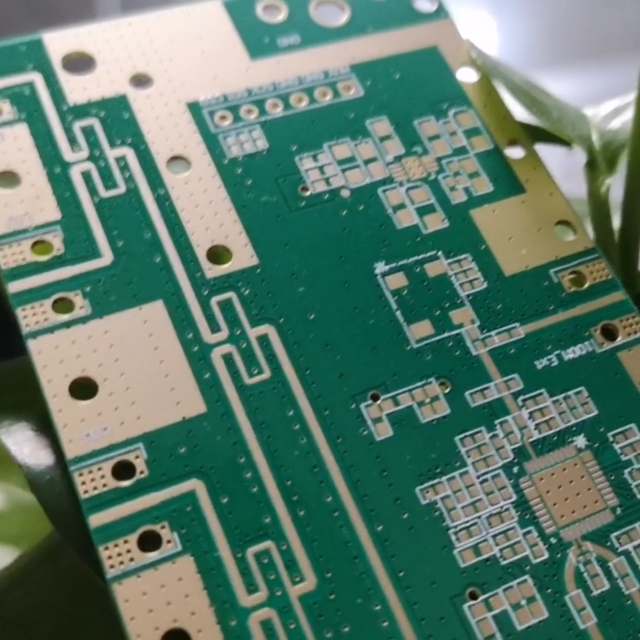

Rogers RO4003C is a high-frequency circuit material that is widely used in the electronics industry. It is a type of laminate material that is designed to provide excellent electrical performance at high frequencies. The material is made of a woven glass fabric that is impregnated with a high-temperature resin. This makes it highly durable and resistant to wear and tear.

One of the key features of Rogers RO4003C is its low dielectric loss. This means that it is able to maintain its electrical properties even at high frequencies, making it ideal for use in high-speed digital and RF applications. It also has a low dissipation factor, which helps to reduce signal loss and improve overall performance. In addition, the material is highly stable over a wide range of temperatures, making it suitable for use in extreme environments.

Overall, Rogers RO4003C is a reliable and high-performance circuit material that is widely used in the electronics industry. Its unique properties make it ideal for a range of applications, from high-speed digital to RF and microwave circuits. As technology continues to advance, it is likely that we will see even more widespread use of this material in the years to come.

Overview of Rogers RO4003C

Rogers RO4003C is a high-frequency laminate material used in the manufacturing of PCBs (Printed Circuit Boards) for applications that require stable electrical performance over a wide range of temperatures. It is a ceramic-filled hydrocarbon material that combines low dielectric loss with excellent thermal conductivity.

The material is designed to provide a low-cost alternative to PTFE (Polytetrafluoroethylene) laminates while maintaining similar electrical performance characteristics. RO4003C has a dielectric constant (Dk) of 3.38 and a dissipation factor (Df) of 0.0027 at 10 GHz. It is available in a range of thicknesses, from 8 mils to 125 mils.

RO4003C laminate material is compatible with standard PCB fabrication processes, including drilling, routing, and plating. It is also compatible with lead-free soldering processes, making it an excellent choice for RoHS (Restriction of Hazardous Substances) compliant applications.

The material is widely used in high-frequency applications, including aerospace and defense, telecommunications, and automotive industries. It is also used in microwave and millimeter-wave applications, such as radar systems, satellite communications, and wireless networks.

In summary, Rogers RO4003C is a high-frequency laminate material that offers excellent electrical performance, thermal conductivity, and compatibility with standard PCB fabrication processes. It is a cost-effective alternative to PTFE laminates and is widely used in a range of high-frequency applications.

Key Features of Rogers RO4003C

Electrical Properties

Rogers RO4003C is a high-frequency laminate material that has excellent electrical properties. Here are some key features:

- Low dielectric constant (Dk) of 3.38

- Low loss tangent (Df) of 0.0027

- High thermal conductivity of 0.8 W/mK

- High glass transition temperature (Tg) of 280°C

These properties make Rogers RO4003C an ideal choice for high-frequency applications, such as RF and microwave circuits. The low Dk and Df values ensure low signal loss and high signal integrity, while the high thermal conductivity and Tg values provide excellent stability and reliability under high-temperature conditions.

Mechanical Properties

In addition to its excellent electrical properties, Rogers RO4003C also has some impressive mechanical properties. Here are some key features:

- High tensile strength of 130 MPa

- High flexural strength of 240 MPa

- Low coefficient of thermal expansion (CTE) of 17 ppm/°C

These properties make Rogers RO4003C a durable and reliable material for a wide range of applications. The high tensile and flexural strength values ensure that the material can withstand mechanical stress and deformation, while the low CTE value ensures that the material maintains its dimensional stability over a wide temperature range.

Overall, Rogers RO4003C is a high-performance laminate material that offers excellent electrical and mechanical properties for high-frequency applications. Its combination of low Dk and Df values, high thermal conductivity and Tg values, and high tensile and flexural strength values make it an ideal choice for a wide range of demanding applications.

