Introduction

The Rogers DiClad 527 is an exciting new copper alloy that is poised to revolutionize industrial applications requiring superior thermal and electrical conductivity. In this article, we will explore the key properties and performance benefits of this innovative alloy, and examine some of its most promising applications across industries ranging from electronics to renewables.

Overview of the Rogers DiClad 527 Alloy

The Rogers DiClad 527 belongs to a class of copper alloys known as dispersion-strengthened materials. It contains a fine dispersion of aluminum oxide nanoparticles within a pure copper matrix, giving it a unique combination of properties.

Some key features of the DiClad 527 alloy include:

- High thermal conductivity – nearly as conductive as pure copper

- High electrical conductivity – up to 100% IACS (International Annealed Copper Standard)

- Excellent resistance to softening and creep at high temperatures

- Good corrosion resistance and oxidation resistance

- Ease of forming and joining using standard methods for copper

- Consistent properties through the cross section due to its clad construction

The proprietary fabrication process used by Rogers Corporation results in an extremely fine and uniform distribution of the aluminum oxide nanoparticles, enabling the superior property combination.

| Property | Value |

|---|---|

| Density | 8.94 g/cm3 |

| Melting Point | 1083°C |

| Thermal Conductivity | Up to 380 W/m-K |

| Electrical Resistivity | 1.72 μΩ-cm |

| Tensile Strength | 260 MPa |

Table: Key properties of the Rogers DiClad 527 alloy.

This unique balance of thermal, electrical, and mechanical properties makes the DiClad 527 stands out among other copper alloys and pure metals, opening up new possibilities for industrial applications.

Industries and Applications

The Rogers DiClad 527 alloy provides an ideal solution for many demanding applications across a diverse range of industries. Some of the most promising uses include:

Power Electronics

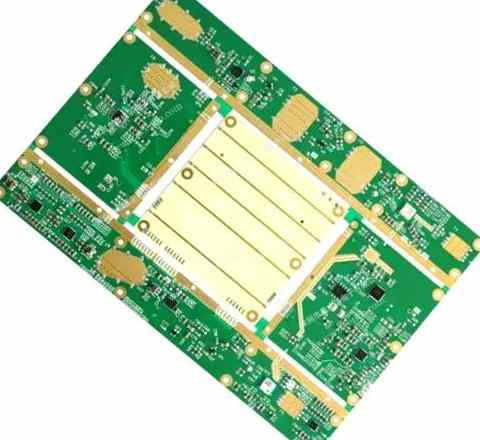

- Substrates for power semiconductor devices like IGBTs and MOSFETs

- Base plates and heat spreaders for power modules and converters

- Packaging for high-power density designs

The need to remove heat from power electronic components is critical. The high thermal conductivity allows efficient heat extraction, while the electrical conductivity enables optimal device performance.

Renewable Energy

- Wind turbine slip ring assemblies

- Solar cell interconnects

- Thermal management components

Renewable energy systems require reliable and consistent performance under challenging environmental conditions over long lifetimes. The DiClad 527 alloy’s stability, corrosion resistance, and consistent properties make it an excellent choice.

Industrial Heat Exchangers

- Heat exchanger tubing

- Microchannel coolers

- Cold plates

With its high thermal conductivity and ease of fabrication into complex shapes, the DiClad 527 can enhance efficiency and reduce size/weight of industrial heat exchangers.

Electrical Power Distribution

- Bus bars

- High-current interconnects

- Switchgear components

For handling high electrical currents with minimal power losses, the high conductivity and ampacity of this alloy outperforms other alternatives.

Additional Applications

- Aerospace actuators

- Nuclear control rod drive mechanisms

- Induction heating components

- Thermal management devices

- High-field magnets

The unique properties of this alloy continue to spur innovative uses across many fields.

In summary, the Rogers DiClad 527 enables lighter, more compact and higher-performance solutions to thermal and electrical challenges faced in modern high-tech industrial applications.

Manufacturing and Machining

A key benefit of the DiClad 527 alloy is that it can be fabricated, formed and joined using standard processes and techniques for copper. This allows it to be easily incorporated into manufacturing operations.

