Introduction

The Rogers CuClad 6250 bonding film is a proprietary composite material developed by Rogers Corporation for multilayer printed circuit board (PCB) fabrication using low temperature lamination processes. As PCBs become increasingly complex with higher layer counts and denser interconnects, materials like CuClad 6250 enable reliable bonding of circuit layers without damaging heat-sensitive components.

This article provides an in-depth look at CuClad 6250, including its properties, applications, benefits, and processing guidelines. Useful information is provided for PCB designers considering this material for their multilayer boards.

What is CuClad 6250?

Rogers CuClad 6250 is a cyanate ester based bonding film reinforced with glass fabric. Its low flow characteristics combined with high adhesion make it well-suited for multilayer PCB constructions requiring low lamination temperatures.

Some key properties of CuClad 6250 include:

- Glass transition temperature (Tg): 270°C

- Decomposition temperature: >300°C

- X-Y CTE: 60-65 ppm/°C

- Z-axis CTE: 140-180 ppm/°C

- Dielectric constant (Dk) at 10 GHz: 3.5

- Loss tangent at 10 GHz: 0.015

- Bonding film thickness: 0.002-0.004 inches (2-4 mils)

Composition

The CuClad 6250 film consists of cyanate ester resin blended with a woven glass fabric reinforcement. The glass fabric lends dimensional stability while the cyanate ester provides adhesion and flow during bonding.

A thin layer of electrodeposited copper is present on both sides of the film. This integral copper cladding enables electrical connections and soldering.

Applications and Benefits

CuClad 6250 offers several benefits that make it well-suited for a range of PCB applications:

Multilayer PCB Construction

The low flow characteristics of CuClad 6250 enable excellent bonding between layers without excessive resin squeeze out. This allows the construction of multilayer boards with high layer counts.

Heat Dissipation

With a glass transition temperature of 270°C, CuClad 6250 maintains stability and dielectric properties at higher temperatures required for heat dissipation in power electronic devices.

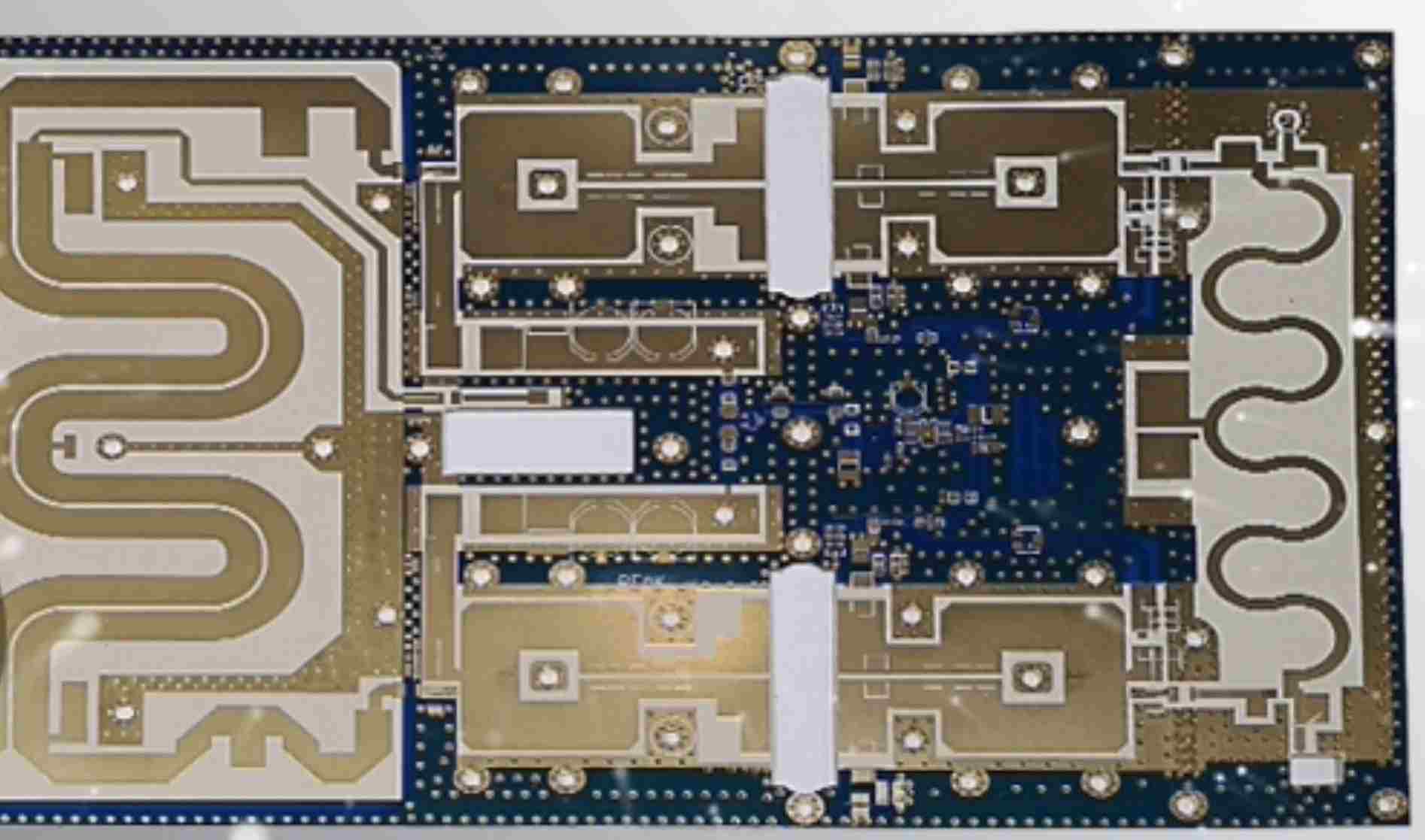

High Frequency Applications

The stable dielectric properties up to 10 GHz frequency range make this material suitable for RF/microwave boards requiring fine linewidths and spacing.

