Introduction to PCB Files

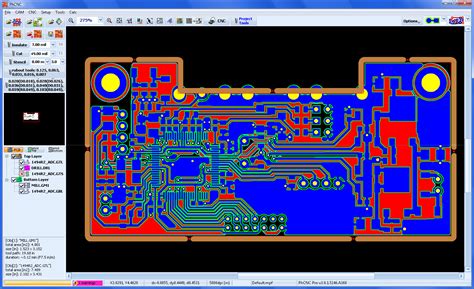

A PCB file, short for Printed Circuit Board file, is a digital document that contains all the necessary information and data required to design and manufacture a printed circuit board. PCB files are created using specialized software tools known as EDA (Electronic Design Automation) or ECAD (Electronic Computer-Aided Design) software. These files are essential for the design, prototyping, and production of electronic devices and systems.

PCB files contain a wide range of information, including the schematic diagram, component placement, routing, and mechanical details of the board. They also include the necessary manufacturing instructions, such as drill holes, copper traces, and solder mask layers. The primary purpose of a PCB file is to provide a complete and accurate representation of the circuit board, which can be used by manufacturers to produce the physical board.

Types of PCB Files

There are several types of PCB files, each serving a specific purpose in the design and manufacturing process. Some of the most common types of PCB files include:

1. Gerber Files (.gbr)

Gerber files, also known as RS-274X files, are the most widely used format for PCB manufacturing. These files contain the necessary information for each layer of the PCB, such as copper traces, solder mask, and silkscreen. Gerber files are created by exporting the PCB design from the EDA software and are used by manufacturers to create the physical board.

2. Drill Files (.drl)

Drill files contain information about the location, size, and type of holes that need to be drilled into the PCB. These holes are used for mounting components, creating vias, and providing mechanical support. Drill files are typically generated in the Excellon format and are used in conjunction with Gerber files to manufacture the board.

3. ODB++ Files (.tgz)

ODB++, or Open Database++, is a comprehensive PCB data format that includes all the necessary information for manufacturing, assembly, and testing. ODB++ files are created by packaging Gerber, drill, and other related files into a single compressed archive. This format is gaining popularity due to its ability to streamline the PCB manufacturing process and reduce errors.

4. IPC-2581 Files (.xml)

IPC-2581 is an open, neutral format for exchanging PCB design data. It is based on the XML (eXtensible Markup Language) and includes all the necessary information for manufacturing, assembly, and testing. IPC-2581 files are intended to replace the multiple file formats used in the PCB industry, such as Gerber and drill files, with a single, unified format.

PCB Design Software and File Creation

To create PCB files, designers use specialized software tools known as EDA or ECAD software. These tools allow designers to create schematic diagrams, layout the components, and route the connections between them. Some of the most popular PCB design software include:

- Altium Designer

- KiCad

- Eagle

- OrCAD

- Mentor Graphics PADS

When designing a PCB, the first step is to create a schematic diagram that represents the electrical connections between the components. The schematic is then used to create a netlist, which is a list of all the components and their connections. The netlist is imported into the PCB layout software, where the designer places the components and routes the connections between them.

Once the PCB layout is complete, the designer can generate the necessary manufacturing files, such as Gerber and drill files. These files are then sent to the manufacturer, who uses them to create the physical board.

PCB Manufacturing Process

The PCB manufacturing process involves several steps, each of which relies on the information contained in the PCB files. The main steps in the PCB manufacturing process include:

-

PCB Fabrication: The first step is to create the bare PCB board using the Gerber files. This involves applying a layer of copper to the substrate material, etching away the unwanted copper to create the traces and pads, and applying a solder mask and silkscreen.

-

Drilling: Using the drill files, holes are drilled into the PCB for mounting components, creating vias, and providing mechanical support.

-

Component Placement: The components are placed onto the PCB using automated pick-and-place machines. The machines use the component placement information from the PCB files to accurately position the components on the board.

-

Soldering: The components are then soldered onto the PCB using either through-hole or Surface-Mount Technology. Through-hole components are inserted into the drilled holes and soldered in place, while surface-mount components are placed directly onto the pads and soldered using a reflow oven.

-

Inspection and Testing: After the components are soldered, the PCB undergoes a series of inspections and tests to ensure that it functions correctly. This may include visual inspections, automated optical inspections (AOI), and electrical tests such as in-circuit testing (ICT) and functional testing.

