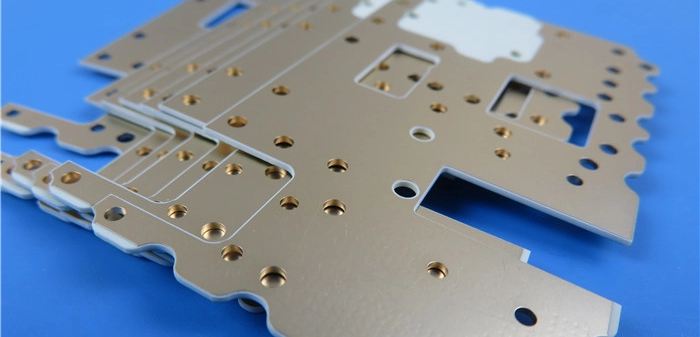

The material is available in a variety of thicknesses, ranging from 0.005 to 0.125 inches. It can be laminated with copper foil or other metal layers to create custom circuits and antennas. Rogers 6010.2LM is also compatible with a variety of fabrication methods, including drilling, routing, and laser cutting.

In addition to its excellent electrical properties, Rogers 6010.2LM also offers good mechanical stability and thermal performance. It has a low coefficient of thermal expansion, allowing it to maintain its dimensional stability over a wide temperature range. This makes it an excellent choice for use in harsh environments where temperature fluctuations are common.

Overall, Rogers 6010.2LM is a reliable and high-performance material for use in high-frequency applications. Its excellent electrical properties, combined with good mechanical stability and thermal performance, make it an ideal choice for demanding applications in aerospace, defense, and telecommunications.

Key Features of Rogers 6010.2LM

Material Characteristics

Rogers 6010.2LM is a low-loss laminate material with a dielectric constant (Dk) of 2.94 and a dissipation factor (Df) of 0.0025. It is made up of woven glass fabric and a ceramic-filled PTFE resin system. The material has a low coefficient of thermal expansion (CTE) of 17 ppm/°C in the z-axis, making it ideal for applications that require stable performance over a wide temperature range.

Electrical Properties

Rogers 6010.2LM has excellent electrical properties, including a low loss tangent of 0.0009 at 10 GHz and a high thermal conductivity of 0.8 W/mK. The material is also highly resistant to moisture absorption, with a moisture absorption rate of less than 0.04% by weight after 24 hours of exposure to boiling water.

Mechanical Properties

In addition to its excellent electrical properties, Rogers 6010.2LM also has impressive mechanical properties. The material has a tensile strength of 10,000 psi and a flexural strength of 18,000 psi, making it highly durable and resistant to damage. It also has a low coefficient of thermal expansion (CTE) of 17 ppm/°C in the z-axis, making it ideal for applications that require stable performance over a wide temperature range.

Overall, Rogers 6010.2LM is an excellent choice for high-frequency applications that require low loss, stable performance, and excellent mechanical properties. Its unique combination of material characteristics, electrical properties, and mechanical properties make it an ideal choice for a wide range of applications, including aerospace, defense, telecommunications, and more.

Applications of Rogers 6010.2LM

Rogers 6010.2LM is a high-performance, low-loss laminated substrate material that is widely used in various applications. This material offers excellent electrical properties, thermal stability, and mechanical strength, making it suitable for a wide range of applications.

Here are some of the common applications of Rogers 6010.2LM:

Radio Frequency (RF) and Microwave Applications

Rogers 6010.2LM is a popular choice for RF and microwave applications due to its low dielectric loss and high thermal stability. This material is commonly used in high-frequency circuits, such as antennas, power amplifiers, and filters.

Aerospace and Defense

Rogers 6010.2LM is also used in aerospace and defense applications, where high reliability and performance are critical. This material is used in radar systems, satellite communication systems, and other high-performance electronic systems.

Automotive Radar Systems

Rogers 6010.2LM is also used in automotive radar systems, which are becoming increasingly important for advanced driver assistance systems (ADAS) and autonomous vehicles. This material offers excellent performance at high frequencies, making it suitable for radar applications.

Other Applications

Rogers 6010.2LM is also used in other applications, such as high-speed digital circuits, medical equipment, and telecommunications. This material is suitable for applications that require high performance, reliability, and thermal stability.

Overall, Rogers 6010.2LM is a versatile and reliable material that is widely used in various applications. Its excellent electrical properties, thermal stability, and mechanical strength make it a popular choice for high-performance electronic systems.

Handling and Storage of Rogers 6010.2LM

Rogers 6010.2LM is a high-performance laminate material used in a variety of applications such as aerospace, military, and telecommunications. Proper handling and storage of this material are critical to ensure its optimal performance and longevity.

Handling

When handling Rogers 6010.2LM, it is important to follow the manufacturer’s guidelines to prevent damage to the material. Here are some general guidelines to consider when handling this material:

- Wear gloves to prevent oil and dirt from getting on the surface of the material.

- Use clean, dry tools to cut, drill, or machine the material.

- Avoid bending or flexing the material, as it can result in cracks or delamination.

- Do not expose the material to excessive heat or moisture, as it can affect the material’s properties.

Storage

Proper storage of Rogers 6010.2LM is crucial to prevent damage and ensure its optimal performance. Here are some guidelines to consider when storing this material:

- Store the material in a dry, clean, and temperature-controlled environment.

- Avoid exposing the material to direct sunlight or other sources of UV radiation.

- Store the material flat or on a roll, depending on the size and shape of the material.

- Keep the material in its original packaging until ready to use.

Following these guidelines can help ensure the optimal performance and longevity of Rogers 6010.2LM.

Safety Precautions

When working with Rogers 6010.2LM, it is important to take certain safety precautions to minimize the risk of injury or damage. Here are some guidelines to follow:

Personal Protective Equipment (PPE)

Always wear the appropriate personal protective equipment when handling Rogers 6010.2LM. This includes safety glasses, gloves, and a respirator or dust mask. The respirator or dust mask should be rated for protection against dust and fumes.

Handling and Storage

When handling Rogers 6010.2LM, use caution to avoid dropping or damaging the material. It is recommended to store the material in a cool, dry place to prevent moisture absorption and degradation of the material’s properties.

Cutting and Machining

When cutting or machining Rogers 6010.2LM, use appropriate tools and techniques to prevent overheating and damage to the material. Always use sharp tools and avoid excessive heat buildup. It is recommended to use coolant or lubricant during machining to prevent overheating.

Disposal

Rogers 6010.2LM should be disposed of in accordance with local regulations. Do not burn or incinerate the material, as this can release toxic fumes. Instead, dispose of the material in an appropriate waste disposal facility.

By following these safety precautions, you can minimize the risk of injury or damage when working with Rogers 6010.2LM.

Conclusion

In conclusion, Rogers 6010.2LM is a reliable and high-quality material for various applications. Its excellent dielectric properties make it a popular choice for electronic and RF applications. The low moisture absorption and high thermal stability make it suitable for use in harsh environments.

The material’s mechanical properties, including its high tensile strength and low compression set, also make it a great option for applications that require durability and long-term performance. Additionally, the material’s chemical resistance and low outgassing properties make it ideal for use in aerospace and defense applications.

Overall, Rogers 6010.2LM is a versatile material that offers a range of benefits for various applications. Its unique properties and excellent performance make it a reliable choice for engineers and manufacturers looking for high-quality materials.

Leave a Reply