Low Temperature Lamination

The low melt viscosity of the cyanate ester resin enables multilayer bonding temperatures as low as 180°C. This prevents damage to heat-sensitive components on the PCB.

Fine Line Circuits

CuClad 6250 provides excellent dimensional stability and reduced shrinkage, enabling fine line circuits down to 3/3 mil line/space.

Flex-Rigid Applications

The low modulus and good adhesion allows the use of CuClad 6250 bonding ply in flex-rigid PCB constructions.

Processing Guidelines

To properly leverage the benefits of CuClad 6250 bonding film, PCB fabricators need to follow specific processing guidelines during multilayer lamination and drill/rout operations.

Lamination

- Recommended lamination temperature range is 180-200°C

- Pressure should be 300-500 psi

- Heating rate: 3-5°C/min

- Dwell time above 180°C: 60-120 minutes

Drilling

- Standard entry/exit materials can be used

- Use diamond-coated drills

- Surface speeds around 600-800 SFM work best

- Aluminum entry over epoxy glass exit is recommended

Routing

- Carbide tools with PTFE coatings are optimal

- 12,000-24,000 rpm spindle speeds preferred

- Multiple passes with small stepovers reduces chipping

- Use proper dust collection during routing

Hole Wall Preparation

- Desmear hole walls prior to metallization using permanganate process

- Optimize dwell times and temperatures during desmear for optimal resin removal

- No glass etchback required prior to electroless copper deposition

By following these processing guidelines, fabricators can achieve success with CuClad 6250 and avoid common pitfalls. Factors like lamination temperature, pressure and ramp rates are especially critical.

Comparison to FR-4

Rogers CuClad 6250 differs substantially from standard FR-4 bonding materials:

| Property | CuClad 6250 | FR-4 |

|---|---|---|

| Glass Transition Temperature | 270°C | 130-140°C |

| Decomposition Temperature | >300°C | >240°C |

| Dk at 10 GHz | 3.5 | 4.4-4.6 |

| Dissipation Factor at 10 GHz | 0.015 | 0.02 |

| Bonding Temperature | 180-200°C | 180-200°C |

| Dimensional Stability | Excellent | Moderate |

| Fine Line Capability | 3/3 mil lines/spaces | 5/5 mil minimum |

| Lead-free Soldering | Compatible | Limited Compatibility |

| Flex-Rigid Capability | Suitable | Challenging |

As seen above, the Rogers bonding film offers superior electrical and thermal performance compared to standard FR-4. The low loss, stable Dk, high Tg and improved dimensional stability of CuClad 6250 make it a better choice for advanced multilayer PCBs, especially in high frequency and temperature applications.

Cost Considerations

The advanced materials and processing used in CuClad 6250 lead to a higher cost compared to FR-4 bonding films. However, for complex multilayer boards, the performance benefits often justify the additional cost.

Here are some guidelines on where the extra cost is worth it:

- High layer count boards (>16 layers)

- Boards requiring fine features (<5 mil lines/spaces)

- High frequency boards (RF/microwave applications) -thermal management is critical (power electronics)

- Stability is paramount (aerospace/defense)

For standard density interconnect boards where electrical performance and thermals are not pushed to the limits, FR-4 remains the most cost-effective bonding film.

Conclusion

The Rogers CuClad 6250 thermoset bonding film enables reliable, high performance multilayer PCBs using low temperature lamination processes. The tightly controlled flow, stable dielectric properties, excellent dimensional stability and thin bonded interface make it an optimal choice when pushing the boundaries in density, speed and temperature requirements. By following the guidelines outlined here on properties, applications and processing, PCB designers can take full advantage of this advanced material’s capabilities for their complex multilayer boards.

Frequently Asked Questions

Q: What is the typical lead time for procuring CuClad 6250 bonding film?

A: The lead time is usually 4-6 weeks from order confirmation to delivery for standard CuClad 6250 films. For custom formulations tailored to specific applications, lead times may extend to 8-12 weeks.

Q: Can CuClad 6250 be used for sequential lamination?

A: Yes, CuClad 6250’s low flow properties make it suitable for sequential lamination processes often used in high layer count boards. The initial bonding ply should be a standard 6250 film, followed by a low flow version for subsequent layups.

Q: What drill sizes can be used with CuClad 6250 boards?

A: Micro-vias with diameters down to 150μm (6 mils) can be reliably drilled in CuClad 6250. The stable material properties ensure consistent, high quality laser drilling.

Q: Does CuClad 6250 require special via filling or plating processes?

A: Standard electroless copper plating processes work well with CuClad 6250 for filling blinds vias. The material’s smooth surfaces allow uniform copper deposition.

Q: Can Rogers CuClad 6250 be used for flex PCB applications?

A: Yes, CuClad 6250’s adhesive properties allow bonding of flex laminates. Polyimide films like DuPont Kapton are commonly used with 6250 bonding ply for flex-rigid boards.

Leave a Reply