Applications of Rogers RO4003C

Rogers RO4003C is a high-frequency circuit material that offers excellent electrical performance and mechanical stability, making it ideal for a wide range of applications. Here are some of the common applications of Rogers RO4003C:

1. Telecommunications

Rogers RO4003C is widely used in the telecommunications industry for high-frequency applications such as antennas, filters, and amplifiers. Its low loss tangent and high dielectric constant make it suitable for high-speed data transmission and wireless communication systems.

2. Aerospace and Defense

Rogers RO4003C is also used in the aerospace and defense industry for applications such as radar systems, satellite communication systems, and electronic warfare. Its high reliability, thermal stability, and low outgassing properties make it ideal for harsh environments.

3. Automotive

Rogers RO4003C is becoming increasingly popular in the automotive industry for applications such as radar sensors, collision avoidance systems, and infotainment systems. Its high thermal conductivity and low coefficient of thermal expansion make it suitable for high-temperature environments.

4. Medical

Rogers RO4003C is also used in the medical industry for applications such as medical imaging and diagnostic equipment. Its high dielectric constant and low loss tangent make it suitable for high-frequency signals, while its biocompatibility ensures that it is safe for use in medical devices.

In conclusion, Rogers RO4003C is a versatile material that finds application in various industries due to its excellent electrical performance and mechanical stability.

Handling and Processing of Rogers RO4003C

Rogers RO4003C is a high-performance circuit board material that requires careful handling and processing to ensure optimal performance. Here are some tips for handling and processing Rogers RO4003C:

-

Storage: Rogers RO4003C should be stored in a dry, clean environment at room temperature. Avoid exposure to direct sunlight, moisture, and dust. The material should be stored flat to prevent warping or bending.

-

Cutting: Rogers RO4003C can be cut using a variety of methods, including CNC routing, laser cutting, and waterjet cutting. It is important to use the appropriate cutting tools and techniques to avoid delamination, chipping, or other damage to the material.

-

Drilling: When drilling holes in Rogers RO4003C, it is important to use sharp, high-quality drill bits and to avoid excessive heat buildup. Preheating the material can help reduce the risk of delamination or burrs.

-

Cleaning: Rogers RO4003C should be cleaned using a mild detergent and water or a specialized cleaning solution. Avoid using abrasive cleaners or solvents that can damage the material.

-

Soldering: Rogers RO4003C can be soldered using standard soldering techniques, such as reflow soldering or wave soldering. It is important to use appropriate flux and to avoid excessive heat, which can cause delamination or warping.

Overall, handling and processing Rogers RO4003C requires attention to detail and a careful approach. By following the recommended guidelines, you can ensure that your circuit boards perform optimally and reliably.

Comparative Analysis

When it comes to high-frequency circuit materials, Rogers RO4003C is a popular choice among designers. However, it’s always a good idea to compare its features and performance with other options available in the market. In this section, we will take a closer look at how RO4003C compares to some of its competitors.

RO4003C vs. RO4350B

RO4350B is another high-frequency circuit material from Rogers Corporation. It has a similar dielectric constant and loss tangent as RO4003C, but it offers better thermal conductivity and a higher glass transition temperature. This means that RO4350B can handle higher power levels and operate at higher temperatures without significant performance degradation. On the other hand, RO4003C is less expensive and has a lower coefficient of thermal expansion, which makes it more suitable for applications that require dimensional stability.

RO4003C vs. Isola FR408

Isola FR408 is a popular alternative to Rogers RO4003C. It has a similar dielectric constant and loss tangent, but it offers better thermal performance and lower moisture absorption. FR408 is also compatible with lead-free soldering processes, which makes it more environmentally friendly. However, FR408 is more expensive than RO4003C and has a higher coefficient of thermal expansion, which may limit its use in some applications.

RO4003C vs. Arlon AD450

Arlon AD450 is another high-frequency circuit material that competes with Rogers RO4003C. AD450 has a lower dielectric constant and loss tangent than RO4003C, which makes it more suitable for applications that require low signal loss. However, AD450 has a lower thermal conductivity and glass transition temperature, which limits its power handling capability and operating temperature range. AD450 is also more expensive than RO4003C, which may make it less attractive to designers who are cost-conscious.

In summary, Rogers RO4003C is a versatile high-frequency circuit material that offers a good balance of performance and cost-effectiveness. While there are other options available in the market with different strengths and weaknesses, RO4003C remains a popular choice among designers for a wide range of applications.

Conclusion

In conclusion, Rogers RO4003C is a high-performance material that offers excellent electrical and mechanical properties for RF and microwave applications. With its low dielectric loss and high thermal conductivity, it provides stable and reliable performance even in high-frequency and high-temperature environments.

The material’s low moisture absorption and tight thickness tolerance make it suitable for use in various applications, including power amplifiers, filters, and antennas. Its compatibility with various processing techniques, such as drilling, routing, and laser cutting, offers flexibility and ease of use for manufacturers.

Rogers RO4003C’s high-performance characteristics come at a cost, making it a premium material compared to other PCB substrates. However, its benefits in terms of performance and reliability make it a worthwhile investment for high-frequency and high-power applications.

Overall, Rogers RO4003C is a reliable and high-performance material that offers excellent electrical and mechanical properties for RF and microwave applications. Its compatibility with various processing techniques and its ability to withstand high temperatures and frequencies make it a popular choice among manufacturers.

Leave a Reply