An Overview of Rogers curamik CoolEasy Technology

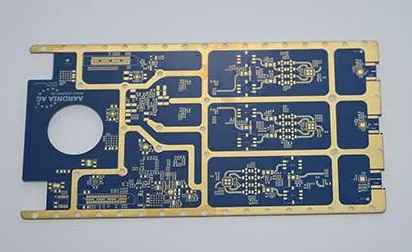

Rogers curamik CoolEasy is an innovative direct bonded copper (DBC) substrate technology developed by Rogers Corporation. It offers several benefits compared to traditional DBC substrates, making it an attractive option for power electronic applications.

How Does CoolEasy Technology Work?

The CoolEasy substrate consists of a ceramic insulator, commonly aluminum nitride (AlN), with thin layers of copper bonded to either side. The key difference from standard DBCs is that the copper is directly bonded to the ceramic at low temperature, without the need for a high-temperature sintering process.

This enables a number of advantages:

- Lower residual stress – The low temperature bonding process induces less residual stress between the copper and ceramic layers. This improves reliability and robustness.

- Thinner ceramic – The ceramic insulator can be made thinner than a typical sintered DBC, improving thermal performance.

- Lower cost – Eliminating high temperature sintering reduces manufacturing costs.

Benefits of CoolEasy Substrates

The CoolEasy technology brings some significant benefits compared to conventional DBCs:

- Excellent thermal performance – The thin ceramic and direct copper bonding provides very efficient heat spreading and low thermal resistance.

- High reliability – Lower residual stresses improve resistance to thermal cycling and reduce likelihood of delamination.

- Lower inductance – Thinner dielectric material reduces parasitic inductance.

- Lower cost – Manufacturing cost savings from eliminating sintering process.

- Fabrication flexibility – DBCs can be fabricated in different thickness combinations.

Applications of CoolEasy Technology

The properties of CoolEasy DBCs make them well suited to a range of power electronic applications:

- IGBT power modules – Used extensively in power conversion, motor drives, etc.

- LED lighting – Efficient cooling is critical for high power LEDs.

- Automotive – Improved reliability important in automotive electronics.

- Renewable energy – Wind and solar inverters operate under demanding conditions.

- Industrial – CoolEasy provides robustness for industrial electronics.

With its advantages over conventional DBCs, CoolEasy technology delivers higher performance and reliability at lower cost, making it an appealing choice for modern power electronic systems.

Key Properties of CoolEasy Substrates

Here are some of the key properties and capability of Rogers curamik CoolEasy DBC technology:

Thermal Performance

- Thermal conductivity up to 200 W/mK

- Low thermal resistance – as low as 0.3 K/W

- High power capability – over 1000 W/cm2

Electrical Properties

- Dielectric strength > 20 kV/mm

- Volume resistivity > 10^14 Ohm-cm

- Dielectric constant ~ 8.5

Mechanical Properties

- Flexural strength > 350 MPa

- Compressive strength > 300 MPa

- Tensile strength > 30 MPa

Dimensions

- Ceramic thickness down to 0.1 mm

- Copper thickness from 0.2 to 2.0 mm

- Large substrates up tocommits. 147 x 245 mm

Key Reliability Aspects

- Thermal cycling capability > 2000 cycles

- Thermal shock resistance

- High insulation resistance

- Resistance to humidity

Frequently Asked Questions

Here are some common questions about Rogers curamik CoolEasy technology:

What are the main benefits of CoolEasy vs standard DBC?

The advantages of CoolEasy are lower thermal resistance, higher reliability, lower parasitic inductance, thinner dielectric, and lower cost by eliminating high temperature sintering.

What ceramic materials can be used for CoolEasy?

The most common ceramic is aluminum nitride (AlN). Beryllium oxide (BeO) can also be used. These have high thermal conductivity.

Can CoolEasy handle high temperature processes?

Yes, CoolEasy can withstand soldering temperatures up to 300°C and is also suitable for high temperature SiC applications.

Does CoolEasy use any dielectric layers?

No, there are no extra dielectric layers used. The ceramic insulator itself acts as the dielectric.

What copper thicknesses are available?

CoolEasy supports copper thicknesses ranging from 0.2 mm to 2.0 mm. Thinner copper improves thermal performance.

In summary, Rogers curamik CoolEasy enables high performance and reliable direct bonded copper substrates without high temperature sintering. Its advantages make it an attractive option for many power electronic applications requiring excellent thermal management.

Leave a Reply