Some examples of feasible manufacturing methods include:

- Flat rolling to sheets and plates

- Extrusion into rods, bars and complex profiles

- Deep drawing into various formed parts

- Welding using processes like gas tungsten arc welding (GTAW)

- Soldering and brazing for joints

- Drilling, milling, turning and other conventional machining

The alloy can also be plated using standard copper plating techniques to allow soldering or provide corrosion resistance.

These familiar copper working processes allow manufacturers to avoid specialized equipment or training when adopting the DiClad 527 alloy into their products.

Availability

The Rogers DiClad 527 alloy is distributed globally through a network of channel partners and distributors. It is available in sheet, plate, rod, wire and other stock forms to suit different applications.

Some available product variations include:

- DiClad 527 (Alloy 527 clad with OFHC copper on both sides)

- Alloy 527 (pure dispersion-strengthened copper)

- DiClad 524 (Alloy 524 clad with OFHC copper on both sides)

Custom shapes, sizes and forms can also be sourced for large volume demands.

Overall, the expanding supply chain availability of this novel copper alloy makes it readily accessible for companies worldwide to take advantage of its unique benefits.

Cost Considerations

As an advanced engineered copper alloy, the Rogers DiClad 527 comes at a higher cost compared to alternatives like OFHC copper or copper alloys such as brass or bronze.

However, for many applications the superior properties justify the cost premium, as it leads to:

- Improved performance – more power, faster processing etc.

- Longer working life of components

- Reduced system size and weight

In addition, the alloy can often enable simplified designs by removing the need for protective coatings or multiple components.

For manufacturers, the higher material cost of DiClad 527 is usually offset by production or operational benefits. Prototyping is recommended to determine the feasibility for specific applications.

Investing in this high-performance alloy can pay dividends over the lifetime of critical industrial systems and devices.

Future Outlook

As an enabling technology for next-generation designs, the interest and adoption of the Rogers DiClad 527 alloy continues to grow rapidly.

The unique balance of properties allows engineers to push the boundaries of what is possible with copper. New applications are continually emerging as companies innovate with this versatile material.

With Industry 4.0 and demands for mobility and miniaturization across sectors, copper alloys like DiClad 527 will become increasingly critical. They provide compact, efficient and robust solutions to evolving technological challenges.

Rogers Corporation continues to invest in expanding awareness and availability of the alloy globally, ensuring its benefits can be realized broadly across industries.

The future looks bright for broader adoption of the Rogers DiClad 527, powering innovation and progress in industrial technology.

Frequently Asked Questions

Here are some common questions about the Rogers DiClad 527 alloy:

What makes the DiClad 527 unique compared to other copper alloys?

The very fine nanoparticle dispersion enables a combination of strength, thermal conductivity, and electrical conductivity that sets it apart from other copper alloys. It comes close to pure copper conductivity while still having good mechanical properties.

What are some key benefits over aluminum or stainless steel?

It provides higher thermal and electrical conductivity than aluminum or stainless steel. The high ampacity allows smaller conductors to be used. It is also much lighter than steel for equivalent performance.

What are some example applications in renewable energy?

Wind turbine slip rings, solar cell bus bars and interconnects, thermal pipes for solar receivers, PEM fuel cell plates are some renewable energy uses.

Does it require special tools or techniques to machine?

No, it can be machined using standard copper machining techniques. Tooling wear may be slightly higher than pure copper.

What joining methods can be used?

It is readily weldable using GTAW, resistance welding, and other common methods used for copper. Brazing and soldering are also effective for joining.

Is the alloy available in forms other than sheet?

Yes, rod, plate, wire, and customized forms are also available from Rogers Corporation and its distributors.

Conclusion

With its compelling combination of thermal, electrical and mechanical properties, the Rogers DiClad 527 alloy represents an enabling technology that unlocks innovation across many demanding industrial applications. Driven by its unmatched capabilities, this alloy will become a vital solution as companies push the boundaries of next-generation designs. Its unique benefits make the higher cost well worthwhile for superior lifetime performance. As availability and awareness of this material expands globally, its adoption will continue to accelerate. The Rogers DiClad 527 alloy will power rapid advancements in technology across sectors.

Leave a Reply