PCB File Formats and Their Advantages

Each PCB file format has its own advantages and disadvantages, depending on the specific requirements of the design and manufacturing process. Here are some of the key advantages of each format:

Gerber Files

- Widely supported by PCB manufacturers

- Simple and easy to generate

- Compact file size

- Can be viewed and edited using a variety of software tools

Drill Files

- Provide precise information about hole locations and sizes

- Essential for creating vias and Mounting holes

- Compatible with most PCB manufacturing equipment

ODB++ Files

- Comprehensive format that includes all necessary manufacturing data

- Reduces the number of files needed for manufacturing

- Improves data integrity and reduces errors

- Supports advanced features such as embedded components and sequential lamination

IPC-2581 Files

- Open, neutral format that promotes data exchange between different software tools

- Includes all necessary manufacturing, assembly, and testing data in a single file

- Reduces the risk of errors and inconsistencies

- Supports advanced features such as 3D models and material stackups

Best Practices for Creating PCB Files

To ensure that your PCB files are accurate, complete, and compatible with the manufacturing process, follow these best practices:

- Use a consistent naming convention for your files and layers

- Include all necessary files, such as Gerber, drill, and netlist files

- Verify that your files are free of errors and conform to the manufacturer’s specifications

- Use a 1:1 scale when creating your PCB layout to avoid scaling issues

- Include adequate clearances and tolerances to ensure manufacturability

- Specify the correct units and format for your files

- Use a reliable file transfer method, such as FTP or secure email, to send your files to the manufacturer

Frequently Asked Questions (FAQ)

1. What is the difference between Gerber and ODB++ files?

Gerber files are the traditional format for PCB manufacturing and include separate files for each layer of the board, such as copper, solder mask, and silkscreen. ODB++, on the other hand, is a more comprehensive format that includes all the necessary manufacturing data in a single compressed archive. ODB++ files are more efficient and reduce the risk of errors, but they may not be supported by all manufacturers.

2. Can I create PCB files using any EDA software?

Most EDA software tools can create PCB files in a variety of formats, including Gerber, drill, and ODB++. However, some tools may have limited support for certain formats or may require additional plugins or extensions. It’s important to choose an EDA software that is compatible with your manufacturing process and supports the necessary file formats.

3. What happens if my PCB files are incomplete or contain errors?

If your PCB files are incomplete or contain errors, it can delay the manufacturing process and increase the risk of defects or failures. The manufacturer may need to contact you for clarification or request additional files, which can add time and cost to the project. To avoid these issues, it’s important to carefully review your files and ensure that they are complete, accurate, and conform to the manufacturer’s specifications.

4. Can I use the same PCB files for different manufacturing processes?

In general, the same PCB files can be used for different manufacturing processes, such as prototype and production runs. However, there may be some differences in the requirements for each process, such as the minimum feature size or the number of layers. It’s important to communicate with your manufacturer and ensure that your files are suitable for the specific process you are using.

5. How can I ensure the security and confidentiality of my PCB files?

PCB files contain sensitive information about your product design and intellectual property. To ensure the security and confidentiality of your files, you should use secure file transfer methods, such as FTP or encrypted email, and require your manufacturer to sign a non-disclosure agreement (NDA). You should also be careful about sharing your files with unauthorized third parties or posting them on public forums or websites.

Conclusion

PCB files are essential for the design, prototyping, and manufacturing of printed circuit boards. They contain all the necessary information and data required to create the physical board, including the schematic diagram, component placement, routing, and mechanical details. There are several types of PCB files, each serving a specific purpose in the manufacturing process, such as Gerber, drill, ODB++, and IPC-2581 files.

To create PCB files, designers use specialized EDA or ECAD software tools, which allow them to create schematic diagrams, layout the components, and generate the necessary manufacturing files. The PCB manufacturing process involves several steps, each of which relies on the information contained in the PCB files, including fabrication, drilling, component placement, soldering, and inspection.

To ensure the accuracy, completeness, and compatibility of your PCB files, it’s important to follow best practices such as using a consistent naming convention, including all necessary files, verifying your files for errors, and specifying the correct units and format. By creating high-quality PCB files and communicating effectively with your manufacturer, you can streamline the PCB manufacturing process and ensure the success of your electronic product.

| File Format | Advantages | Disadvantages |

|---|---|---|

| Gerber | – Widely supported by manufacturers | – Requires separate files for each layer |

| – Simple and easy to generate | – Limited support for advanced features | |

| – Compact file size | ||

| Drill | – Precise hole location and size information | – Limited to hole data only |

| – Essential for vias and mounting holes | ||

| ODB++ | – Comprehensive manufacturing data | – May not be supported by all manufacturers |

| – Reduces number of files needed | – Requires specialized software to create and view | |

| – Improves data integrity and reduces errors | ||

| IPC-2581 | – Open, neutral format for data exchange | – Limited adoption in the industry |

| – Includes all necessary manufacturing data | – Requires specialized software to create and view | |

| – Supports advanced features (3D models, etc.) |

Leave a Reply